Top 10 EV Battery Management Systems In 2026

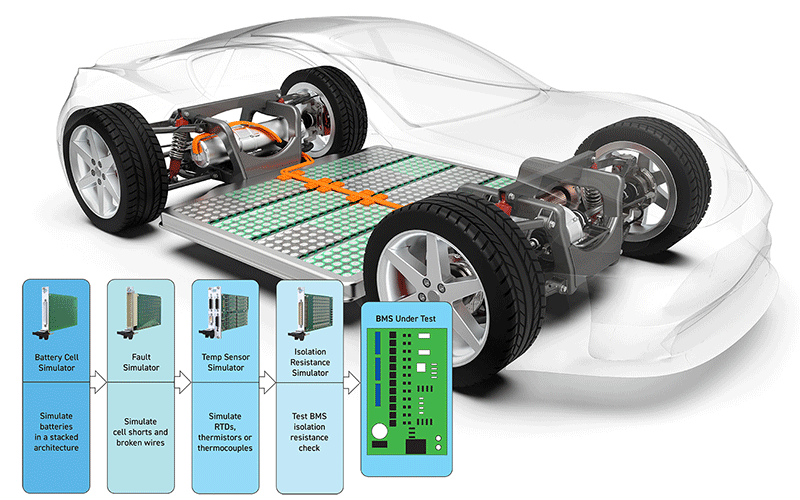

Understanding Battery Management Systems: The Brain Behind Electric Mobility

When you climb into an electric vehicle and press the accelerator, you might marvel at the silent power delivery and smooth acceleration that characterizes electric mobility. What you probably don’t think about in that moment is the sophisticated electronic brain working behind the scenes to ensure that every electron flowing through your battery does so safely, efficiently, and in a way that maximizes the life of your battery pack. This electronic guardian is called a Battery Management System, and it represents one of the most critical technologies enabling India’s electric vehicle revolution in 2026.

1. Maxwell Energy Systems (Endurance Technologies)

Maxwell Energy Systems represents one of India’s most significant Battery Management System success stories. Originally founded as the hardware division of Ion Energy, a Mumbai-based energy technology startup, Maxwell developed deep expertise in designing and manufacturing BMS solutions specifically adapted to Indian and international operating conditions. In 2022, recognizing Maxwell’s potential and the strategic importance of BMS technology in the evolving electric vehicle ecosystem, Endurance Technologies acquired the company in a forty-million-dollar all-cash transaction that brought together Maxwell’s technical capabilities with Endurance’s manufacturing scale and automotive industry relationships.

Today, Maxwell supplies Battery Management Systems to over seventy automotive original equipment manufacturers and battery pack manufacturers spread across fifteen countries including India, France, Spain, and the United States. The company has deployed more than sixty-five thousand smart BMS units in electric vehicles and stationary energy storage systems, accumulating real-world operational data that informs continuous product improvements. This extensive deployment experience gives Maxwell engineers invaluable insights into how batteries perform across different climates, use cases, and vehicle types.

Maxwell’s product portfolio addresses diverse market segments with solutions tailored to specific applications. For two-wheelers and three-wheelers, which represent the largest volume electric vehicle segments in India, Maxwell offers compact monolithic BMS designs optimized for cost-competitive mobility applications where space and weight constraints are paramount. For commercial vehicles and industrial applications like electric forklifts, excavators, and mining equipment, the company provides functionally safe BMS capable of managing high-power, low-voltage battery systems with the robust architecture these demanding applications require.

What distinguishes Maxwell’s approach is its emphasis on creating an ecosystem around the BMS hardware. The company’s solutions include not just the electronic control units that manage individual battery packs, but also master BMS systems that coordinate multiple battery modules connected in series-parallel configurations to achieve higher voltage and capacity for large vehicles. The ecosystem extends to cloud-based diagnostic capabilities that enable remote monitoring, performance optimization, and predictive maintenance. Fleet operators particularly value these capabilities, which allow them to track the health of dozens or hundreds of vehicles from a central operations center, identifying potential issues before they result in vehicle downtime.

The partnership with Endurance Technologies brings substantial advantages in scaling Maxwell’s operations to meet growing demand. Endurance operates twenty-eight manufacturing plants across India and Europe, giving Maxwell access to established supply chains, quality management systems, and customer relationships that would take years to develop independently. The companies plan to expand Maxwell’s research and development team to more than two hundred fifty engineers, accelerating the development of next-generation BMS platforms incorporating artificial intelligence, advanced diagnostics, and new safety features.

Maxwell’s active order pipeline exceeds nineteen and a half million dollars, reflecting strong customer confidence in the company’s technology and execution capabilities. As Indian and European automakers accelerate their electrification plans, they increasingly view BMS as a key differentiator in battery performance, with particular emphasis on safety, range optimization, and power delivery. Maxwell’s position as a preferred supplier to major OEMs positions it to benefit directly from the anticipated rapid adoption of electric vehicles over the coming years.

2. Lithion Power

Lithion Power stands as India’s largest manufacturer of advanced Battery Management Systems, having focused exclusively on developing control systems for electric vehicles and energy storage batteries since the company’s founding in 2016. This singular focus on BMS technology has enabled Lithion to develop deep expertise and specialized capabilities that generalist electronics manufacturers often lack. The company pioneered several innovations in the Indian market, including being the first BMS manufacturer in India to launch smart BMS products and the first globally to introduce semi-smart BMS architectures that balance functionality with cost-effectiveness.

The company’s flagship Smart BMS product line incorporates sophisticated monitoring, protection, and optimization capabilities wrapped in a package designed for ease of integration into diverse vehicle platforms. These systems continuously track cell voltages, temperatures, and current flow, making real-time decisions about charge acceptance, power delivery, and cell balancing. The BMS communicates with vehicle systems through standard automotive protocols, providing the motor controller, dashboard display, and telematics systems with accurate battery status information.

Lithion Power’s achievement of AIS 156 approval represents a significant milestone in establishing its products’ credibility in the Indian market. The Automotive Industry Standard 156, developed by the Automotive Research Association of India, specifies comprehensive safety requirements for lithium-ion battery systems used in electric vehicles. Compliance with AIS 156 Phase 2 requirements demonstrates that Lithion’s BMS can properly protect batteries against overcharge, over-discharge, short circuits, thermal events, and other fault conditions that could compromise safety. For vehicle manufacturers seeking regulatory approval for their electric models, partnering with an AIS 156-certified BMS supplier streamlines the certification process.

Beyond automotive applications, Lithion Power has expanded its portfolio to serve diverse energy storage needs across multiple sectors. The company provides BMS solutions for point-of-sale machines used in retail operations, ensuring uninterrupted transaction processing even during power fluctuations. Industrial robotics manufacturers rely on Lithion’s BMS to manage the batteries powering automated manufacturing equipment and autonomous mobile robots. The company’s solutions also enable renewable energy storage systems that capture solar or wind energy for later use, helping homes and businesses reduce grid dependence and electricity costs.

Lithion Power’s commitment to innovation extends to developing customized solutions that address specific customer requirements. The company’s engineering team works closely with vehicle manufacturers and battery pack assemblers to optimize BMS configurations for particular applications, adjusting protection parameters, communication protocols, and packaging to match each customer’s unique needs. This flexibility proves particularly valuable in India’s diverse electric vehicle market, where manufacturers produce everything from low-speed electric rickshaws to high-performance electric motorcycles, each with distinct battery management requirements.

The company’s growing client base and expanding product offerings position it as a key enabler of India’s electric mobility transition. As the domestic electric vehicle industry matures and production volumes scale, demand for proven, reliable BMS solutions continues to accelerate. Lithion Power’s established manufacturing capabilities, technical expertise, and track record of innovation position it to capture a substantial share of this expanding market opportunity.

3. Tata AutoComp Systems

Tata AutoComp Systems brings the resources and credibility of the Tata Group to India’s Battery Management System market. As a leading automotive component manufacturer with deep relationships across the Indian automotive industry, Tata AutoComp has leveraged its established position to quickly become a significant player in electric vehicle technologies. The company’s strategy centers on developing integrated solutions that combine battery packs with sophisticated management systems, providing vehicle manufacturers with complete energy storage solutions rather than individual components.

The company’s joint venture partnerships with international technology providers have accelerated its BMS capabilities. By collaborating with companies at the forefront of battery and power electronics technologies, Tata AutoComp gains access to proven designs, manufacturing processes, and technical expertise that would take years to develop independently. These partnerships enable the company to offer BMS solutions that meet global standards for performance, safety, and reliability while adapting them for Indian market requirements and cost structures.

Tata AutoComp’s particular strength lies in its close relationship with Tata Motors, one of India’s largest automotive manufacturers and an increasingly important player in the electric vehicle market. Tata Motors’ electric passenger vehicles including the Nexon EV and Tigor EV have achieved significant commercial success, establishing the company as India’s leading electric car manufacturer by sales volume. The ability to work closely with Tata Motors during vehicle development, understanding their specific requirements and incorporating BMS features that enhance overall vehicle performance, provides Tata AutoComp with invaluable insights and a built-in customer for its products.

The company’s focus on sustainability extends beyond the products themselves to encompass the entire manufacturing process. Tata AutoComp has implemented environmentally responsible manufacturing practices, waste reduction initiatives, and energy efficiency measures across its production facilities. This commitment to sustainability resonates with electric vehicle manufacturers and environmentally conscious consumers who view electric mobility not just as a transportation choice but as part of a broader commitment to environmental stewardship.

Tata AutoComp’s extensive product portfolio spans multiple automotive systems including transmission components, seating systems, plastic components, and electronics. This breadth enables the company to offer integrated solutions that simplify vehicle assembly and reduce the number of suppliers automakers must coordinate with. For electric vehicles, the company can provide not just the BMS but also battery enclosures, thermal management systems, and power distribution components as a comprehensive package.

As the Indian electric vehicle market expands beyond passenger cars into commercial vehicles, buses, and eventually heavy trucks, Tata AutoComp’s established relationships with commercial vehicle manufacturers position it to extend its BMS business into these growing segments. The company’s reputation for quality, reliability, and technical support makes it a trusted partner for manufacturers making the complex transition from conventional powertrains to electric propulsion.

4. Exide Industries

Exide Industries brings nearly a century of battery expertise to the Battery Management System market. Founded in 1947, the company established itself as India’s largest battery manufacturer, building a dominant position in lead-acid batteries for automotive, industrial, and backup power applications. This deep understanding of battery chemistry, manufacturing, and application requirements provides a strong foundation for the company’s expansion into lithium-ion technologies and associated management systems.

The company’s transition from primarily lead-acid battery manufacturing to incorporating advanced lithium-ion solutions reflects the broader transformation occurring across the energy storage industry. Exide has made substantial investments in developing lithium-ion battery manufacturing capabilities through its subsidiary and new production facilities. These investments include technology partnerships with international leaders in battery and BMS technologies, giving Exide access to proven designs and manufacturing processes while maintaining the ability to adapt them for Indian market requirements.

Exide’s extensive dealer network, built over decades serving the automotive replacement battery market, provides a significant distribution advantage as the company expands its electric vehicle battery and BMS offerings. This network reaches into every corner of India, providing service and support infrastructure that many newer entrants to the market lack. For electric vehicle owners concerned about battery service and replacement in the future, Exide’s established presence offers reassurance that support will be available when needed.

The company’s BMS development focuses on creating systems that maximize battery life and performance while ensuring safety across India’s diverse operating conditions. Exide engineers understand from decades of experience how batteries perform in extreme heat, high humidity, dusty environments, and varying power quality conditions. This knowledge informs BMS designs that incorporate appropriate protection thresholds, thermal management strategies, and fault detection algorithms optimized for Indian conditions rather than simply adapting designs developed for European or American markets.

Exide’s participation in India’s electric vehicle ecosystem extends beyond BMS to encompass complete battery pack assembly, energy storage systems for grid applications, and charging infrastructure development. This comprehensive approach positions the company as a total solutions provider capable of addressing multiple aspects of the energy transition. For automakers seeking to reduce supplier complexity, partnering with a company that can provide batteries, BMS, and associated systems from a single source offers significant advantages in coordination, integration, and accountability.

The company’s strong brand recognition and reputation for quality built over seventy-five years in the Indian market provide credibility that emerging BMS manufacturers struggle to match. When vehicle manufacturers and fleet operators evaluate potential BMS suppliers, Exide’s track record and financial stability factor heavily in purchasing decisions, particularly for companies making long-term commitments to electric vehicle platforms that require reliable component supply and technical support over many years.

5. Amara Raja Energy and Mobility

Amara Raja Energy and Mobility, formerly known primarily for its Amaron brand of automotive batteries, has undertaken an aggressive transformation to position itself as a comprehensive energy and mobility solutions provider. The company’s substantial investments in lithium-ion battery technology, gigafactory development, and energy storage systems reflect management’s recognition that the future of energy storage lies in advanced chemistries and integrated electronic management systems rather than traditional lead-acid technologies.

The company’s planned gigafactories represent billion-dollar commitments to building large-scale lithium-ion cell and battery pack manufacturing capacity in India. These facilities will incorporate automated production lines, advanced quality control systems, and integrated BMS assembly capabilities, enabling Amara Raja to control the entire battery production process from cell manufacturing through final pack assembly and testing. This vertical integration provides advantages in cost, quality, and the ability to optimize BMS design in coordination with battery pack architecture.

Amara Raja’s BMS development emphasizes creating intelligent systems that not only protect and optimize battery performance but also provide data and analytics capabilities that enable predictive maintenance and performance optimization over the battery’s lifetime. The company’s systems incorporate telemetry capabilities that transmit battery health data to cloud-based platforms where artificial intelligence algorithms analyze patterns, identify degradation trends, and alert vehicle owners or fleet operators to potential issues before they result in failures or reduced performance.

The company serves both automotive original equipment manufacturers and the replacement battery market, providing solutions for two-wheelers, three-wheelers, passenger vehicles, and commercial vehicles. This broad market coverage enables Amara Raja to develop BMS platforms that can be scaled and adapted across multiple vehicle segments, achieving economies of scale in engineering, manufacturing, and support. The company’s experience serving the demanding replacement battery market, where customers directly experience product quality and reliability, has instilled a strong culture of durability and customer satisfaction that carries forward into its electric vehicle technologies.

Amara Raja’s partnerships with international technology leaders provide access to advanced BMS architectures, semiconductor components, and software algorithms that accelerate product development timelines. Rather than developing every aspect of BMS technology internally, the company strategically partners with specialists in areas like power electronics, embedded software, and cloud platforms, focusing its internal engineering resources on system integration and application-specific optimization.

The company’s commitment to sustainability extends beyond producing technologies that enable electric mobility to encompass responsible manufacturing practices and end-of-life battery management. Amara Raja has developed battery recycling capabilities that recover valuable materials from spent batteries, reducing the environmental impact of battery production and creating a circular economy model that aligns with global sustainability principles.

6. Battrixx (Geon)

Battrixx, which recently rebranded as Geon to reflect its expanded focus on comprehensive green energy solutions, represents an important player in India’s Battery Management System ecosystem. Operating as the future technologies division of Kabra Extrusiontechnik, a listed company, Battrixx benefits from the financial stability and manufacturing expertise of its parent organization while maintaining the agility and innovation focus characteristic of newer technology ventures.

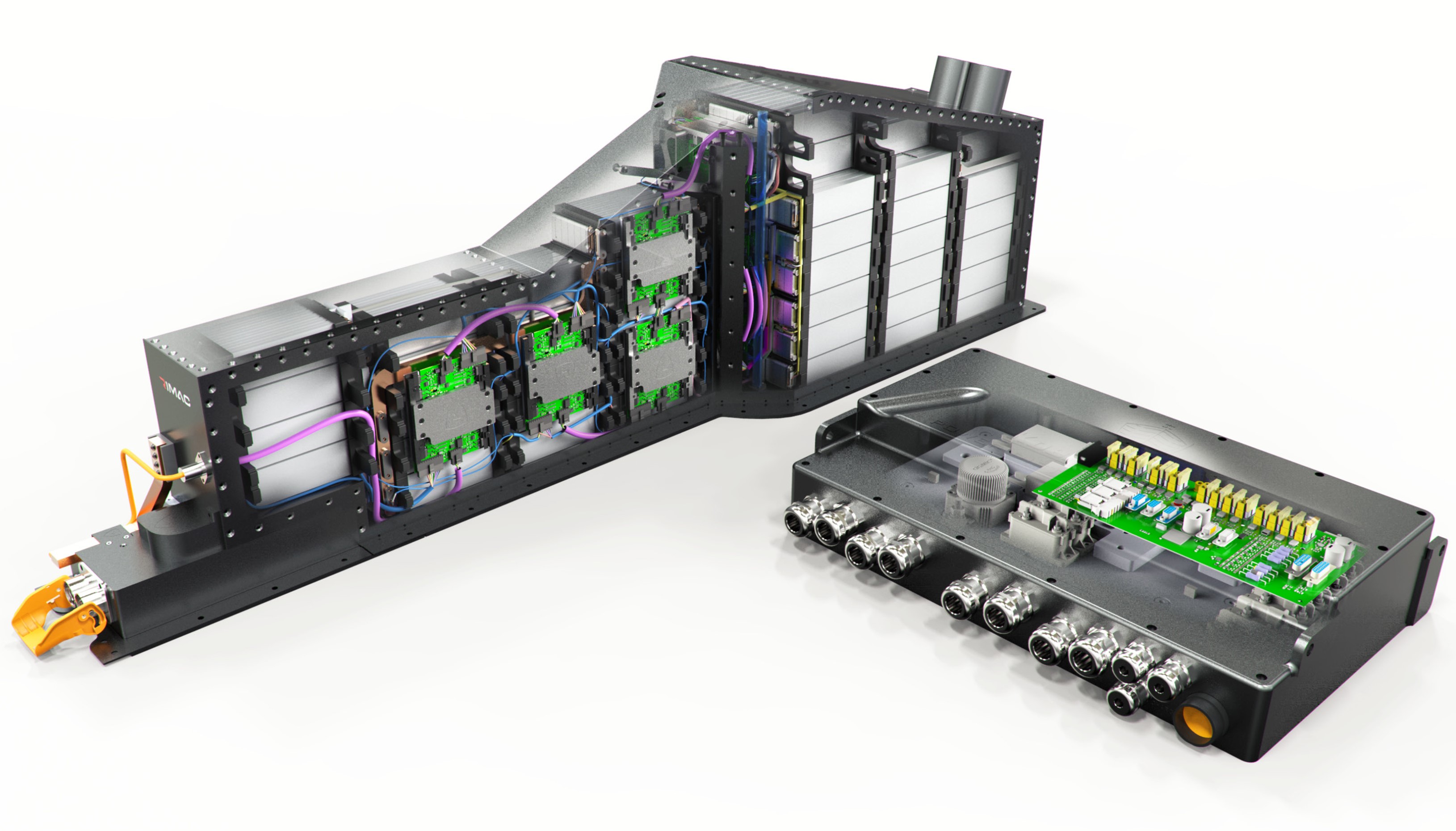

The company specializes in designing and manufacturing lithium-ion battery packs integrated with advanced Battery Management Systems for electric two-wheelers, three-wheelers, and other e-mobility applications. Battrixx’s approach emphasizes creating complete battery solutions rather than selling BMS as standalone components, recognizing that optimal performance requires tight integration between cells, mechanical packaging, thermal management, and electronic controls. This systems-level thinking ensures that every element of the battery pack works harmoniously to deliver maximum range, longevity, and safety.

Battrixx achieved significant validation in 2022 when it became the battery supplier for Hero Electric, one of India’s leading electric two-wheeler manufacturers. This partnership demonstrates the company’s ability to meet the quality, reliability, and production volume requirements of major automotive OEMs. The company’s batteries and BMS systems power thousands of Hero Electric vehicles on Indian roads, accumulating real-world operational data that informs ongoing product improvements and next-generation designs.

The company’s achievement of ARAI certification under AIS 156 Amendment III Phase 2 represents a critical milestone in establishing its technical credibility. The Automotive Research Association of India’s rigorous testing protocols verify that Battrixx’s battery packs and BMS meet comprehensive safety standards covering electrical safety, thermal safety, mechanical safety, and functional safety. For vehicle manufacturers seeking regulatory approval for their electric models, choosing a certified battery supplier simplifies the compliance process and reduces certification risk.

Battrixx’s recent rebranding to Geon and allocation of three hundred crore rupees for expanding manufacturing capacity, including a new facility in Chakan, Pune, signals the company’s ambition to scale significantly beyond its current operations. The new facility will incorporate advanced manufacturing equipment and increased automation, enabling the company to serve growing demand while maintaining consistent quality. The expansion also positions Geon to address multiple green energy segments beyond electric vehicles, including stationary energy storage systems and renewable energy integration applications.

The company’s emphasis on safety, evidenced by its robust BMS protection features and commitment to exceeding regulatory requirements, addresses one of the primary concerns potential electric vehicle buyers express about battery-powered transportation. By incorporating multiple layers of protection against overcharge, over-discharge, short circuits, temperature extremes, and other fault conditions, Battrixx/Geon helps build consumer confidence in electric vehicle safety and reliability.

7. Ion Energy (Altergo Platform)

Ion Energy occupies a unique position in India’s Battery Management System landscape through its focus on software and data analytics platforms that complement hardware BMS solutions. While the company sold its hardware BMS business, Maxwell Energy Systems, to Endurance Technologies, it retained and continues to develop Altergo, a sophisticated software-as-a-service platform for energy storage system management. This strategic decision reflects management’s vision that the future value in battery management increasingly lies in software, analytics, and artificial intelligence rather than purely in hardware manufacturing.

The Altergo platform represents a modern approach to battery asset management that extends well beyond traditional BMS functions. While conventional Battery Management Systems focus on real-time monitoring and protection of individual battery packs, Altergo operates at a fleet level, aggregating data from hundreds or thousands of battery systems to provide comprehensive visibility into energy storage operations. This bird’s-eye view enables fleet operators, battery rental services, and stationary energy storage operators to optimize their entire battery fleet’s performance, identify assets requiring maintenance, and make data-driven decisions about battery procurement, deployment, and retirement.

The platform incorporates machine learning algorithms that analyze patterns in battery usage, charging behavior, temperature exposure, and performance degradation to predict remaining useful life and identify batteries likely to experience issues in the near future. This predictive maintenance capability transforms battery management from reactive problem-solving to proactive optimization, reducing unexpected downtime and enabling more efficient maintenance scheduling. For electric vehicle fleet operators managing hundreds of vehicles, these capabilities can translate to substantial operational cost savings and improved vehicle availability.

Ion Energy’s cloud-based architecture enables continuous software updates and feature additions without requiring hardware changes. As battery chemistries evolve, new optimization algorithms are developed, or customer requirements change, Altergo can adapt through software updates deployed remotely to all connected battery systems. This flexibility contrasts with traditional embedded BMS approaches where functionality is largely fixed at the time of manufacture.

The company’s focus on software and analytics positions it to benefit from several important trends in the energy storage industry. As battery costs decline and deployment volumes increase, the economic value of optimization and life extension grows correspondingly. A one percent improvement in battery life or a five percent increase in usable capacity delivered through better management algorithms can justify substantial software subscription fees when applied across large battery fleets. Similarly, as renewable energy systems scale and grid storage becomes more prevalent, the ability to orchestrate thousands of battery systems to provide grid services creates new revenue opportunities that software platforms enable.

Ion Energy’s partnerships with battery pack manufacturers and BMS hardware providers create an ecosystem where Altergo complements rather than competes with hardware suppliers. This collaborative approach recognizes that optimal battery management requires both capable hardware performing real-time monitoring and protection, and sophisticated software analyzing patterns across time and multiple assets. By focusing on the software layer, Ion Energy avoids competing directly with its hardware partners while providing capabilities they would struggle to develop independently.

8. Exicom Energy Solutions

Exicom Energy Solutions approaches Battery Management Systems from the perspective of integrated energy solutions, combining battery technologies with charging infrastructure, renewable energy systems, and power electronics. This comprehensive approach recognizes that BMS doesn’t operate in isolation but rather as part of a larger energy ecosystem encompassing generation, storage, conversion, and delivery.

The company’s product portfolio includes lithium-ion battery systems and associated BMS designed for electric vehicles across multiple segments including two-wheelers, three-wheelers, passenger cars, and commercial vehicles. Exicom’s BMS solutions incorporate advanced battery analytics platforms that provide detailed insights into battery health, performance trends, and optimization opportunities. These analytics capabilities extend traditional BMS functions, transforming the system from a real-time protection device into a comprehensive battery intelligence platform.

Exicom’s development of battery swapping systems represents an innovative approach to addressing one of electric mobility’s persistent challenges, the time required to recharge batteries. Battery swapping enables electric vehicle drivers to exchange depleted batteries for fully charged ones in minutes rather than waiting for charging to complete. This approach requires sophisticated BMS capabilities to track battery health across multiple charge-discharge cycles, ensure compatibility between batteries and various vehicles, and maintain safety standards when batteries are frequently connected and disconnected.

The company’s expertise in DC fast charging and ultra-fast charging infrastructure complements its BMS business, as effective charging requires close coordination between the charger and BMS to optimize charging speed while protecting battery health. Exicom’s systems communicate bidirectionally, with the BMS informing the charger about battery status, temperature, and acceptable charge rates, while the charger adjusts its output accordingly. This intelligent charging approach maximizes convenience for users while minimizing stress on batteries that could shorten lifespan.

Exicom’s integration of renewable energy with electric vehicle charging and battery storage creates synergies that benefit customers economically and environmentally. Solar-powered charging stations equipped with battery storage enable clean energy to power electric vehicles while reducing grid dependence and electricity costs. The BMS plays a crucial role in these integrated systems, managing energy flows between solar panels, batteries, charging stations, and the grid to optimize performance and economics.

The company’s position as a comprehensive energy solutions provider rather than a single-product manufacturer provides advantages in serving customers with complex needs. Organizations deploying electric vehicle fleets often require charging infrastructure, power distribution upgrades, energy management systems, and potentially battery storage alongside the vehicles themselves. Exicom’s ability to address all these requirements through integrated solutions simplifies procurement, ensures compatibility, and provides a single point of accountability for system performance.

9. Reliance Industries

Reliance Industries, India’s largest private sector company, has made substantial strategic commitments to electric mobility and battery technologies through its New Energy business division. The company’s entry into Battery Management Systems represents part of a broader strategy to establish an integrated presence across the entire electric vehicle value chain, from battery cell manufacturing through vehicle assembly and charging infrastructure.

Reliance’s approach leverages the conglomerate’s enormous financial resources, established relationships with international technology partners, and demonstrated capability to scale new businesses rapidly. The company plans to invest extensively in developing and manufacturing battery cells, battery packs, and associated management systems at facilities being established in Gujarat. These investments include partnerships with leading global battery manufacturers that provide access to proven technologies while enabling Reliance to adapt them for Indian market conditions.

The company’s BMS development focuses on creating systems optimized for integration with Reliance’s own battery cells and packs, ensuring tight coordination between all elements of the energy storage system. This vertically integrated approach enables Reliance to optimize BMS algorithms specifically for the battery chemistry, cell configuration, and thermal management systems it employs, potentially achieving better performance than generic BMS solutions designed to work with diverse battery types.

Reliance’s established presence in telecommunications infrastructure through Jio provides interesting opportunities for leveraging connectivity technologies in battery management. Advanced BMS systems increasingly incorporate cellular connectivity, enabling remote monitoring, over-the-air software updates, and data analytics. Reliance’s telecommunications expertise and infrastructure could enable innovative connected battery management solutions that differentiate its offerings from competitors.

The company’s stated ambition to become a significant player in India’s electric vehicle ecosystem extends beyond supplying components to potentially manufacturing complete vehicles. This vertical integration strategy, if successfully executed, would create substantial internal demand for Reliance’s BMS technologies while also enabling the company to offer these systems to third-party battery pack assemblers and vehicle manufacturers seeking proven solutions.

10. Daly BMS (India Distribution)

Daly BMS products, while originally designed and manufactured in China, have achieved significant presence in the Indian market through an extensive distribution network serving battery pack assemblers, electric vehicle manufacturers, and energy storage system developers. These products represent an important category in India’s BMS ecosystem, providing cost-competitive solutions for applications where established automotive-grade systems might be economically unjustifiable.

Daly’s product portfolio spans a wide range of battery voltages, current capacities, and form factors, enabling battery pack designers to select BMS solutions appropriate for specific applications. The company offers both common port designs where charging and discharging occur through the same terminals, and separate port configurations that enable different connections for charge and discharge paths. This flexibility proves valuable in custom battery applications where space, cost, or specific circuit requirements drive design decisions.

The BMS products incorporate fundamental protection functions including overcharge protection, over-discharge protection, short circuit protection, and temperature monitoring. These core capabilities ensure that batteries operate within safe parameters, preventing the most common failure modes that can damage batteries or create safety hazards. While perhaps lacking some of the advanced features of premium automotive-grade systems like predictive maintenance algorithms or sophisticated cloud connectivity, Daly BMS provides the essential protection necessary for safe battery operation.

Daly products find applications across diverse market segments in India, from electric rickshaws and low-speed electric vehicles where cost pressures are intense, to stationary energy storage systems and industrial battery packs. The company’s BMS solutions support multiple lithium chemistries including lithium iron phosphate, nickel manganese cobalt, and lithium titanate, enabling battery designers to choose chemistries based on application requirements rather than being constrained by BMS compatibility.

The extensive availability of Daly BMS products through distributors and online platforms makes them accessible to small-scale battery pack assemblers, hobbyists, and startups developing innovative electric vehicle concepts. This accessibility democratizes battery technology development, enabling entrepreneurs and small manufacturers to create battery-powered products without requiring the engineering resources to develop proprietary BMS solutions.

While questions about long-term support, software updates, and advanced features may give larger manufacturers pause, Daly BMS serves an important function in India’s electric vehicle ecosystem by providing functional battery protection at price points that enable market entry for cost-sensitive applications. As these applications scale and manufacturers grow, many eventually transition to more sophisticated BMS solutions, but Daly’s products often serve as the starting point that enables initial concept development and market testing.

The Critical Role of BMS in India’s Electric Vehicle Revolution

The Battery Management Systems profiled in this article represent diverse approaches to solving the fundamental challenge of safely and efficiently managing lithium-ion batteries in electric vehicles and energy storage applications. From established industrial conglomerates like Tata and Exide leveraging decades of automotive and battery expertise, to focused technology companies like Maxwell and Lithion Power pioneering advanced BMS architectures, to comprehensive solution providers like Exicom integrating BMS with charging and renewable energy systems, India’s BMS ecosystem reflects the broader dynamism and innovation characterizing the country’s electric mobility transition.

The importance of robust, sophisticated Battery Management Systems extends well beyond the immediate function of protecting individual battery packs. As India works toward its ambitious goals of achieving thirty percent electric vehicle penetration by 2030 and establishing domestic battery manufacturing capabilities to reduce import dependence, the quality and sophistication of BMS technology will significantly influence both consumer adoption and industry competitiveness. Vehicles with superior BMS can offer better range, faster charging, longer battery life, and greater safety, providing compelling advantages that influence purchasing decisions and shape brand reputations.

The Indian government’s emphasis on promoting domestic manufacturing through Production-Linked Incentive schemes and other industrial policies creates opportunities for local BMS manufacturers to scale their operations and compete internationally. Several Indian BMS developers have already achieved exports to European and other international markets, demonstrating that Indian engineering can meet global standards for quality, safety, and performance. As the domestic electric vehicle market grows and Indian manufacturers refine their products through real-world deployment experience, the potential exists for India to emerge not just as a market for BMS technology but as an important global supplier.

The evolution toward increasingly intelligent Battery Management Systems incorporating artificial intelligence, predictive analytics, and cloud connectivity promises to transform these devices from reactive protection systems into proactive optimization platforms. Future BMS will not merely prevent batteries from being damaged but will actively maximize their useful life, optimize charging strategies based on electricity prices and grid conditions, participate in vehicle-to-grid programs that provide grid services, and enable new business models like battery-as-a-service where vehicle owners pay for battery use rather than owning the battery outright.

For consumers considering electric vehicle purchases in 2026, the BMS represents a largely invisible but critically important technology that significantly influences their ownership experience. A sophisticated BMS can mean the difference between a battery that provides consistent performance for ten years and one that degrades noticeably after just three or four years of use. The ability to accurately predict remaining range prevents the anxiety of running out of charge unexpectedly. Optimized charging algorithms reduce the time required to replenish the battery while minimizing stress that accelerates degradation. Thermal management capabilities maintain safe operating temperatures even during India’s brutally hot summers.

The companies profiled in this article are helping to ensure that India’s electric vehicle revolution proceeds on a foundation of safe, reliable, and long-lasting battery systems. Their innovations in hardware, software, and system integration are enabling the transformation from conventional internal combustion vehicles to battery electric mobility, contributing to cleaner air, reduced dependence on imported petroleum, and progress toward India’s climate commitments. As electric vehicles become increasingly mainstream over the coming years, the sophisticated Battery Management Systems these companies develop will continue serving as the invisible guardians ensuring that every journey concludes safely and every battery delivers its full potential.