Top 10 AI in Manufacturing Companies In 2026

Introduction: The AI-Powered Industrial Revolution

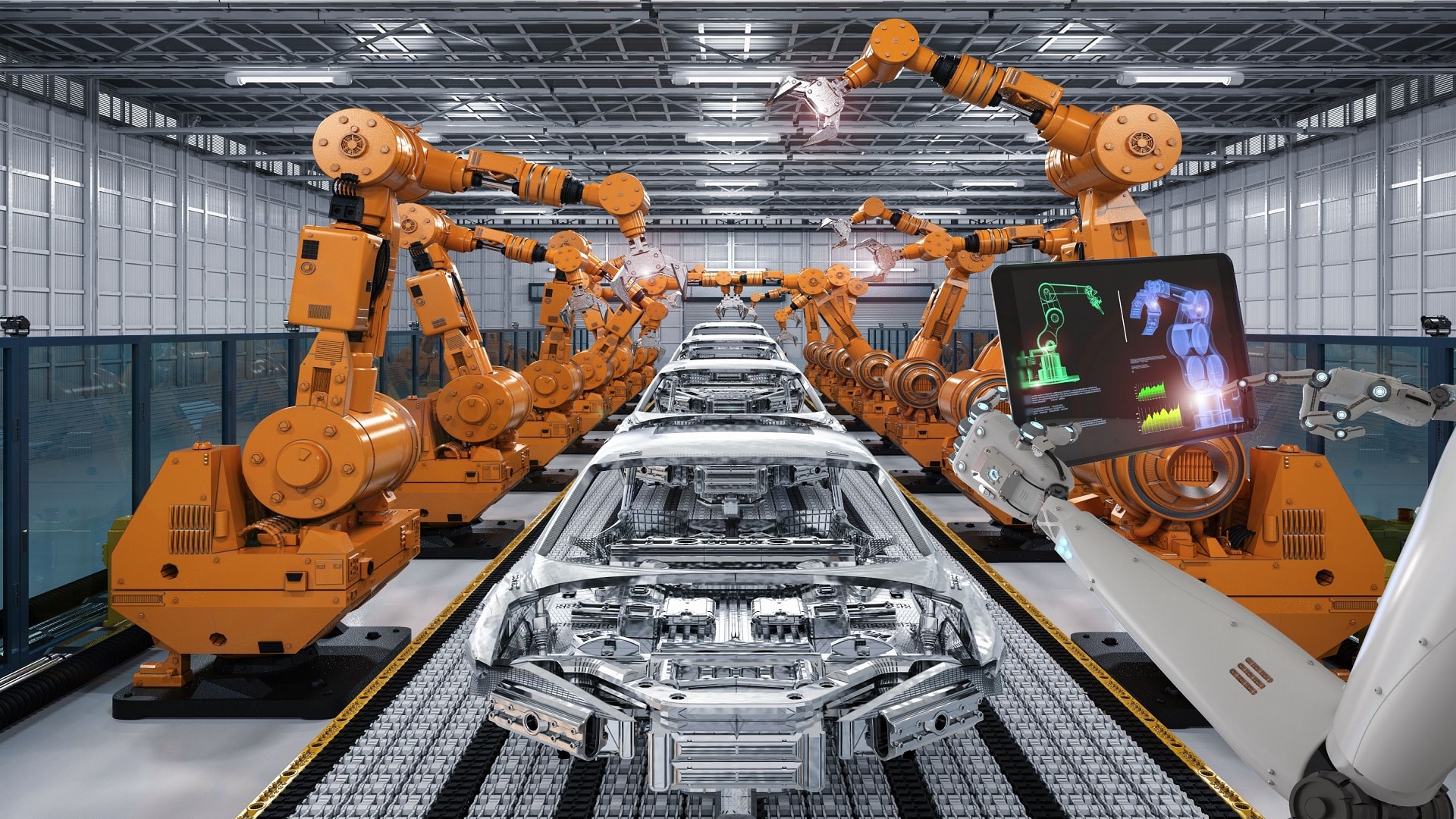

The manufacturing industry stands at the precipice of its most significant transformation since the assembly line revolutionized production over a century ago. Artificial intelligence is not simply improving manufacturing processes—it is fundamentally reimagining what factories can be, how they operate, and what levels of efficiency and autonomy are possible. As we navigate through 2025 and look toward 2026, the integration of AI into manufacturing has moved decisively beyond experimental pilots into mission-critical, production-scale deployments that are reshaping the global industrial landscape.

This comprehensive guide examines the ten most influential companies driving this AI-powered industrial revolution. These are not traditional manufacturers that happen to use AI internally, but rather the technology leaders and solution providers that are building, delivering, and enabling AI capabilities for manufacturers worldwide. Whether you’re a manufacturing executive evaluating AI investments, an engineer seeking to understand the technology landscape, an investor analyzing the industrial AI market, or simply someone interested in how technology is reshaping one of the world’s most foundational industries, this guide provides the depth and context you need to understand where manufacturing intelligence is heading.

The Top 10 AI in Manufacturing Companies for 2026

1. Siemens AG: The Digital Twin Pioneer

Siemens stands as perhaps the most comprehensive player in industrial AI, offering an end-to-end ecosystem that spans from software for designing products and factories to the physical automation equipment that runs them, all unified by AI-powered intelligence. The German technology giant serves manufacturers across virtually every sector, from automotive and aerospace to pharmaceuticals and consumer goods.

The company’s Digital Industries division provides the Siemens Xcelerator platform, which represents a unified approach to industrial digitalization and AI. Xcelerator connects design tools, simulation software, production systems, and real-time operational data into a cohesive digital thread that follows products from initial concept through production and into service life. This integration enables AI to work with complete context rather than operating on isolated data silos.

Siemens’ Industrial Copilot exemplifies the company’s approach to making AI practically useful for manufacturing professionals. Rather than requiring engineers to become AI experts, Industrial Copilot provides a conversational interface where engineers describe what they want in natural language. The system, built on Microsoft’s Azure OpenAI Service, can generate automation code from text descriptions, diagnose faults by analyzing symptoms and system data, suggest optimizations based on historical performance patterns, and create documentation and standard operating procedures automatically.

The partnership between Siemens and NVIDIA, announced and expanded throughout 2025, represents one of the most significant collaborations in industrial AI. This partnership brings NVIDIA’s cutting-edge AI computing capabilities directly into Siemens’ industrial platforms. The Industrial Copilot for Operations, optimized to run on NVIDIA RTX PRO 6000 Blackwell Server Edition GPUs, delivers real-time AI-powered assistance directly to shop floor operators. The system leverages NVIDIA NeMo microservices and AI blueprints to enable capabilities like video search and summarization, turning hours of factory floor video into searchable, analyzable data.

Real-world results demonstrate the partnership’s impact. BMW Group achieved a thirty-times speedup in transient aerodynamics simulations using Siemens’ Simcenter Star-CCM+ software accelerated by NVIDIA Blackwell GPUs, dramatically reducing both simulation time and energy consumption. Audi deployed Siemens’ Industrial AI Suite in its car body shops, where five million welds are made daily, achieving up to twenty-five times faster inference for AI-driven weld-spot inspection directly on the shop floor.

Siemens’ Inspekto system brings AI-driven visual quality inspection to manufacturers of all sizes. The system can be trained to recognize defects using as few as twenty product samples in under an hour, making automated quality control accessible even to small and medium-sized manufacturers in industries like electronics and metal forming. The AI learns to identify defects specific to each product without requiring extensive programming or large training datasets.

The company’s MindSphere industrial IoT platform provides the data infrastructure foundation for AI applications. MindSphere collects, stores, and contextualizes data from thousands of sensors and systems across manufacturing operations, providing the clean, structured data that AI systems require. Advanced analytics and machine learning models run on this platform to monitor equipment health, predict maintenance needs, optimize energy consumption, identify quality issues, and provide real-time visibility into operations.

Digital twin technology represents another area where Siemens leads. At NVIDIA GTC conferences in 2025, Siemens demonstrated a new technology stack that enables engineers to rapidly design, optimize, and manage highly realistic digital twins of entire factories. Built on the integration between Siemens Xcelerator and NVIDIA Omniverse, this technology brings together 3D visualization, physics-based simulation, and real-time factory data into unified environments. Engineers can design complete production facilities in weeks instead of months, test dozens of layout options virtually before any physical construction, train robotic systems in simulation long before deployment, and use the same digital model throughout design, commissioning, and ongoing operations.

Siemens maintains a full chip-to-grid value chain capability, meaning it can provide integrated solutions from semiconductor design and manufacturing through power generation, distribution, and consumption. For manufacturers building AI-powered factories and data centers, this comprehensive capability enables optimized, energy-efficient operations where power systems, cooling infrastructure, computing systems, and building management work as a unified whole.

Looking toward 2026 and beyond, Siemens is advancing industrial AI toward greater autonomy. Advanced AI agents work seamlessly across the Industrial Copilot portfolio, executing entire AI-powered processes without human intervention. The company is also pioneering new approaches to operational technology cybersecurity by integrating NVIDIA BlueField DPUs, leveraging accelerated computing for AI-driven threat detection and response in industrial systems.

For manufacturing companies evaluating AI investments, Siemens offers particular advantages including comprehensive integration from design through production to service, proven scalability with implementations at the world’s largest manufacturers, deep domain expertise in specific industries accumulated over decades, strong ecosystem with partnerships spanning technology leaders, and a balanced approach that augments human workers rather than attempting to eliminate them.

The company’s influence on the AI in manufacturing market is substantial, both through direct sales and through its role in defining standards and best practices that shape how the industry approaches digitalization and AI adoption.

2. NVIDIA Corporation: The AI Computing Engine

While NVIDIA is widely recognized for designing the graphics processing units that power AI systems globally, the company’s role in manufacturing extends far beyond chip design. NVIDIA has positioned itself as a complete platform provider for industrial AI, offering not just computing hardware but comprehensive software frameworks, pre-trained AI models, simulation environments, and extensive partnerships with industrial leaders.

The foundation of NVIDIA’s manufacturing AI offering is its computing platform. The company’s GPUs, including the Blackwell architecture and the Jetson series for edge deployment, provide the massive parallel processing capability required for AI workloads. Training a computer vision model to detect manufacturing defects might require processing millions of images through billions of mathematical operations—a task that would take weeks on traditional processors but can be accomplished in hours on NVIDIA GPUs.

NVIDIA Omniverse represents the company’s vision for industrial digitalization. Omniverse is a platform for building and operating physics-accurate, AI-powered digital twins and simulation environments. Manufacturing companies use Omniverse to create virtual replicas of factories where they can test new processes, optimize layouts, train robots, and identify potential problems before implementing changes in the physical world. The platform uses Universal Scene Description, an open standard that enables different 3D tools and systems to work together seamlessly.

The Isaac robotics platform provides AI capabilities specifically designed for manufacturing robotics. Isaac Manipulator offers foundation models, tools, and libraries that help robots handle manipulation tasks—picking, placing, assembling, and working with objects. Isaac Perceptor provides advanced perception capabilities, enabling robots to understand their environment, recognize objects, and navigate complex spaces. These platforms dramatically reduce the development time required to deploy capable robots in manufacturing environments.

NVIDIA’s AI Enterprise software provides a production-ready platform for deploying AI applications at scale in manufacturing environments. This includes frameworks for machine learning and deep learning, pre-trained models for common manufacturing tasks like quality inspection and predictive maintenance, tools for managing and monitoring AI systems in production, and security and support appropriate for mission-critical industrial applications.

The company’s partnerships define much of its impact on manufacturing. The Siemens partnership brings NVIDIA computing and AI capabilities into Siemens’ comprehensive industrial platform. The Rockwell Automation collaboration deploys edge-based generative AI capabilities using NVIDIA Nemotron Nano technology in FactoryTalk Design Studio and other Rockwell systems. The Microsoft partnership integrates Azure AI services with NVIDIA’s hardware and software for industrial applications.

NVIDIA’s AI Blueprints provide reference architectures and workflows for common manufacturing AI applications. Rather than building AI systems from scratch, manufacturers can start with proven blueprints for video search and summarization for factory floor monitoring, predictive maintenance for critical equipment, quality control using computer vision, supply chain optimization, and autonomous mobile robots.

For manufacturers building AI capabilities, NVIDIA offers several distinct advantages. The company’s GPUs have become the de facto standard for AI computing, ensuring compatibility with the broadest range of AI frameworks and tools. The comprehensive platform approach means manufacturers can source computing hardware, software frameworks, pre-trained models, and development tools from a single vendor. Strong partnerships with industrial leaders provide proven integration paths. Continuous innovation ensures access to cutting-edge capabilities as AI technology advances.

The company’s influence extends through the entire manufacturing AI ecosystem. Virtually every significant manufacturing AI deployment relies on NVIDIA technology at some level, whether through cloud-based training using NVIDIA GPUs in data centers, edge inference using Jetson modules in manufacturing equipment, or simulation and digital twin environments built on Omniverse.

NVIDIA’s vision for manufacturing centers on physical AI—robots and autonomous systems that can operate in the unstructured, dynamic environments of real factories. As these technologies mature through 2026 and beyond, NVIDIA’s platforms and partnerships position it as the computing backbone enabling increasingly autonomous manufacturing operations.

3. IBM: Enterprise AI and Manufacturing Intelligence

IBM brings decades of industrial computing experience to the AI era, combining deep vertical expertise in manufacturing with cutting-edge AI capabilities through its Watsonx platform. While IBM faces strong competition from cloud-native AI companies, its established relationships with global manufacturers and focus on enterprise-ready, hybrid cloud solutions maintain its influential position in manufacturing AI.

The Watsonx platform provides IBM’s foundation for manufacturing AI applications. Watsonx combines large language models with traditional machine learning, providing manufacturers with tools for building, deploying, and managing AI across their operations. The platform’s governance features address critical manufacturing concerns around model explainability, bias detection, and regulatory compliance.

IBM Maximo represents the company’s flagship offering for manufacturing AI, specifically focused on asset performance management and predictive maintenance. Maximo uses AI to analyze data from sensors, maintenance records, and operating conditions to predict when equipment is likely to fail, automatically generate work orders and schedule maintenance, optimize inventory of spare parts based on predicted needs, identify root causes of recurring problems, and provide mobile access to maintenance information and AI-powered guidance for technicians.

The Maximo Application Suite extends beyond basic maintenance to encompass comprehensive enterprise asset management. Health and predict features use machine learning to monitor equipment condition and forecast remaining useful life. Monitor capabilities provide real-time visibility into asset performance across facilities. Manage functions handle work orders, inventory, and maintenance planning. Assist provides augmented reality guidance for maintenance and inspection tasks.

IBM’s deep industry expertise distinguishes its approach. The company maintains dedicated teams with extensive knowledge in automotive manufacturing, aerospace and defense, electronics, pharmaceuticals, food and beverage, and other sectors. This domain knowledge enables IBM to configure AI systems that understand industry-specific requirements, regulations, and best practices rather than providing generic solutions that manufacturers must extensively customize.

IBM’s hybrid cloud architecture addresses a critical manufacturing requirement. Many manufacturers have substantial investments in on-premise infrastructure, legacy systems that cannot easily move to public clouds, and data sovereignty requirements that mandate certain information remain within specific geographic boundaries. IBM’s hybrid approach enables AI capabilities to work seamlessly across on-premise systems, private clouds, and public cloud services, moving workloads based on requirements rather than forcing everything into a single architecture.

The company’s Manufacturing Applications Portfolio includes specialized AI solutions for production optimization, where AI analyzes production data to identify efficiency opportunities and recommend process improvements. Quality management applications use computer vision and machine learning to automate inspection, detect defects, and analyze quality trends. Supply chain intelligence solutions employ AI to optimize inventory, predict demand, and identify supply risks. Energy management capabilities help manufacturers reduce energy consumption through AI-driven optimization.

IBM’s PowerAI Vision provides deep learning capabilities for visual inspection applications. Manufacturers like SMART Modular Technologies use PowerAI Vision to detect errors in manufacturing processes that would be extremely difficult for human inspectors to catch consistently. The system can be trained to recognize defects using relatively small datasets and provides explanations for its decisions, critical for quality processes that require documentation and traceability.

For semiconductor manufacturing, IBM has partnered with companies like Panasonic to develop specialized AI systems for chip packaging. These systems optimize the complex process of placing components on circuit boards, a task requiring extreme precision where AI can identify optimal placement strategies that maximize yield and reliability.

IBM’s commitment to responsible AI resonates with manufacturing companies concerned about AI governance. The company provides tools for documenting AI model development and deployment, monitoring for bias or drift in model performance, explaining AI decisions to auditors and regulators, and ensuring AI systems comply with industry-specific requirements.

Looking forward, IBM is positioning Watsonx as the enterprise AI platform for manufacturers pursuing digital transformation. The July 2025 launch of Granite 3.0 models, IBM’s most advanced AI offerings, includes capabilities specifically relevant to manufacturing such as improved reasoning about complex processes, better understanding of technical documentation and procedures, enhanced code generation for industrial automation, and stronger multilingual capabilities for global operations.

For manufacturers seeking proven enterprise AI solutions with strong governance, deep industry knowledge, and hybrid cloud flexibility, IBM remains a significant player despite facing intense competition from newer, more agile AI-native companies.

4. Rockwell Automation: Automation Evolving to Autonomy

Rockwell Automation has built its business on industrial automation for decades, and the company is now leading the transformation from programmed automation to AI-driven autonomy. Headquartered in Milwaukee, Wisconsin, with approximately 26,000 employees serving customers in more than one hundred countries, Rockwell combines deep operational technology expertise with cutting-edge AI capabilities.

The company’s vision, articulated clearly at its Automation Fair 2025 event, centers on autonomy rather than simply more automation. As Chief Technology Officer Cyril Perducat explained, the boundary between human intelligence and robotic intelligence is blurring, creating opportunities to reinvent what automation means. Rockwell envisions factories where equipment operates autonomously and integrates seamlessly into highly orchestrated production systems, yet the goal is empowering people rather than eliminating them.

Rockwell’s AI strategy manifests through several key platforms and capabilities. FactoryTalk Design Studio, enhanced with Copilot capabilities powered by NVIDIA’s technology, enables engineers to use natural language prompts to generate automation code, significantly accelerating development. The integration of NVIDIA Nemotron Nano technology brings conversational, reasoning-based AI directly to the plant floor without relying on cloud infrastructure, enabling secure, real-time decision-making at the edge.

FactoryTalk Analytics LogixAI uses streaming data from controllers combined with machine learning to make predictions about process performance and identify optimization opportunities. The system analyzes patterns in real-time operational data, recognizing anomalies and trends that indicate potential problems or efficiency gains.

FactoryTalk Analytics GuardianAI focuses specifically on predictive maintenance, monitoring equipment condition and alerting operators when components need repair or replacement before failures occur. This predictive approach prevents unplanned downtime, the costliest problem facing most manufacturers.

The company’s partnership with NVIDIA accelerates industrial AI adoption by bringing advanced AI capabilities to manufacturing environments with limited space and power. Using NVIDIA’s open-source Nemotron-Nano-9B-v2 model optimized for edge deployment, Rockwell has created AI systems capable of running directly on industrial equipment without external cloud infrastructure. This approach addresses critical manufacturing requirements including low latency for real-time decisions, data security since information never leaves the facility, reliability even without internet connectivity, and reduced operating costs.

Rockwell’s partnership with Microsoft integrates Azure OpenAI services into Rockwell platforms, combining Microsoft’s language models with Rockwell’s industrial expertise. This enables conversational interfaces for operators, automated generation of standard operating procedures, and AI-assisted troubleshooting.

The company’s elastic Manufacturing Execution System portfolio, announced in December 2025, represents a strategic evolution toward cloud-native, interoperable platforms that unify operational technology and information technology. Traditional MES solutions often operate in silos, limiting visibility across systems. Rockwell’s elastic MES provides a unified platform connecting the manufacturing lifecycle from materials and inventory through production and tooling. Embedded analytics and AI-driven insights keep production agile and optimized.

Rockwell’s State of Smart Manufacturing Report, surveying over 1,500 manufacturers across seventeen leading industrial nations, provides valuable insights into AI adoption trends. The 2025 report found that ninety-five percent of manufacturers are investing in AI and machine learning, eighty-three percent expect to use generative AI in operations, and quality control remains the top AI use case, with fifty percent planning to apply AI and machine learning to support product quality.

The report also revealed that forty-eight percent of manufacturers plan to repurpose or hire additional workers due to smart manufacturing investments, reinforcing Rockwell’s message that AI augments rather than replaces human workers. Forty-one percent are using AI and automation specifically to help close skills gaps and address labor shortages, a critical issue as experienced workers retire.

Real-world deployments demonstrate Rockwell’s capabilities. The company’s new advanced automation facility in Wisconsin serves as a working demonstration of AI-enabled manufacturing, featuring digital twins for virtual design and testing, automated material handling systems guided by AI, energy management optimized through machine learning, and integrated workforce training using augmented reality.

For manufacturers pursuing smart manufacturing transformation, Rockwell offers several distinct strengths including deep operational technology expertise built over decades, comprehensive automation hardware and software portfolio, strong partnerships with NVIDIA, Microsoft, and others bringing cutting-edge AI capabilities, industry-leading research and insights through annual reports and studies, and balanced approach emphasizing human-AI collaboration.

The company’s evolution from traditional automation provider to autonomy enabler positions it well for the next phase of industrial transformation, where AI systems take on increasing decision-making responsibility while humans focus on strategic oversight and complex problem-solving.

5. GE Vernova: Power, Sustainability, and Manufacturing Intelligence

GE Vernova emerged from the reorganization of General Electric as a focused entity dedicated to power generation, sustainable energy, and electrification. While this might seem tangential to manufacturing AI, Vernova’s manufacturing execution systems, energy management AI, and sustainability-focused intelligence solutions make it highly relevant for manufacturers pursuing efficient, low-carbon operations.

Headquartered in Cambridge, Massachusetts, GE Vernova combines GE’s century-long heritage in industrial equipment with modern AI capabilities focused on energy efficiency and sustainability. The company’s Proficy platform provides the core of its manufacturing AI offerings.

Proficy for Manufacturing uses AI to optimize production processes, analyzing sensor data, production records, and quality metrics to identify inefficiencies and recommend improvements. The system can detect subtle patterns that indicate processes are drifting from optimal conditions, enabling proactive adjustments before quality or efficiency suffers.

Proficy for Sustainability Insights represents GE Vernova’s distinctive contribution to manufacturing AI. This software uses sensors and machine learning to show how manufacturing facilities can work more efficiently from an energy and environmental perspective. The system monitors consumption of electricity, natural gas, water, and steam, correlates this data with production output and conditions, identifies opportunities to reduce consumption without sacrificing production, and tracks key performance indicators including Scope 1 and Scope 2 carbon emissions, water usage, energy efficiency, and renewable energy utilization.

For manufacturers facing increasing pressure to reduce environmental impact and report sustainability metrics accurately, Proficy for Sustainability Insights provides AI-powered visibility and optimization that would be extremely difficult to achieve manually. The system essentially treats sustainability as a production parameter that can be measured, analyzed, and optimized using the same AI techniques applied to quality and efficiency.

GE Vernova’s expertise in power generation and grid management brings unique capabilities to manufacturing AI, particularly for energy-intensive industries. The company’s GridOS software uses AI to optimize power distribution and consumption, reduce energy costs through intelligent load management, integrate renewable energy sources effectively, and improve grid stability and resilience.

For large manufacturers operating their own power generation or managing complex electrical systems, GE Vernova’s AI capabilities bridge the gap between manufacturing operations and power systems. AI optimization can shift energy-intensive processes to times when power is cheaper or when renewable generation is high, coordinate across multiple facilities to optimize overall energy use, and predict and prevent power quality issues that could disrupt production.

The company’s Manufacturing Execution Systems provide comprehensive control and visibility across production operations. AI enhancements enable automatic scheduling optimization based on demand forecasts, equipment availability, and resource constraints. Real-time quality monitoring uses machine learning to detect anomalies and potential defects. Predictive maintenance analyzes equipment data to forecast failures and schedule preventive interventions. Performance analysis identifies bottlenecks and opportunities for improvement.

GE Vernova’s industrial IoT platform collects and contextualizes data from manufacturing equipment, building systems, and power infrastructure. This unified data foundation enables AI models that optimize across traditionally separate domains. For example, an AI system might adjust production schedules based not just on orders and equipment availability, but also on energy costs and carbon intensity of the power grid at different times.

Looking toward 2026, GE Vernova is advancing AI capabilities focused on sustainability and resilience. Climate change creates increasing volatility in energy costs and availability. GE Vernova’s AI systems help manufacturers navigate this volatility by predicting energy price fluctuations, optimizing consumption dynamically, integrating on-site renewable generation and storage, and maintaining production resilience despite grid instability.

For manufacturers where energy costs represent a significant portion of production expenses, or where sustainability is a strategic priority, GE Vernova offers specialized capabilities that broader manufacturing AI providers may not emphasize. The company’s deep expertise in power systems and decades of experience in heavy industry provide credibility and proven solutions for complex industrial environments.

6. Intel Corporation: Edge Intelligence and Optimized Computing

Intel’s position in manufacturing AI centers on the processors and accelerators that enable AI to run not just in data centers but directly at the edge—on manufacturing equipment, quality inspection systems, autonomous robots, and factory floor devices where real-time decision-making occurs. While NVIDIA dominates AI training and high-performance inference, Intel has carved out a significant role providing computing platforms optimized for industrial deployment.

Intel’s portfolio includes several products specifically relevant to manufacturing AI. Xeon processors provide the foundation for industrial servers and edge computing systems, with advanced instructions and features optimized for AI workloads. Xeon processors power the industrial PCs and edge servers that run AI applications in factories.

The Intel Movidius vision processing units specialize in computer vision applications with low power consumption, making them ideal for battery-powered inspection systems, autonomous mobile robots, and edge cameras. Movidius processors can run neural networks for object detection, classification, and tracking directly on camera devices.

Intel’s Habana accelerators, including Gaudi processors, provide alternatives to GPU-based AI computing with different performance and cost characteristics. Some manufacturers choose Habana accelerators for specific AI workloads where their architecture provides advantages.

OpenVINO, Intel’s open-source toolkit, enables developers to optimize AI models for Intel hardware and deploy them across diverse computing platforms. OpenVINO supports models from popular frameworks like TensorFlow and PyTorch, converts them to efficient formats for Intel hardware, and provides runtime components for deployment. This toolkit is particularly valuable for manufacturers deploying AI across heterogeneous environments where different types of Intel processors handle different tasks.

Intel’s edge AI reference designs provide blueprints for building manufacturing AI systems. These designs specify hardware configurations, software stacks, and validation results for applications including vision-based quality inspection, predictive maintenance using vibration and sound analysis, automated guided vehicles and mobile robots, and defect detection using thermal imaging or X-ray.

The company’s partnerships extend its reach in manufacturing AI. Intel collaborates with industrial equipment manufacturers to integrate AI capabilities into controllers, drives, and factory automation devices. Partnerships with software vendors ensure popular manufacturing execution systems, quality management platforms, and analytics tools run efficiently on Intel hardware.

For manufacturers building or purchasing AI-enabled equipment, Intel’s pervasive presence in computing provides important advantages. The extensive ecosystem of software tools and frameworks supports Intel processors. Proven reliability in industrial environments comes from decades of Intel processors operating in harsh conditions. Roadmap stability gives manufacturers confidence their investments will remain relevant.

Intel’s focus on edge AI addresses a fundamental manufacturing requirement. While cloud-based AI works well for applications like demand forecasting or supply chain optimization, many manufacturing AI use cases demand edge deployment. Quality inspection systems need millisecond latency to keep up with production speeds. Robots require real-time perception and decision-making. Predictive maintenance must continue operating even if internet connectivity is lost. Edge AI on Intel processors enables these critical applications.

Looking forward, Intel is advancing neuromorphic computing through its Loihi research project. Neuromorphic processors mimic brain architecture, potentially enabling AI systems that learn continuously, consume minimal power, and handle complex sensor processing. While still primarily research-focused, neuromorphic computing could eventually transform manufacturing AI by enabling smarter sensors and more capable autonomous systems with dramatically lower power requirements.

For manufacturing companies, Intel’s role is often invisible but essential. The processors powering industrial PCs, edge servers, and embedded systems throughout factories frequently bear Intel logos. As AI workloads increasingly run at the edge rather than in centralized locations, Intel’s technology and optimization tools become ever more important to manufacturing intelligence.

7. C3 AI: Enterprise AI Applications for Manufacturing

C3 AI has built its business around providing pre-built, configurable AI applications for enterprises, with manufacturing representing a significant focus area. Based in Redwood City, California, C3 AI offers a platform approach that enables manufacturers to deploy AI capabilities quickly without building everything from scratch.

The C3 AI Platform provides the foundation, offering tools for data integration from diverse sources, machine learning model development and deployment, and AI application building and customization. The platform’s value proposition centers on accelerating AI adoption by providing production-ready infrastructure rather than requiring manufacturers to assemble components from multiple vendors.

C3 AI Process Optimization helps manufacturers increase production yield and efficiency by analyzing production data to identify optimization opportunities, simulating different operational strategies to find optimal approaches, recommending specific process adjustments to improve outcomes, and continuously learning from results to refine recommendations over time.

C3 AI Production Schedule Optimization addresses one of manufacturing’s most complex challenges by developing demand forecasts using AI models that consider multiple factors, generating optimized production schedules that balance efficiency with responsiveness, adapting dynamically as conditions change, and coordinating across multiple production lines and facilities.

C3 AI Reliability provides failure prediction and predictive maintenance capabilities. The application analyzes sensor data, maintenance records, and environmental conditions to predict when equipment failures are likely, generates maintenance recommendations prioritized by impact and urgency, optimizes spare parts inventory based on predicted needs, and tracks results to continuously improve predictions.

C3 AI Energy Management helps manufacturers reduce energy consumption and costs through AI-driven optimization. The system monitors energy usage across facilities, identifies opportunities to reduce consumption without impacting production, automatically adjusts systems like HVAC and lighting based on occupancy and production schedules, and provides visibility into energy costs and sustainability metrics.

The C3 AI Inventory Optimization application uses AI to maintain optimal inventory levels by predicting demand more accurately than traditional methods, identifying slow-moving inventory that ties up capital, determining safety stock levels that balance availability with carrying costs, and optimizing reorder points and quantities.

C3 AI Supply Network Risk monitors supply chains for potential disruptions. The application tracks suppliers, logistics providers, and materials flows, identifies risk factors including geopolitical instability, weather events, and financial stress, predicts impacts on production if disruptions occur, and recommends mitigation strategies.

C3 AI’s approach differs from platform providers like NVIDIA or Siemens in that it focuses on delivering complete applications rather than tools for building AI systems. For manufacturers who need specific AI capabilities quickly and lack extensive data science teams, this application approach can accelerate value realization.

The company serves manufacturing clients across industries, with particular strength in energy-intensive sectors like oil and gas, chemicals, and utilities, as well as discrete manufacturing including aerospace, defense, and industrial equipment. C3 AI’s applications often address use cases where large amounts of time-series data from sensors and equipment provide the foundation for AI-driven insights.

For manufacturers evaluating C3 AI, key considerations include whether the pre-built applications align with their priority use cases, their willingness to work within C3 AI’s platform rather than building on more open architectures, the total cost of ownership compared to building equivalent capabilities using other tools, and the strategic implications of dependence on a single vendor for critical AI capabilities.

Looking forward, C3 AI is advancing its generative AI capabilities, adding large language model capabilities to enable conversational interfaces for its applications, natural language querying of manufacturing data, and automated report and documentation generation.

8. Honeywell International: Process Manufacturing Intelligence

Honeywell International brings expertise in process manufacturing—industries like chemicals, oil and gas, pharmaceuticals, and food and beverage where materials flow through complex processes rather than being assembled from discrete components. The company’s AI capabilities focus on optimizing these continuous processes for efficiency, quality, and safety.

Honeywell’s Forge platform provides the foundation for its manufacturing AI offerings. Forge is an industrial IoT and analytics platform that collects data from process equipment, contextualizes it based on engineering models and domain knowledge, and applies AI to optimize operations.

Honeywell Forge for Industrial uses machine learning to model complex process interactions, identifying optimal operating conditions, predicting how processes will respond to changes, detecting anomalies that indicate equipment problems or quality issues, and providing operators with AI-powered recommendations.

The company’s advanced process control solutions incorporate AI to optimize control strategies. Traditional control systems maintain processes within acceptable ranges; AI-enhanced control actively optimizes for efficiency and quality. The systems continuously adjust control parameters based on changing conditions, coordinate across multiple control loops to optimize system-level performance, adapt to equipment aging and process drift, and reduce variability that leads to quality issues and waste.

Honeywell’s asset performance management combines IoT data collection with AI-driven analytics for predictive maintenance. Sensors monitor critical equipment, AI models predict remaining useful life and failure probability, maintenance is scheduled proactively based on condition rather than fixed intervals, and root cause analysis identifies why failures occur.

For pharmaceuticals and other highly regulated industries, Honeywell provides specialized AI capabilities that maintain compliance while optimizing operations. The systems ensure all AI decisions are documented and explainable for regulatory audits, maintain batch genealogy and traceability, implement procedural controls required by regulations, and optimize within constraints defined by regulatory requirements.

Honeywell’s expertise in process safety brings important capabilities to manufacturing AI. The company’s AI systems can predict and prevent hazardous conditions, optimize operations while maintaining safety margins, respond appropriately to abnormal situations, and analyze incidents to prevent recurrence.

Looking toward 2026, Honeywell is advancing its AI capabilities in predictive analytics for supply chains, particularly for process industries where supply disruptions have severe consequences. Digital twin technology that combines process models with AI creates virtual environments for operator training and process optimization. The company is also developing autonomous operations capabilities where AI systems manage processes with minimal human intervention.

For process manufacturers seeking AI solutions from a provider with deep domain expertise and proven safety credentials, Honeywell represents a strong option. The company’s decades of experience in process industries and understanding of the specific challenges they face distinguishes its offerings from more generic manufacturing AI platforms.

9. ABB: Robotics and Electrification Intelligence

ABB, the Swiss-Swedish multinational, brings together robotics, industrial automation, and electrification expertise with increasing AI capabilities. The company’s position in manufacturing AI centers on intelligent robots, AI-enhanced automation controllers, and energy management systems.

ABB’s robotics division provides industrial robots integrated with AI capabilities for vision-guided operations where robots use AI-powered computer vision to locate parts, adapt to variations, and handle objects with complex shapes. Collaborative robots with AI enable safe human-robot collaboration, learning optimal movements through demonstration rather than programming, and adapting behavior based on the human partner’s actions.

The company’s machine learning capabilities enable robots to improve their performance over time, optimizing movements for speed and precision, learning to handle variations in parts or processes, and adapting to tool wear or environmental changes.

ABB’s Ability platform provides the data infrastructure and analytics foundation for manufacturing AI. Ability collects and harmonizes data from ABB equipment and third-party systems, applies analytics and machine learning for insights, enables condition-based and predictive maintenance, and optimizes energy consumption.

ABB’s AC drives and motion control systems now incorporate AI for performance optimization. The systems automatically tune control parameters for optimal performance, predict and prevent motor failures, optimize energy efficiency based on load profiles, and coordinate multiple drives for system-level optimization.

For manufacturers pursuing electrification of processes previously relying on fossil fuels, ABB’s AI capabilities optimize the transition. The systems help balance loads to avoid exceeding electrical capacity, integrate renewable energy sources effectively, manage battery storage for optimal economics, and reduce peak demand charges through intelligent load shifting.

ABB’s YuMi collaborative robot series demonstrates the company’s vision for human-robot collaboration enhanced by AI. YuMi robots work safely alongside humans without safety cages, learn new tasks through intuitive teaching rather than programming, adapt their speed and movements based on the human partner’s presence, and coordinate with humans to complete complex assembly tasks.

Looking forward, ABB is advancing autonomous mobile robots with AI-enabled navigation and task planning. The company is developing digital twin environments for virtual robot commissioning and programming, and exploring generative AI for robot programming assistance.

For manufacturers seeking intelligent robotics and electrification solutions, ABB offers deep expertise in both domains, comprehensive equipment portfolio from robots to drives to control systems, and proven reliability in demanding manufacturing environments.

10. Microsoft: Cloud AI and Industrial Partnerships

Microsoft’s position in manufacturing AI stems from its Azure cloud platform, partnerships with industrial leaders, and decades of experience providing software to enterprises. While not traditionally considered a manufacturing company, Microsoft’s technology underpins numerous manufacturing AI deployments, and its partnerships position it as an important enabler of industrial intelligence.

Azure AI provides comprehensive machine learning and AI services that manufacturers use to build custom AI applications, deploying pre-trained models for common tasks, and operating AI at scale with enterprise governance. Azure Machine Learning offers tools for data preparation, model training, deployment, and monitoring that enable manufacturers to develop custom AI solutions tailored to their specific processes and needs.

Microsoft’s partnership with Siemens integrates Azure OpenAI Service into Siemens’ Industrial Copilot, combining Microsoft’s language models with Siemens’ industrial domain knowledge. Similar partnerships with Rockwell Automation bring Azure AI capabilities into factory automation systems.

Azure IoT provides the connectivity and data management foundation for manufacturing AI. The platform collects data from factory equipment, processes and analyzes it at the edge or in the cloud, stores time-series data optimized for manufacturing workloads, and enables secure, scalable IoT deployments.

Microsoft’s focus on generative AI brings new capabilities to manufacturing. Large language models enable conversational interfaces for operators, automated generation of documentation and procedures, natural language queries against manufacturing data, and AI assistants that help workers find information and solve problems.

Dynamics 365, Microsoft’s enterprise resource planning and customer relationship management suite, increasingly incorporates AI for demand forecasting, inventory optimization, production planning, and customer service. These AI enhancements help manufacturers better coordinate operations with demand and manage relationships with suppliers and customers.

For manufacturers already using Microsoft’s platforms for office productivity, business applications, and IT infrastructure, Azure provides a natural path to AI adoption. The integrated ecosystem, familiar tools and interfaces, and comprehensive support make Azure an attractive option, particularly for manufacturers without extensive AI expertise.

Microsoft’s HoloLens mixed reality platform finds applications in manufacturing for AI-assisted maintenance and repair, remote expert assistance using augmented reality, training using virtual environments, and quality inspection with AI-powered overlay guidance.

Looking forward, Microsoft is advancing industrial AI through continued investment in Azure AI services, deeper partnerships with industrial leaders, generative AI capabilities specifically tuned for industrial applications, and integration between operational technology data and enterprise business systems.

For manufacturers seeking a comprehensive cloud platform with strong enterprise support, extensive AI capabilities, and proven scalability, Microsoft Azure represents a significant option, particularly when combined with Microsoft’s industrial partnerships.

Conclusion: The Intelligent Factory of 2026

The manufacturing industry in 2026 bears little resemblance to factories of even a decade ago. Artificial intelligence has moved from experimental pilots to production-critical systems managing quality control, predicting maintenance needs, optimizing processes, and increasingly making autonomous decisions. The companies explored in this guide—Siemens, NVIDIA, IBM, Rockwell Automation, GE Vernova, Intel, C3 AI, Honeywell, ABB, and Microsoft—are not just providing technology but fundamentally enabling a new era of manufacturing intelligence.

As we move deeper into 2026 and beyond, manufacturing AI will continue evolving at remarkable pace. The factories of tomorrow will be places where humans and AI systems collaborate seamlessly, where physical and digital operations intertwine through AI-powered digital twins, where sustainability and profitability advance together through intelligent optimization, and where manufacturing becomes not just more efficient but fundamentally more capable, flexible, and resilient. The companies leading this transformation today are not just building better factories—they are reimagining what manufacturing can be.