Top 10 3D Printing Startups in India 2026

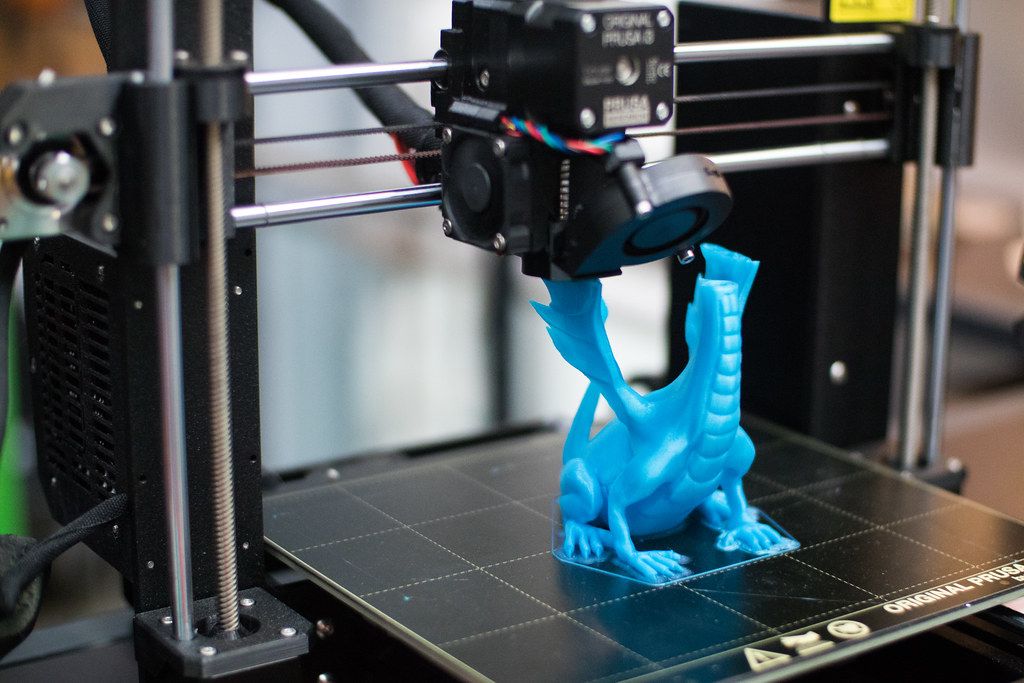

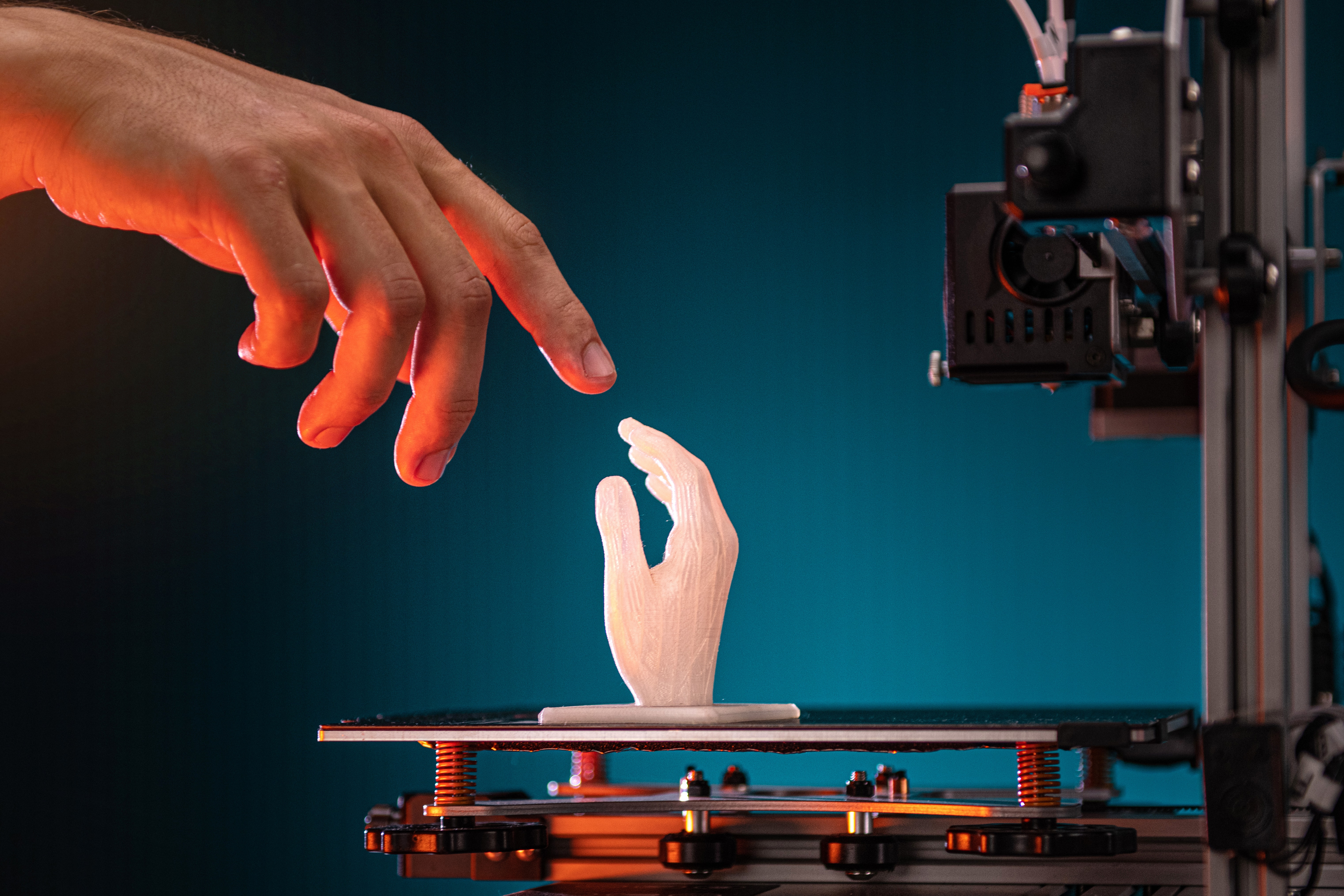

India’s 3D printing (Additive Manufacturing – AM) scene is exploding by 2026, driven by ‘Make in India’ & digital growth, with young startups innovating across aerospace, med-tech, automotive, and consumer goods, focusing on affordable, localized solutions, advanced materials (metals, composites), and bringing complex digital designs into physical reality, transforming traditional manufacturing with rapid prototyping, custom parts, and on-demand production, signaling a shift towards decentralized, agile production models.

1. Imaginarium (Mumbai)

Founded: 2009 by Kamlesh Parekh and Dipak Shah.

Core Technologies: A one-stop additive manufacturing hub with industrial 3D printers (SLA, SLS, DLP, MJF, etc.) and allied services like casting and CNC machining.

Key Sectors: Jewellery (through its Imaginarium Precious unit), automotive and engineering (Imaginarium Rapid), and healthcare (Imaginarium Life).

Innovation & USP: Pioneered 3D printing in India’s jewelry industry – the founders brought one of India’s first 3D printers in 1998. It operates 20+ industrial printers producing ~2,500 parts daily, offering end-to-end product development from design to small-batch production.

Estimated 2026 Revenue: Imaginarium is privately held, but as of 2017 it reached ₹50 Crore revenue (with a 250-member team) and has since grown to be India’s largest 3D printing firm (likely well above ₹100 Cr by mid-2020s).

Funding: No major external funding disclosed (growth driven by internal accruals).

Major Clients/Partners: Over 5,000 jewelry clients and 2,000 industrial clients by 2017 – including Tata Motors, Godrej, L&T, Hero MotoCorp – plus hospitals for custom prosthetics and implants.

Notable Achievements: First Indian 3D printing bureau to serve multiple industries at scale; certified as HP’s first 3D printing partner in Asia-Pacific (having acquired HP Jet Fusion early). It also launched initiatives like Imaginarium Academy (education) and Imaginarium Ventures (investing in 3D printing startups) to spur industry growth.

Strategic Vision: Imaginarium aims to remain the “factory in the cloud” for designers and manufacturers – enabling inventory-free, on-demand production via its online platforms. It continues to adopt new technologies (e.g. first in India with advanced HP Multi Jet Fusion printers) and to expand 3D printing’s applications across fashion, engineering, and medical domains, cementing its role as a leader in India’s additive manufacturing revolution.

2. WOL3D (Mumbai)

Founded: 2016 by Rahul Chandalia (CEO), Pradeep Jain (CTO), Saloni Chandalia (CFO), and Swati Jain.

Core Technologies: A direct-to-consumer 3D printing brand offering affordable FFF 3D printers (via OEM partners), 3D pens, scanners, filaments, and in-house prototyping services. It operates five verticals – hardware sales, print materials, print services, education/training, and end-use product manufacturing.

Key Sectors: Education (trained students in 7,000+ schools via Atal Tinkering Labs and courses), consumer hobbyists and makers, as well as enterprise and government (clients include ISRO, DRDO, various IITs, and corporates like Infosys, Reliance, and JSW).

Innovation & USP: Pioneered the experience-center model for 3D printing – setting up hands-on 3D printing stores in 9+ cities to demystify the tech for the masses. WOL3D provides an entire ecosystem under one brand, from hardware to training and even AMC support, making 3D printing accessible and user-friendly. It has also forayed into 3D printed consumer products (launching a toy line “Vinglits” in 2025) to drive mainstream adoption.

2026 Estimated Revenue: ~₹50–60 Crore (FY2025 was ₹48 Cr with ₹5.5 Cr profit), marking it as one of the fastest-growing 3D printing startups by revenue.

Total Funding: Raised ₹25 Crore in 2024 via an SME IPO (making it India’s first publicly-listed 3D printing company). Previously bootstrapped with ₹4.5 Cr from the founders until the IPO.

Major Partnerships/Clients: Sells through retail chains like Reliance Digital and e-commerce (Amazon, Flipkart). Notable clients include government agencies (for example, DRDO uses WOL3D printers for prototyping drones and robots in-house).

Notable Achievements: Featured on Shark Tank India Season 2, and built India’s largest 3D printer farm (BRAHMA facility) in 2025 to scale production. WOL3D has effectively “democratized” 3D printing in India by selling 1,000+ printers monthly (vs. competitors’ ~10/month) and emphasizing affordability (printers from ₹15,000).

Strategic Vision: To make “WOL3D” synonymous with 3D printing in India – akin to how Bisleri means bottled water. The startup plans aggressive expansion (one experience center in every state, and overseas market entry via Amazon US/UAE) while nurturing a community of young innovators through training, ensuring 3D printing becomes an everyday tool for creativity and manufacturing.

3. Pandorum Technologies (Bengaluru)

Founded: 2011 by Arun Chandru and Dr. Tuhin Bhowmick (along with other young scientists from IISc Bangalore).

Core Technologies: Bioprinting – specializing in 3D-printed human tissues for regenerative medicine and drug discovery. Pandorum develops proprietary bio-inks (hydrogels with living cells) and 3D bioprinters to create functional tissue constructs.

Key Sectors: Healthcare and pharmaceutical R&D – their 3D tissues are used for preclinical drug testing, disease modeling, and potentially for future organ transplant therapy.

Innovation & USP: In 2015, Pandorum made history by 3D-printing India’s first artificial human liver tissue. This lab-grown “mini-liver” remains viable for weeks and mimics key liver functions, enabling more reliable drug toxicity testing without using live animals. They have also bioprinted human corneal tissue – a breakthrough for cornea transplantation research. Pandorum’s tissues demonstrate how cutting-edge biotech can come from a startup rather than big pharma.

2026 Estimated Revenue: Minimal commercial revenue (Pandorum is still in R&D stage; it reported ~₹40 Lakh in operating income in FY2020), with value measured in intellectual property and research outcomes rather than sales.

Total Funding: $32.6 million raised as of 2024, including a $10 Mn Series B in 2024 led by existing and new investors. It has also secured grants from government and global biotech forums.

Major Partnerships/Clients: Collaborations with medical institutions and hospitals for research (e.g. Aster CMI Hospital for liver tissue applications). Likely working with pharma companies for using its liver tissues in drug screening (to reduce failure rates in human trials). Also supported by government biotech initiatives (Pandorum emerged from the bio-innovation ecosystem at IISc).

Notable Achievements: Named a Department of Biotechnology “Innovative Startup” and has been covered by Forbes for its pioneering work in tissue engineering. Its co-founders have appeared on global forums to discuss 3D-printed organs. Pandorum’s 3D-printed corneal tissue won it national acclaim as it could address corneal blindness at scale.

Strategic Vision: To advance from printing tiny liver patches to printing whole transplantable organs in the future. Pandorum envisions bio-printed organs (livers, lungs, pancreases, etc.) addressing the acute shortage of donor organs. In the nearer term, its tissue platforms aim to revolutionize drug development – making trials faster, cheaper, and more human-relevant by using “mini-organs on a chip” instead of animal models.

4. Ethereal Machines (Bengaluru)

Founded: 2014 by Kaushik Mudda and Navin Jain.

Core Technologies: Hybrid manufacturing – Ethereal builds multi-axis CNC machines that also integrate additive manufacturing. Its flagship Ethereal Halo was the world’s first affordable 5-axis CNC + 3D printer hybrid, allowing both subtractive and additive processes in one machine. The company continues to develop proprietary 4-axis and 5-axis CNC systems with advanced controllers (increasingly infused with AI for automation).

Key Sectors: Precision manufacturing for aerospace and defense (which contribute ~70% of its revenue), healthcare (custom medical device components), and consumer electronics. Ethereal also serves global clients – about 40% of its projects now are for overseas companies in the US, Europe, Israel, etc., in areas like space tech, drones, and imaging equipment.

Innovation & USP: Ethereal Machines put India on the map by winning the CES 2018 “Best of Innovation” award in 3D Printing – the first Indian company ever to do so. This award recognized the Halo machine, which can manufacture complex geometries with its 5-axis capability, producing stronger parts with fewer support structures compared to conventional 3-axis 3D printers. Ethereal’s machines offer 25–40% faster production and 10–30% cost improvements for customers, by combining processes and leveraging AI-driven optimizations.

2026 Estimated Revenue: Undisclosed, but growing rapidly (the company reported a 4× surge in revenue in 2023 after opening its smart factory). Its focus on high-value B2B orders (aerospace/defense) suggests annual revenues in the tens of crores INR, with profitability driven by in-house part production.

Total Funding: ~$21 million raised. Ethereal secured $7.3 Mn in mid-2023 (via Peak XV’s Surge accelerator and Blume Ventures) and a $13 Mn Series A in 2024 led by Peak XV and Steadview Capital. These funds are fueling R&D (for India’s first homegrown multi-axis CNC controller) and a second smart factory in Bangalore.

Major Partnerships/Clients: No single strategic investor (aside from VCs), but Ethereal partners with various precision engineering firms globally as clients. It has manufactured mission-critical parts for new-space startups, drone manufacturers, medtech companies, and even some Indian defense organizations (given its aerospace focus).

Notable Achievements: Aside from the CES award, Ethereal was part of Peak XV’s Surge cohort as a showcase deep-tech startup. It has developed and launched multiple machines (e.g. the Aura and Nimbus CNC systems in 2023) achieving sub-10 micron precision. The company has demonstrated that Indian hardware startups can compete internationally in advanced manufacturing – its machines now ship to clients abroad, marking a “Make in India” success in a domain long dominated by US, European, and Japanese players.

Strategic Vision: To establish India as a global hub for precision manufacturing and automation. Ethereal is integrating AI into its controllers to enable smart factories that require minimal human intervention. In the next few years, it plans to deliver fully automated multi-axis machines that can fabricate complex, end-use components for aircraft, satellites, medical implants, etc., thereby reducing reliance on imports. Ethereal’s broader vision is to blur the line between 3D printing and CNC machining – providing manufacturers with turnkey systems that can “print and mill” complex parts in one go, drastically compressing production cycles.

5. Intech Additive Solutions (Bengaluru)

Founded: 2012 by Sridhar Balaram, originally as Intech DMLS (India’s first metal 3D printing service bureau).

Core Technologies: Metal Additive Manufacturing – Intech designs and builds Direct Metal Laser Sintering (DMLS/SLM) machines. Its iFusion series printers (launched 2020) come in small-format (SF1, for R&D labs) and large-format multi-laser (LFMulti, for industrial production) configurations. Intech also developed its own software suite (AMOptoMet for process optimization and AMBuilder for workflow) to complement the hardware.

Key Sectors: Aerospace, defense, automotive, and medical implants – any industry requiring high-performance metal parts. The company’s service origins mean it also provides end-to-end solutions, from design for AM to final part production, catering to both prototyping and serial production needs.

Innovation & USP: Intech was a pioneer of metal 3D printing in India, being noted in the Wohlers Report 2015 as the country’s first metal AM service provider. Leveraging this experience, it became one of the few Indian firms to manufacture its own 3D printers. The iFusion printers are designed for high precision and reliability at a lower price-point than imported machines, aiming to make metal AM more accessible domestically. Intech’s proprietary parameter optimization software (OptoMet) was compelling enough that global machine-tool leader DMG MORI acquired a 30% stake in the company in 2018. This partnership not only validated Intech’s tech know-how, but also gave it access to global markets and advanced research.

2026 Estimated Revenue: Not publicly disclosed (privately held). Intech generates revenue through both capital equipment sales (its printers) and providing metal printing services/parts. Given its growing install base and contracts (including defense and aerospace orders), industry analysts peg its annual revenue in the range of tens of crores INR.

Total Funding: Around $7–8 million in known investment. The key funding event was DMG MORI’s strategic investment (amount undisclosed, but Intech is Series A stage). It may also have grants under government schemes (it has participated in initiatives like iDEX for defense innovation).

Major Partnerships/Clients: Besides DMG MORI, Intech has collaborated with international OEMs (e.g. it was the first Indian user of Additive Industries’ MetalFAB1 system). Clients include HAL and DRDO in aerospace/defense, and various automotive and industrial manufacturers in India using its printers or services. Intech’s subsidiary Poeir Jets even built India’s first heavy-lift hybrid drone, showcasing an internal use-case of its manufacturing capabilities.

Notable Achievements: Successfully transitioned from service provider to product manufacturer – a rarity in AM. It has exported machines to abroad and received awards for innovation in manufacturing. Intech’s presence at global trade shows (Formnext, IMTEX) since 2018 signaled India’s arrival in metal AM tech. It also contributed to India’s defense self-reliance by locally producing complex metal parts (e.g. engine components).

Strategic Vision: To create a full-fledged metal AM ecosystem in India. Intech’s goal is not just to sell printers, but to support them with software, materials, and training – lowering barriers for Indian industries to adopt 3D printing. It aligns with “Make in India” by reducing dependence on foreign metal printers. Future roadmap likely includes more advanced printers (larger build volumes, multi-material capability) and catering to serial production (by improving speed and automation). Intech also aims to continue its global partnerships, possibly developing specialized machines (e.g., for specific alloys or applications) in collaboration with industry leaders, cementing its role as a global player in metal additive manufacturing.

6. Tvasta Manufacturing Solutions (Chennai)

Founded: 2016 by IIT Madras alumni – Adithya V. S., Vidyashankar V., and Parivartan Jain – as a construction-tech startup focused on 3D printing buildings.

Core Technologies: Concrete 3D Printing – Tvasta has developed large-format 3D printers and proprietary concrete mixes that allow automated printing of full-scale structures. Its technology integrates robotics and material science to rapidly print building components layer-by-layer (also known as additive construction).

Key Sectors: Housing and infrastructure – particularly low-cost housing, disaster-relief shelters, and military or remote site construction. Tvasta’s 3D printing can produce walls and modular structures faster and with less waste than traditional construction, targeting the affordable housing shortage in India. They have also engaged in projects for offices and amenities buildings.

Innovation & USP: Tvasta is a pioneer of 3D printed construction in India. In 2020, it built India’s first 3D-printed house (a single-story home) on the IIT-Madras campus, showcasing the feasibility of this tech. By 2023, it printed India’s first 3D-printed public building – a prototyping lab office in Bangalore – and a 3D-printed post office. The startup’s printing tech can complete a 1-bedroom house in just a few weeks, using specially-formulated concrete that sets quickly. This speed and cost-efficiency (20–30% cost savings vs conventional methods) has drawn nationwide attention.

2026 Estimated Revenue: Still in project-based early revenue stage. It has begun earning from pilot projects with governments and firms (for example, printing demo houses for state agencies). Estimates put its 2025 revenue in the low crore range, expected to grow as 3D-printed buildings gain regulatory approvals.

Total Funding: Around $0.5–1 million disclosed. Tvasta raised ₹3 Crore ( ~$411k) seed investment in 2021 from Habitat for Humanity’s Shelter Venture Fund (after graduating from Habitat’s ShelterTech accelerator), along with additional angel funding (Hestia Partners and Capnetic Investments). It has also received grants under government innovation programs.

Major Partnerships/Clients: Key partner: Habitat for Humanity International, which not only funded Tvasta but is helping deploy its technology for affordable housing. Tvasta collaborated with the Military Engineering Services to showcase defense applications (like barrack bunkers), and with state governments (e.g. Telangana and Kerala’s housing boards) to pilot 3D-printed homes. Notably, Godrej Construction partnered with Tvasta to 3D-print a pavilion in Mumbai in 2023, indicating interest from large construction firms.

Notable Achievements: In 2020, Tvasta unveiled a 600 sq.ft. 3D-printed house (within IIT Madras), one of the first in the Asia-Pacific region. By 2022, it delivered a 3D-printed prototype military bunker for the Indian Air Force. In 2023, it printed a two-storied 3D-printed office building for a research institute – a milestone proving multi-story capability. The startup has been covered by international media as trailblazing “Concrete Printing” in India, and was invited by the Indian government to contribute to formulating a national strategy on 3D printing in construction.

Strategic Vision: To scale up 3D-printed housing across India and solve the subcontinent’s massive housing shortfall with sustainable technology. Tvasta’s roadmap involves developing larger and faster printers that can be deployed on construction sites, and working with policymakers to update building codes for 3D-printed structures. By 2026, it aims to move from demonstration projects to full-fledged commercial housing developments. Ultimately, Tvasta envisions an “automated construction” paradigm where buildings are custom-designed digitally and robotically printed on-site, reducing labor needs and construction time significantly, while using locally sourced materials to promote sustainability.

7. Fabheads Automation (Chennai)

Founded: 2015 by Dhinesh Kanagaraj and Abhijeet Rathore, former ISRO engineers.

Core Technologies: Continuous Fiber 3D Printing & Composite Automation – Fabheads has developed patented processes (like Adaptive Toe Placement) for 3D printing with carbon fiber and other composites. Their custom 3D printers can lay continuous fiber reinforcements, producing parts that are both lightweight and extremely strong (much superior to standard plastic prints). They also build automated fiber-laying machines and provide end-to-end composite fabrication services.

Key Sectors: Aerospace and defense (for drone airframes, satellite components), mobility/automotive (lightweight parts), and renewable energy (e.g. composite turbine components). Fabheads also serves robotics and marine (shipping) sectors requiring high-performance composite parts. Clients include Tata Advanced Systems, ISRO, and the Motherson automotive group.

Innovation & USP: Fabheads is a pioneer in composite 3D printing in India. While traditional composites manufacturing is manual and labor-intensive, Fabheads introduced automation: its in-house developed technology can precisely deposit continuous carbon fiber in complex shapes, reducing manual work and avoiding the brittleness issues of composites. This innovation won Fabheads recognition because continuous fiber prints combine the design freedom of 3D printing with the superior strength-to-weight ratio of composites – enabling, for example, drone frames or aircraft components that are far lighter yet strong. Fabheads’ adaptive fiber placement technique is unique in handling the tricky behavior of fibers (preventing breakage while printing tight radii).

2026 Estimated Revenue: Not publicly reported. Fabheads generates revenue through machinery sales and on-demand production of composite parts. It remained a small enterprise for initial years but post-2023 expansion, its revenues are expected to scale into the ₹10–30 Cr range as it fulfills orders for aerospace and defense clients.

Total Funding: $13 million total raised. It closed a $10 Mn round in mid-2025 led by Accel (with $2.3 Mn of that as venture debt from Trifecta), on top of earlier seed rounds (~$3 Mn). Funding is being used to set up a large new 80,000 sq.ft. factory in Bangalore’s Aerospace Park for mass production of composite parts.

Major Partnerships/Clients: Fabheads has strong links with India’s aerospace entities – working with ISRO on space-grade parts and with HAL/NAL on UAV components. It also partners with drone startups (providing lightweight frames) and has done projects for the Indian Army (portable composite structures). On the sales side, it’s in discussions to supply its continuous-fiber printers to foreign aerospace companies looking to localize in India.

Notable Achievements: Winner of the National Startup Award (2021) in the “Industry 4.0” category for its work in automated manufacturing. Fabheads’ technology attracted marquee investors (Accel) and it was featured by MIT Technology Review India as an innovative startup to watch. The startup has already delivered thousands of 3D-printed composite parts – by 2025 it reported 800+ parts printed during R&D for various industries. It counts several DRDO labs and the Indian Air Force among its clientele for custom components.

Strategic Vision: To industrialize composite manufacturing – Fabheads wants to make composite part production as scalable and automated as metal machining. Its roadmap includes developing bigger and faster multi-axis composite printers, and using machine learning to optimize fiber paths for maximum strength. The new Bengaluru facility will allow it to take on large-volume orders (e.g. hundreds of drone units or automotive parts) which was not feasible earlier. In the long run, Fabheads could become a key supplier of critical composite parts for India’s defense and aerospace needs, and export its machines globally as interest in continuous-fiber 3D printing grows.

8. Divide By Zero Technologies (Navi Mumbai, Maharashtra)

Founded: 2013 by Swapnil Sansare (an electronics engineer turned entrepreneur).

Core Technologies: Industrial FFF 3D Printers – Divide By Zero (DBZ) designs and manufactures a range of Fused Filament Fabrication 3D printers known for their reliability and large build sizes. Key models include the Accucraft i250, Aion 500, Aeqon 400 and the new Quantum series. DBZ’s signature innovation is its patented AFPM (Advanced Fusion Plastic Modeling) technology, which improves on standard FFF by enabling better layer adhesion and consistent extrusion, resulting in stronger, industrial-grade parts.

Key Sectors: Small and mid-size manufacturing enterprises, product design firms, and educational institutions across India. DBZ’s affordable yet robust machines are used in automotive component prototyping, consumer product development, and even by defense labs for quick in-house part fabrication.

Innovation & USP: DBZ’s mission is to “Make in India” 3D printers that are affordable without sacrificing quality. In an industry once dominated by imported printers, DBZ emerged as an Indian OEM providing local support and customizations for Indian users. The AFPM technology is a unique selling point – it tackles common FFF issues (like inconsistent layering) and allows DBZ printers to run reliably 24/7 on shop floors. The company also introduced features like automatic bed leveling and filament sensing early, tailoring its machines for ease of use by professionals. During the COVID-19 pandemic, DBZ printers were extensively used in India to manufacture PPE components, showcasing their reliability at scale.

2026 Estimated Revenue: Not disclosed; however, DBZ has historically been bootstrapped with zero external funding and sustained by sales. It has sold hundreds of units across India (a notable achievement in a nascent market). Annual revenues are likely in the few crores INR, growing steadily as adoption of 3D printing rises in the SME segment.

Total Funding: No significant VC funding – grown organically. (The company did benefit from government grants such as the NIDHI Prayas scheme in its early days and has leveraged institutes for R&D partnerships, but no equity funding rounds are known.)

Major Partnerships/Clients: DBZ has partnered with materials companies to test new filaments on its machines, and with educational initiatives to set up 3D printing labs. Clients include automotive suppliers, electronics casing manufacturers, and reputed organizations like Mahindra & Mahindra (which deployed DBZ printers in innovation labs). In 2023, DBZ partnered with drone startup Zuppa to create mobile “drone factories” – rugged 3D printer units that can be dispatched to print drone parts on demand in remote locations.

Notable Achievements: Recognized by Manufacturing Today magazine as one of India’s top emerging manufacturing startups (2018). DBZ’s Quantum printer (launched in 2022) won the Best Innovation Award at the Mumbai Tech Exhibition for its fully automatic operation and large-scale printing capability. The founder, Swapnil Sansare, is a prominent advocate for homegrown hardware and was honored in Forbes Asia’s 30 Under 30 (Manufacturing & Energy category).

Strategic Vision: To democratize industrial 3D printing in India. DBZ envisions a 3D printer in every engineering office – and to that end, it focuses on lowering cost barriers and providing local service support, which is crucial for wider adoption. Future plans include integrating advanced materials (like carbon-fiber reinforced plastics) into FFF and developing even larger format printers for factory use. The company is also exploring hybrid machines (3D printing + CNC) and automated print farms. By 2026, DBZ aims to be the leading supplier of professional 3D printers in India, empowering thousands of Indian businesses to prototype and produce locally, thereby shortening development cycles and fostering innovation.

9. Objectify Technologies (Noida/Kanpur)

Founded: 2013 by Ankit Sahu at IIT Kanpur’s incubation center (Startup Incubation & Innovation Centre).

Core Technologies: Additive Manufacturing Services – Objectify is one of India’s premier 3D printing service bureaus, offering both metal and polymer 3D printing under one roof. It has capabilities in technologies like SLS, SLA, FDM for polymers and SLM/DMLS for metals, plus complementary services in 3D scanning, reverse engineering, and post-processing.

Key Sectors: Aerospace and defence (for functional metal prototypes and lightweight components), automotive (rapid prototyping and tooling), and industrial machinery (spare parts on-demand). It also serves consumer product startups for prototyping and makes medical device prototypes.

Innovation & USP: As one of the earliest entrants in 3D printing services in India, Objectify built expertise in delivering end-use quality parts. It distinguishes itself by being materials-agnostic – capable of printing in engineering plastics, resins, and a variety of metals (aluminum, titanium, Inconel, etc.). Notably, Objectify was among the first in India to offer metal 3D printing services to the public, filling a critical gap for industries and the military which needed local rapid manufacturing of complex metal parts. It has since delivered 3D-printed rocket and missile components, satellite parts, and automotive engine parts that perform under real conditions.

2026 Estimated Revenue: Not publicly disclosed. Objectify has grown via project-based revenue; by mid-2010s it was serving dozens of clients and generating a few crore INR annually. With the boom in demand for aerospace 3D printing (e.g. for engine component prototyping) in recent years, its revenue likely climbed into the ₹10–20 Cr range, making it a self-sustaining venture (it reached seed-stage profitability early on).

Total Funding: Seed-funded – initial support came from IIT Kanpur and possibly government grants. No large VC rounds have been reported, implying Objectify scaled largely through reinvesting earnings. In 2020, it was in talks for strategic partnerships rather than pure funding.

Major Partnerships/Clients: Objectify has an impressive client roster: it has executed projects for ISRO (space-grade parts), HAL and DRDO (defense components), Indian Air Force (spare parts for legacy aircraft), and global OEMs like Boeing and Honeywell for prototyping. It partnered with premium automotive firms to print custom tooling and with medical researchers to print patient-specific implants. It also collaborated with academia (IITs) on materials research for AM.

Notable Achievements: Objectify was highlighted by YourStory and others as a startup “making inroads” in manufacturing early on. It won the “National Entrepreneurship Award 2017” in the Manufacturing category. In 2018, it was the first in India to install certain advanced metal printers (like the EOS M400 system), giving domestic firms local access to state-of-the-art equipment. The startup has also obtained AS9100 certification for aerospace quality management, underlining the maturity of its processes.

Strategic Vision: To evolve into a one-stop advanced manufacturing solution for South Asia. Objectify’s roadmap involves expanding capacity (more machines including HP MultiJet and Multi-Laser metal systems) and moving towards bridge manufacturing, where they not only make prototypes but also small-batch production for end-use. It plans to deepen expertise in aerospace and medical domains – for example, by developing validated processes for flight-worthy parts and FDA-approved implants. Objectify also envisions partnering or merging with global service networks, positioning India as a cost-effective hub for 3D printed production for overseas clients. By 2026, it aims to be at the forefront of India’s push into high-end manufacturing, complementing traditional factories with agile, tool-less production from digital designs.

10. Fracktal Works (Bengaluru)

Founded: 2014 by Vijay Raghav Varada and Rohit Asil while they were students at Manipal Institute of Technology.

Core Technologies: Desktop and Industrial 3D Printers, SLS technology – Fracktal began with its flagship Julia series of desktop FFF 3D printers, known for their user-friendly design and affordability. Over the years, it expanded into professional printers (the Julia Pro and Julia Extended for larger volumes) and, most recently, collaborated with IISc to develop an indigenous SLS (Selective Laser Sintering) 3D printer called the Apollo 350. Fracktal also offers cloud printing software and runs a 3D printing service for clients without their own machines.

Key Sectors: Initially makers and educational institutions (for desktop printers), now increasingly industrial clients for functional prototyping. Its printers and services are used in consumer electronics prototyping, by design studios, and in automotive supplier R&D. With the Apollo SLS, Fracktal targets automotive and aerospace companies that need high-quality nylon parts.

Innovation & USP: Fracktal was one of the first Indian startups to design 3D printers from the ground up – its Julia printer (launched mid-2010s) incorporated locally sourced components and custom firmware, allowing it to offer a capable 3D printer at a fraction of imported costs. The company emphasizes design aesthetics and ease-of-use; for example, the Julia printer had a sleek form factor and touchscreen interface that stood out in the market.

Fracktal’s recent leap into SLS technology (in partnership with IISc’s FSID) is a significant innovation because SLS printers were previously all imported; Apollo 350 is among the first high-end polymer laser sintering machines developed in India. This opens opportunities to produce durable, complex parts (like lattice structures, functional prototypes) domestically without expensive foreign equipment.

2026 Estimated Revenue: Fracktal secured a sizeable seed funding in 2015 (~$3 Mn) which supported its growth. It has sold units to companies and schools, and its service bureau arm brings recurring income. By 2025, with enterprise orders (including government purchases of Apollo), annual revenue is estimated in the ₹5–10 Cr range. The business is on a path to profitability through hardware sales and printing contracts.

Total Funding: $3.0 Mn raised in 2015 from 1 Neoteric (a tech investor subsidiary of Neoteric Infomatique), and additional undisclosed angel funding from investors like Aarin Capital (Mohandas Pai) in subsequent years. Fracktal has not yet taken Series A VC money, focusing on product development with grant support (the Apollo project was under a government scheme via IISc).

Major Partnerships/Clients: Early on, Fracktal was incubated by MUTBI at Manipal and supported by Hyderabad Angels. Its client list quickly grew to include Cisco, Larsen & Toubro, and Toshiba who used Fracktal’s printers for rapid prototyping needs. It has also supplied 3D printers or services to OEMs like Maruti Suzuki and TVS Motors for design validation. The partnership with IISc (FSID) for developing Apollo 350 SLS is a major collaboration, backed by India’s Ministry of Heavy Industries. Fracktal’s printers have been adopted by several universities and training centers, and it worked with the Indian Army to trial 3D printing parts on-site in Leh (high altitude conditions).

Notable Achievements: Fracktal’s Julia printer won the Best Desktop 3D Printer Award at the 2015 Maker Faire Bangalore. The startup made headlines as a college dorm project turned business, with the founders featured in Forbes India 30 Under 30 (2016) for hardware innovation. By securing marquee customers like L&T early, it proved credibility. In 2021, Fracktal was selected by Airbus’s accelerator (BizLab) to explore aerospace applications. And in 2025, the launch of Apollo 350 at IMTEX was inaugurated by India’s Heavy Industries Minister – underscoring its significance for India’s AM capabilities.

Strategic Vision: Fracktal Works aims to “Make 3D Printing Plug-and-Play” for industry – providing machines that require minimal setup yet deliver professional results. Its future roadmap includes scaling up production capacity (setting up an assembly line for printers), refining its SLS technology for commercialization, and possibly venturing into metal printers in the long term.

The company also plans to develop an ecosystem around its hardware: cloud platforms for print file handling, and materials collaborations to offer a range of certified printing powders/filaments. By 2026, Fracktal envisions being a holistic provider of 3D printing solutions, enabling Indian businesses – big and small – to turn ideas into tangible products rapidly, without dependence on foreign tech. The Apollo SLS project in particular is poised to “transform polymer 3D printing in India” by making high-end manufacturing more accessible and reducing reliance on imported systems.