Top 10 Additive Manufacturing Firms In 2026

Top 10 Additive Manufacturing Firms In 2026: Pioneering the Future of Industrial Production

Additive manufacturing, widely known as three-dimensional printing, has undergone a remarkable transformation from a prototyping curiosity to a cornerstone of modern industrial production. As we progress through 2026, the global additive manufacturing market has reached an estimated value between twenty-five and thirty billion dollars, expanding at a robust annual growth rate exceeding twenty percent. This explosive growth reflects a fundamental shift in how manufacturers approach production, with industries ranging from aerospace to healthcare embracing additive technologies not merely for prototyping but for creating end-use parts that power aircraft engines, replace hip joints, and enable mass customization at scale.

The industry landscape in 2026 is characterized by consolidation, technological maturation, and an expanding application base. Over 2,600 startups and more than 25,000 companies now operate in the additive manufacturing space, supported by 178,650 patents and employing more than 1.3 million professionals globally. North America continues to dominate with nearly thirty-five percent market share, though Asia Pacific emerges as the fastest-growing region with approximately twenty-eight percent of the market. The sector has witnessed significant merger and acquisition activity, with over seven hundred deals reshaping competitive dynamics as established players acquire innovative startups to expand their technological capabilities and market reach.

This comprehensive analysis examines the ten most influential additive manufacturing firms in 2026, selected based on revenue scale, technological innovation, market influence, and strategic positioning. These companies represent the vanguard of an industry that is fundamentally reimagining manufacturing for the digital age.

1. Stratasys: Polymer Printing Pioneer Navigating Market Headwinds

Stratasys stands as one of the most established names in additive manufacturing, with origins tracing back to the invention of fused deposition modeling technology. Based jointly in Minnetonka, Minnesota and Rehovot, Israel, Stratasys specializes in polymer three-dimensional printing solutions that serve aerospace, automotive, consumer products, and healthcare industries. The company’s product portfolio encompasses multiple proprietary technologies including fused deposition modeling, PolyJet multi-material printing, and powder-based systems designed for industrial production environments.

Throughout 2025, Stratasys demonstrated resilience amid challenging macroeconomic conditions characterized by cautious customer capital spending. The company generated quarterly revenues of approximately one hundred thirty-seven million dollars in the third quarter, representing a modest year-over-year decline of just over two percent. Despite system sales headwinds, Stratasys maintained positive operating cash flow through disciplined cost management and strong recurring revenue from consumables and services, which together comprise a substantial portion of total revenue. The company closed the third quarter with two hundred fifty-five million dollars in cash and equivalents with zero debt, providing substantial financial flexibility for strategic investments.

Stratasys secured a one hundred twenty million dollar investment from Fortissimo in early 2025, strengthening its balance sheet to pursue both organic growth and strategic acquisitions. Chief Executive Officer Yoav Zeif has positioned the company as a consolidator in a fragmented market, stating that Stratasys occupies the driver’s seat to capture value creation opportunities as market valuations have become more attractive.

The company’s strategy centers on industrial manufacturing applications where reliability, performance, and long-term support prove critical. Notable 2025 achievements include Toyota’s expansion of Stratasys systems across North American factories for rapid production of custom tools and fixtures, and BOOM Supersonic’s use of Stratasys printers to manufacture over three hundred fifty parts for the XB-1 supersonic aircraft, achieving ninety percent cost and lead time savings compared to conventional manufacturing.

Stratasys launched upgraded systems including the NEO800 Plus and next-generation Fortus 450MC aimed at production-level applications, while introducing P3 Silicone 25A material co-developed with Shin-Etsu for the Origin One platform. These innovations underscore the company’s commitment to expanding materials capabilities and pushing polymer printing into demanding industrial applications. Looking forward, Stratasys faces the challenge of reigniting system sales growth while defending its installed base against emerging competitors, all while pursuing consolidation opportunities in a market where capital constraints have created acquisition targets.

2. 3D Systems: Comprehensive Portfolio Meets Market Transformation

Founded by Chuck Hull, the inventor of stereolithography, in 1986, 3D Systems holds a unique position as one of additive manufacturing’s founding companies. Headquartered in Rock Hill, South Carolina, 3D Systems offers one of the industry’s most comprehensive portfolios spanning hardware, software, materials, and services. The company serves applications from dental restorations and medical devices to aerospace components and jewelry manufacturing, with technology platforms including stereolithography, selective laser sintering, direct metal printing, and multi-material PolyJet systems.

3D Systems has undergone significant strategic evolution in recent years, refocusing on core industrial and healthcare applications while shedding non-strategic businesses. The company emphasizes vertical integration, providing complete solutions rather than standalone hardware, which creates recurring revenue streams through materials, software subscriptions, and services. This business model shift reflects broader industry recognition that sustainable competitive advantage comes from ecosystem lock-in rather than one-time equipment sales.

The company’s materials innovation continues driving adoption in high-value applications. In healthcare, 3D Systems’ biocompatible materials enable production of patient-specific surgical guides, dental aligners, and anatomical models used for pre-surgical planning. The aerospace sector leverages the company’s metal printing capabilities for producing complex, topology-optimized components that reduce weight while maintaining structural integrity. 3D Systems has also invested heavily in software capabilities, recognizing that design-for-additive-manufacturing tools and workflow automation software represent critical enablers for scaling additive production beyond prototyping into serial manufacturing.

While 3D Systems faces intense competition from well-funded rivals, its broad technology portfolio and decades of materials expertise position it as a comprehensive solutions provider capable of addressing diverse customer needs. The company’s challenge in 2026 involves demonstrating that its multi-technology strategy generates superior returns compared to more focused competitors, while accelerating the transition of its installed base from prototyping to production applications where margins and customer lifetime value prove substantially higher.

3. GE Aerospace Colibrium: Industrial Metal Printing at Scale

Operating under the Colibrium Additive brand following rebranding from GE Additive, this division of GE Aerospace represents one of the most significant industrial commitments to metal additive manufacturing. Formed to industrialize additive technologies across General Electric’s global operations, Colibrium has become a dominant force particularly in aerospace and medical manufacturing. The business develops industrial-scale metal printers, metal powders, and comprehensive services while simultaneously using additive manufacturing extensively within GE’s own product lines.

Colibrium’s advantage stems from being both a technology provider and a practitioner. General Electric has consolidated approximately three hundred traditionally manufactured aircraft engine parts into a handful of additively produced components, dramatically improving efficiency and reducing weight in critical applications such as fuel nozzles for the LEAP engine. This internal validation lends tremendous credibility when selling systems and services to external customers. The company offers powder bed fusion systems under the Concept Laser brand and directed energy deposition systems that enable building large parts with high deposition rates.

Annual revenues for Colibrium are estimated at five hundred to six hundred million dollars, making it among the largest pure-play metal additive firms. However, profitability remains elusive, leading to strategic focus on cost-efficient operations and high-margin services including maintenance contracts, training, and engineering consultation. The company has established significant presence in India through partnerships with the Indian Air Force, academic institutions, and local service bureaus, supporting defense and aerospace applications where metal additive manufacturing delivers substantial value.

Colibrium’s materials portfolio encompasses titanium, nickel, aluminum, and cobalt-chrome alloys qualified for demanding applications. The company invests heavily in process development and quality assurance systems necessary for aerospace certification, where statistical process control and part-to-part repeatability prove non-negotiable. As aerospace production rates increase following pandemic recovery, Colibrium is well-positioned to capture both equipment sales and recurring powder revenue from customers adopting metal additive manufacturing for serial production rather than one-off prototypes.

4. EOS GmbH: German Engineering Excellence in Industrial Printing

EOS GmbH, headquartered in Krailling near Munich, Germany, epitomizes precision engineering applied to industrial additive manufacturing. Founded in 1989, EOS pioneered direct metal laser sintering and has built an enviable reputation for reliability and industrial-grade quality. The company specializes in both metal and polymer laser sintering systems serving aerospace, automotive, medical, and tooling applications where performance and consistency cannot be compromised.

EOS systems are renowned for optimization toward high throughput and minimal waste, addressing both economic and sustainability imperatives. The company has installed over five thousand systems globally, with significant penetration in European aerospace and automotive supply chains. EOS takes a holistic approach to additive manufacturing, providing not only hardware but also optimized process parameters, qualified materials, and comprehensive training that enables customers to achieve certified production. This systems-integration mindset differentiates EOS from competitors offering standalone equipment.

The company’s materials portfolio continues expanding to address emerging applications. Recent introductions include specialized nickel alloys for oil and gas applications and anodizable aluminum alloys that combine strength with surface treatment compatibility. EOS has also advanced its polymer capabilities with climate-neutral and carbon-reduced polyamide powders that address growing customer demand for sustainable manufacturing solutions. These materials maintain identical properties to standard offerings, eliminating requalification burdens for existing customers while reducing environmental footprint.

EOS has formed strategic partnerships to expand its ecosystem and market reach. A 2025 alliance with India’s Godrej Enterprises Group aims to develop state-of-the-art additive manufacturing capabilities for Indian aviation and space industries, reflecting EOS’s commitment to high-growth markets. The company also participates actively in industry standardization efforts and has partnered with software providers like Materialise to improve workflow efficiency. EOS faces increasing competition from Asian manufacturers offering lower-cost alternatives, but its focus on quality, repeatability, and customer support continues attracting customers where application risk is high and failure costs are substantial.

5. Desktop Metal: Accessible Metal Printing Through Acquisition

Desktop Metal burst onto the additive manufacturing scene in 2015 with a bold mission to make metal three-dimensional printing accessible and faster. The Massachusetts-based company became known for office-friendly metal printers and high-speed binder jetting technology that promised to democratize metal additive manufacturing beyond specialized service bureaus. Following a celebrated SPAC-driven public listing in 2020, Desktop Metal aggressively acquired companies to expand its portfolio into polymers, dental solutions, and production systems.

The company’s journey took a significant turn in April 2025 when Nano Dimension acquired Desktop Metal, consolidating two publicly traded additive manufacturing firms into a combined entity with expanded technological capabilities. This acquisition reflected broader industry consolidation trends as standalone pure-play additive companies struggled to achieve profitability amid elevated capital costs and lengthened sales cycles. Under Nano Dimension ownership, Desktop Metal’s technologies continue serving customers while benefiting from parent company resources and strategic direction.

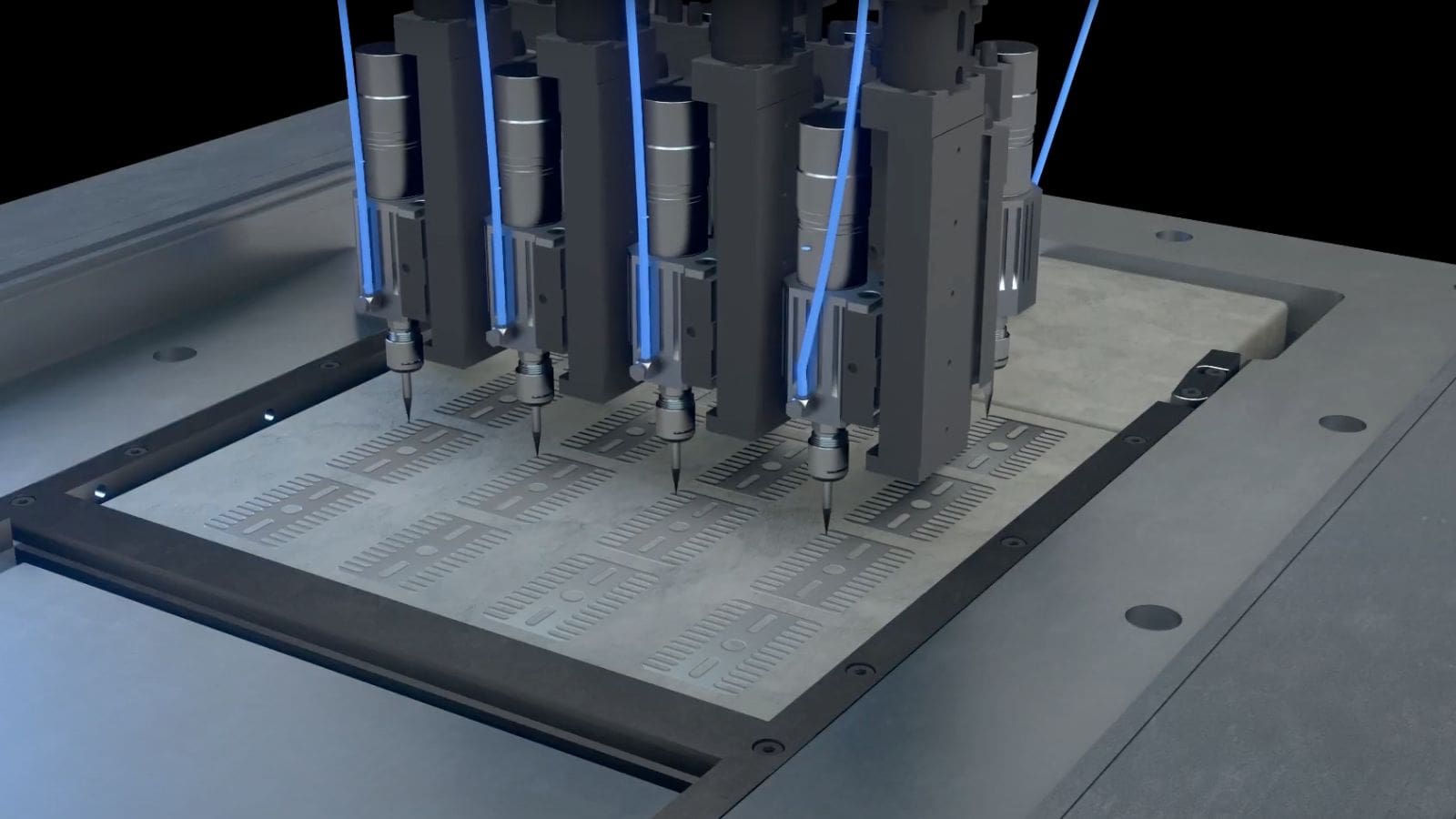

Desktop Metal’s product line centered on two main approaches: binder jetting for high-volume metal production and bound metal deposition for office-friendly metal printing. The binder jetting systems, particularly the Production System and Shop System, use inkjet printheads to selectively bind metal powder layers before sintering, enabling rapid production of complex geometries at costs approaching traditional manufacturing. The bound metal extrusion systems allow engineers to print metal parts using desktop-scale equipment without the safety infrastructure required for powder-bed laser systems.

Despite technological promise, Desktop Metal faced challenges achieving sustainable unit economics. The transition from prototyping systems to production equipment proved difficult as customers demanded extensive application development support, qualified material properties, and long-term reliability data before committing to serial production. The Nano Dimension acquisition provides Desktop Metal with patient capital and complementary technologies in printed electronics, potentially creating new hybrid manufacturing opportunities combining metal structures with embedded functionality.

6. Markforged: Composite Printing for Factory Floors

Markforged has carved a distinctive niche in additive manufacturing by focusing on continuous fiber reinforcement of thermoplastic parts, creating composite materials that approach metal-like properties at polymer prices. Founded to bring industrial-grade composite printing to factory environments, Markforged went public via SPAC in 2021 and generates approximately eighty to one hundred million dollars in annual revenue. While smaller than diversified giants, Markforged has built strong brand recognition in manufacturing circles for reliable, workshop-friendly systems that solve practical production problems.

The company’s core technology, continuous fiber fabrication, represents a genuine innovation in polymer printing. Base thermoplastic materials like nylon or Onyx, a carbon fiber-filled nylon, are printed using standard fused filament fabrication, while simultaneously continuous strands of carbon fiber, Kevlar, or fiberglass are laid into critical load paths within the part. This approach creates anisotropic mechanical properties optimized for specific stress patterns, resulting in parts with exceptional strength-to-weight ratios suitable for tooling, jigs, fixtures, and even some end-use components.

Markforged’s strategy revolves around its Digital Forge platform, encompassing hardware, cloud-based software, and materials that allow manufacturers to fabricate on-demand parts directly on factory floors. This distributed manufacturing model reduces dependence on external suppliers for low-volume custom parts, shortens lead times from weeks to hours, and provides supply chain resilience increasingly valued following pandemic-era disruptions. Applications include manufacturing tooling for assembly lines, custom grippers and fixtures for robotic systems, and spare parts for legacy equipment where traditional sourcing proves difficult.

The company also offers metal printing systems using bound metal deposition technology, though composite systems remain its primary focus. Markforged faces intensifying competition as traditional polymer printer manufacturers add composite capabilities and as customers grow more sophisticated in understanding which applications truly benefit from fiber reinforcement versus standard engineering plastics. The company’s success in 2026 depends on expanding beyond early-adopter manufacturing innovators to capture mainstream factory adoption while defending margins against both premium competitors and low-cost entrants.

7. HP Inc: Multi Jet Fusion Transforms Polymer Production

HP Inc entered additive manufacturing relatively recently but has rapidly established significant market presence through its proprietary Multi Jet Fusion technology. Leveraging decades of inkjet printing expertise, HP developed a polymer powder bed fusion process that achieves production speeds and part costs approaching traditional manufacturing economics for certain applications. This positions HP uniquely among additive manufacturers, as its business model targets true serial production rather than prototyping or limited runs.

Multi Jet Fusion works by depositing fusing and detailing agents across a powder bed using inkjet printheads, then applying thermal energy to selectively fuse material. This approach enables fine feature resolution, complex geometries, and high mechanical properties comparable to injection molding for nylon materials. Critically, HP systems achieve productivity levels that make per-part costs competitive with traditional processes for batch sizes ranging from dozens to thousands of units, opening applications previously uneconomical for additive manufacturing.

HP has pursued a different commercialization strategy than most additive competitors. Rather than selling primarily to end-users, HP works extensively with service bureaus and contract manufacturers who produce parts on behalf of customers. This channel approach accelerates market adoption by leveraging established manufacturing relationships while generating annuity streams from materials sales. HP’s materials come in cartridge form, creating razor-and-blade economics similar to HP’s core office printing business.

Applications for Multi Jet Fusion span automotive interior components, custom orthotics and footwear, consumer electronics housings, and industrial parts. Adidas notably adopted Multi Jet Fusion for mass-customizing midsole lattices in its Futurecraft line. In 2026, HP continues refining materials properties, introducing new polymer chemistries, and developing metal additive capabilities that could extend its technological leadership into higher-value markets. The company’s challenge involves maintaining technology differentiation as patent positions mature and competitors develop similar jetting-based approaches, while expanding from current polymer focus into metal and composite materials where margin opportunities prove more substantial.

8. Velo3D: Pushing Metal Printing Geometry Limits

Velo3D emerged with a focused mission to eliminate geometric limitations in metal additive manufacturing. Founded by Benny Buller, the company developed its Sapphire metal printing systems using proprietary Intelligent Fusion technology that enables printing of complex geometries with minimal or zero support structures. This capability proves transformative for aerospace applications featuring internal channels, overhangs, and lattice structures that traditional powder bed fusion systems struggle to produce reliably.

The Sapphire platform combines advanced recoating systems, real-time process monitoring, and sophisticated software that manages thermal history and residual stress throughout the build. These innovations enable printing of previously impossible geometries while maintaining dimensional accuracy and mechanical properties required for flight-critical components. With eight one-kilowatt lasers in the Sapphire XC variant and large build volumes, Velo3D targets aerospace and defense customers producing structural components where geometric freedom and reduced part count drive significant value.

Velo3D has secured notable aerospace customers including SpaceX, which uses Sapphire systems to produce rocket engine components leveraging intricate internal cooling channels and optimized propellant flow paths unachievable through conventional manufacturing. The company’s Flow software simplifies the design-to-print workflow, automatically generating support structures where absolutely necessary while minimizing their use compared to competitive systems. This reduces post-processing labor and preserves surface finish quality on complex internal features.

Despite technological advantages, Velo3D faces challenges common to capital equipment businesses. Long aerospace certification cycles delay revenue recognition, while profitability remains elusive given high research and development spending relative to current sales volumes. The company has explored strategic options including potential mergers or acquisitions that could provide scale and financial stability. Velo3D’s future depends on converting its geometry-enabling technology into sustained aerospace production wins that drive recurring materials revenue and service contracts, while expanding into adjacent high-value markets like defense and energy where similar geometric requirements exist.

9. Materialise: Software and Medical Applications Pioneer

Materialise occupies a unique position in additive manufacturing as a company centered on software and medical applications rather than hardware sales. Founded in Belgium in 1990, Materialise has become the world’s leading provider of additive manufacturing software while simultaneously operating substantial medical device and service bureau businesses. This diversified model provides Materialise with multiple revenue streams and deep insights into how customers actually use additive technologies in production environments.

Materialise’s software portfolio includes Magics for data preparation and build optimization, which has become industry-standard software used by equipment manufacturers and service bureaus globally. The company’s simulation and lattice generation tools enable engineers to optimize designs for additive production, reducing trial-and-error cycles. Materialise also offers Streamics manufacturing execution system software that provides traceability and quality management for additive production, addressing critical needs as the technology moves into regulated medical device and aerospace applications requiring part genealogy documentation.

In medical applications, Materialise has pioneered patient-specific surgical planning and medical device manufacturing. The company produces FDA-cleared surgical guides, anatomical models for pre-operative planning, and patient-matched implants. Materialise’s software automatically segments medical imaging data and generates printable three-dimensional models that surgeons use to rehearse complex procedures, reducing operating room time and improving outcomes. This high-value medical business generates strong margins and benefits from favorable reimbursement trends as healthcare systems recognize the cost-effectiveness of personalized surgical planning.

Materialise’s service bureau operations provide contract manufacturing for customers across industries, offering access to diverse additive technologies without capital investment. This business generates data on real-world production challenges that feeds back into software development, creating a virtuous cycle of improvement. The company has also developed CO-AM workflow automation software adopted by customers including EOS for internal production efficiency. As additive manufacturing industrializes, Materialise’s software infrastructure becomes increasingly critical, positioning the company to benefit from industry growth regardless of which hardware platforms ultimately dominate specific market segments.

10. Siemens: Digital Manufacturing Ecosystem Leader

Siemens represents a different category of additive manufacturing participant, entering not as a dedicated printer manufacturer but as an industrial automation and digital manufacturing giant incorporating additive into comprehensive production solutions. Through its NX software platform and Additive Manufacturing Network, Siemens enables design-for-additive-manufacturing workflows, digital twin validation, and supply chain collaboration that connects engineering with production. Siemens Energy’s Materials Solutions unit produces certified metal parts for industrial applications, demonstrating the company’s commitment to both enabling and practicing additive manufacturing.

Siemens’ approach emphasizes integration of additive manufacturing into broader Industry 4.0 manufacturing ecosystems. The NX software includes topology optimization, lattice generation, and build simulation tools that allow engineers to exploit additive’s geometric freedom while ensuring manufacturability. Parts can be virtually validated before production, reducing expensive build failures. The Additive Manufacturing Network provides cloud-based collaboration enabling distributed engineering teams to design, simulate, and source additive production globally, supporting resilient supply chains less dependent on centralized manufacturing.

Siemens Energy has qualified numerous additively manufactured components for power generation applications, including gas turbine burners and combustion components that operate for thousands of hours in extreme environments. These references provide compelling validation for industrial customers evaluating additive’s reliability for mission-critical applications. Siemens combines hardware agnosticism with process expertise, helping customers select optimal technologies and parameters for specific applications rather than being locked into single equipment vendors.

The company’s acquisition of Atlas 3D in 2023 expanded its additive software capabilities with specialized tools for managing multi-technology production. Siemens envisions future factories where additive systems seamlessly integrate with traditional CNC machining and other processes, orchestrated through common digital platforms that optimize production based on real-time demand and equipment availability. This hybrid manufacturing vision positions Siemens to benefit as additive transitions from specialized standalone operations to integrated elements of automated production lines, though execution requires overcoming technical integration challenges and convincing conservative manufacturing customers to embrace new workflow paradigms.

Outlook for Additive Manufacturing in 2026 and Beyond

The additive manufacturing industry enters 2026 at an inflection point. Technologies have matured sufficiently that serial production applications proliferate across aerospace, automotive, medical, and industrial markets. Materials portfolios expand continuously with performance approaching traditionally manufactured alternatives. Cost structures for certain applications now compete with injection molding, casting, and machining for production volumes measured in thousands rather than dozens.

However, significant obstacles remain. Many additive systems still require extensive manual intervention for build preparation, post-processing, and quality verification, limiting throughput below rates needed for true mass production. Materials costs per kilogram remain elevated compared to traditional feedstocks, making additive uneconomical for simple geometries producible conventionally. Workforce skills gaps persist as few engineering curricula deeply cover design-for-additive-manufacturing principles, while technicians trained to operate and maintain additive systems remain scarce.

The companies profiled here will play crucial roles navigating these challenges. Established players like Stratasys, 3D Systems, and EOS leverage decades of materials expertise and installed base relationships but must accelerate innovation to defend against emerging competitors. Technology innovators like Velo3D and Markforged push geometric and material boundaries but must achieve profitability demonstrating business model viability. Ecosystem integrators like HP, Siemens, and Materialise position for long-term value capture as additive embeds into mainstream manufacturing, though near-term revenue growth may lag hardware-focused rivals.

For end-users evaluating additive adoption in 2026, the diversity of approaches among leading firms offers opportunities to match technology selection with specific application requirements, risk tolerance, and strategic objectives. Aerospace and medical customers prioritizing absolute reliability and certification support gravitate toward established players with decades of regulatory experience. Manufacturing innovators seeking geometric freedom choose platforms like Velo3D that eliminate design constraints. Cost-sensitive production customers explore HP Multi Jet Fusion’s competitive economics for polymer parts. This market segmentation will persist as additive manufacturing continues diversifying from monolithic “three-dimensional printing” into multiple distinct technology families each optimized for specific materials, geometries, production volumes, and quality requirements.

The twenty-five to thirty billion dollar market in 2026 will likely double again within five years as aerospace production rates increase, automotive electrification creates new part opportunities, medical personalization expands, and supply chain considerations drive local production adoption. The companies commanding premium positions today through technological leadership, materials expertise, customer relationships, and ecosystem integration will capture disproportionate value from this growth, cementing additive manufacturing’s transformation from prototyping novelty to foundational industrial production method.