Top 10 Biomass Energy Producers In 2026

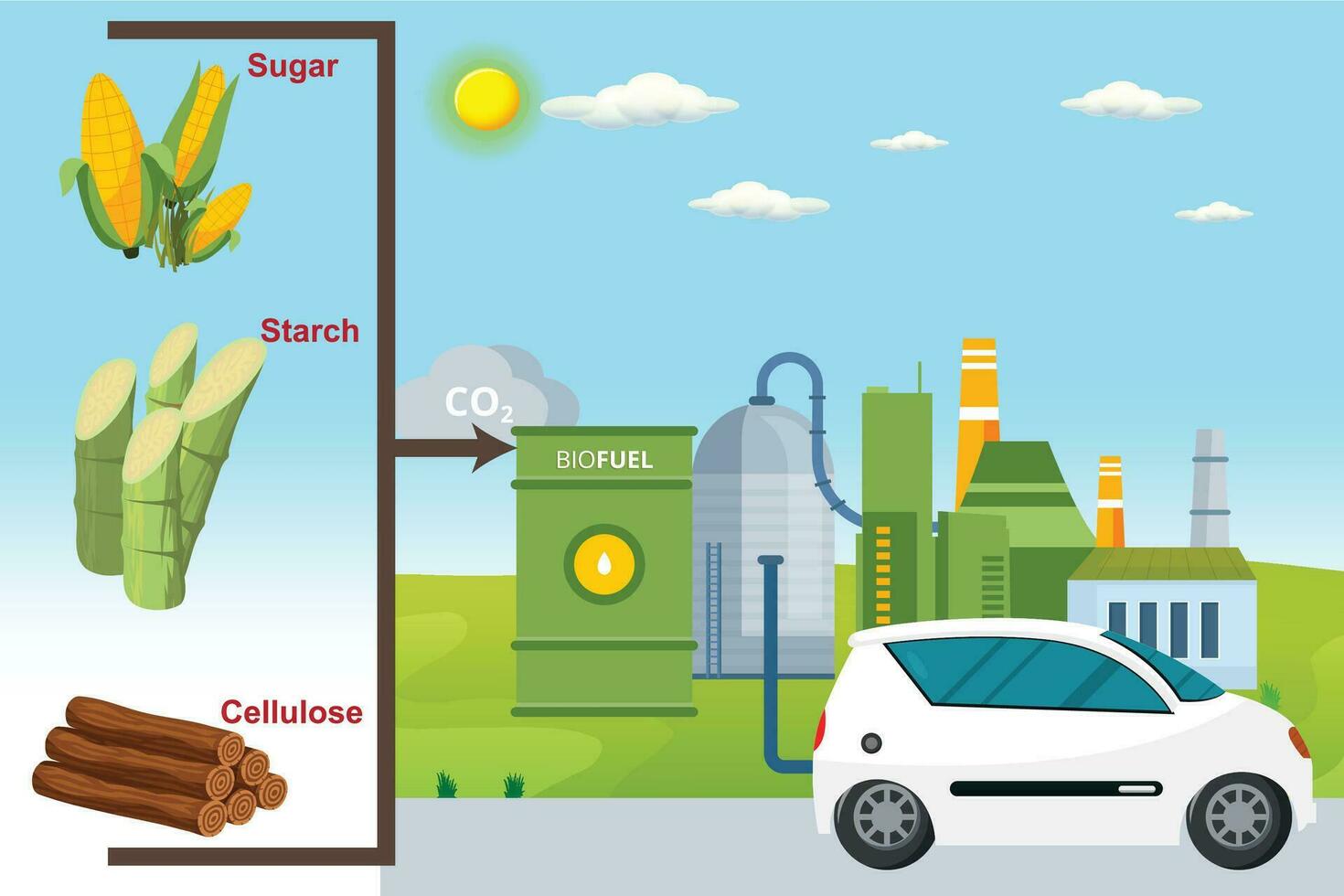

As the world accelerates its transition away from fossil fuels, biomass energy has emerged as a critical component of the renewable energy portfolio. Unlike intermittent sources such as solar and wind that depend on weather conditions, biomass provides reliable, dispatchable renewable power that can operate around the clock. This unique capability makes biomass energy particularly valuable for maintaining grid stability while supporting the integration of other renewable sources into the energy mix.

The companies profiled in this comprehensive analysis represent the vanguard of biomass energy production in 2026, combining established energy expertise with innovative approaches to sustainable fuel sourcing, efficient conversion technologies, and integration with broader renewable energy systems. These industry leaders are not merely replacing coal with wood pellets; they are pioneering technologies and business models that demonstrate how organic materials can contribute meaningfully to global decarbonization efforts while supporting rural economies and responsible forest management.

1. Drax Group: The United Kingdom’s Biomass Power Leader

Drax Group stands as the most prominent biomass energy producer globally, operating the largest biomass power station in the world at Selby in North Yorkshire, England. The company has undergone a remarkable transformation over the past two decades, evolving from one of Europe’s largest coal-fired power generators into a renewable energy leader focused on sustainable biomass, hydroelectric power, and pioneering carbon removal technologies.

The Drax Power Station, originally commissioned in 1974 as a coal facility with total generating capacity exceeding three thousand nine hundred megawatts, has systematically converted its generating units from coal to compressed wood pellets since 2013. Currently operating with a biomass capacity of two thousand six hundred megawatts, Drax provides approximately five to six percent of the United Kingdom’s total electricity supply through renewable generation. The facility burns approximately seven million tonnes of wood pellets annually, sourced primarily from sustainably managed forests in North America and Europe, making it the world’s largest consumer of industrial wood pellets.

What distinguishes Drax from other biomass operators is its vertically integrated supply chain and commitment to producing its own fuel. The company operates a global network of eighteen pellet manufacturing plants across thirteen locations in the United States and Canada, with combined production capacity exceeding four million tonnes annually in 2024. This vertical integration allows Drax to control quality, reduce supply chain risks, and optimize costs while ensuring sustainable sourcing practices that meet rigorous environmental standards including Sustainable Biomass Program certification.

Drax has positioned itself at the forefront of carbon removal technology through its development of bioenergy with carbon capture and storage. In 2024, the company launched Elimini, a dedicated subsidiary focused on delivering carbon removals at megaton scale by capturing and permanently sequestering carbon dioxide generated during biomass combustion. This technology represents the only proven method capable of generating dispatchable renewable electricity while simultaneously removing carbon dioxide from the atmosphere, potentially achieving carbon-negative power generation. The company maintains an ambitious target to become carbon negative by 2030 and reach net zero across its entire value chain by 2040.

Recent strategic developments underscore Drax’s evolution beyond electricity generation. In December 2024, the company reached agreement with Pathway Energy to supply over one million tonnes of sustainable biomass pellets annually to Pathway’s proposed sustainable aviation fuel plant in Port Arthur, Texas, with construction beginning in early 2026 and commercial production expected by 2029. This deal represents Drax’s largest third-party supply arrangement and demonstrates the company’s strategy to supply biomass for hard-to-abate sectors beyond power generation, including aviation decarbonization.

2. ENGIE: French Energy Giant’s Global Biomass Operations

ENGIE, headquartered in Paris, stands as one of Europe’s largest energy companies and operates numerous biomass power plants globally as part of its comprehensive renewable energy portfolio. With annual revenue exceeding sixty billion dollars and operations spanning numerous countries, ENGIE brings financial strength and technical expertise that few competitors can match to its biomass energy initiatives.

The company’s biomass strategy emphasizes diversity in both feedstock sources and conversion technologies. ENGIE operates biomass-fired power plants that utilize wood chips, agricultural residues, and biogas from organic waste, demonstrating the company’s understanding that biomass energy encompasses multiple pathways and feedstock options. This diversity allows ENGIE to optimize fuel selection based on regional availability, cost considerations, and carbon intensity profiles while maintaining operational flexibility.

ENGIE has positioned itself as a pioneer in biogas and green hydrogen production, recognizing that biomass conversion extends beyond direct combustion for electricity generation. The company’s biogas operations capture methane from agricultural operations, food waste, and wastewater treatment facilities, converting this potent greenhouse gas into renewable electricity and heat. This approach addresses multiple environmental challenges simultaneously: reducing methane emissions, managing organic waste, and generating renewable energy from materials that might otherwise decompose while releasing greenhouse gases.

The company’s commitment to sustainability extends to comprehensive lifecycle assessments of its biomass operations, evaluating not only direct emissions from power generation but also emissions associated with feedstock production, transportation, and processing. ENGIE has invested substantially in certification systems and traceability mechanisms that verify sustainable sourcing and quantify carbon reduction benefits, responding to increasing scrutiny of biomass energy’s environmental credentials.

Looking toward 2026 and beyond, ENGIE continues investing in next-generation biomass technologies including advanced gasification systems that improve conversion efficiency and reduce emissions, co-firing arrangements that combine biomass with other fuels to optimize economics and environmental performance, and integration of biomass generation with district heating networks that capture waste heat for residential and commercial applications. This multi-faceted approach positions ENGIE as a comprehensive renewable energy provider rather than a single-technology specialist.

3. E.ON SE: German Utility’s Sustainable Biomass Integration

E.ON SE, one of Germany’s largest energy companies with annual revenue exceeding sixty-five billion dollars, has established significant biomass generation capacity as part of its broader renewable energy strategy. Headquartered in Essen, Germany, E.ON operates across European markets and has systematically expanded its renewable generation portfolio in response to Germany’s Energiewende energy transition policy.

The company’s biomass operations reflect sophisticated understanding of how this renewable resource complements other generation sources within modern electricity systems. E.ON operates biomass power plants that provide baseload generation and system stability services, filling the critical gap between intermittent renewable sources and dispatchable power that electricity grids require. This operational flexibility makes biomass generation particularly valuable during periods of low solar and wind output, when electricity demand peaks, or when grid stability requires rapid response.

E.ON has pioneered combined heat and power applications for biomass, capturing waste heat from electricity generation and distributing it through district heating networks serving urban residential and commercial customers. This cogeneration approach dramatically improves overall system efficiency, often achieving total energy utilization rates exceeding eighty percent compared to the thirty to forty percent efficiency typical of electricity-only generation. The economic and environmental benefits of combined heat and power have made this configuration standard for E.ON’s urban biomass installations.

The company has also invested in advanced emissions control technology that minimizes air quality impacts from biomass combustion. Modern biomass power plants operated by E.ON employ selective catalytic reduction for nitrogen oxide control, electrostatic precipitators or fabric filters for particulate matter capture, and sophisticated combustion control systems that optimize fuel burning while minimizing incomplete combustion products. These technologies ensure that biomass facilities meet stringent European air quality standards while generating renewable electricity and heat.

E.ON’s commitment to innovation extends to feedstock diversification, with the company exploring agricultural residues, energy crops, and waste wood as supplements or alternatives to traditional forest-based pellets. This research aims to reduce pressure on forest resources while creating new economic opportunities for agricultural communities and improving the carbon intensity of biomass generation by utilizing materials that might otherwise be waste products.

4. Raízen: Brazil’s Sugarcane Biomass Powerhouse

Raízen, a joint venture between Brazilian conglomerate Cosan and Shell, represents Latin America’s largest integrated energy company and one of the world’s most significant biomass electricity producers. While the company is renowned for producing more than two point two billion liters of sugarcane ethanol annually, its biomass power generation operations demonstrate impressive scale and environmental benefits that merit recognition among global biomass energy leaders.

The company generates approximately three thousand megawatts of installed electricity capacity from sugarcane bagasse, the fibrous residue remaining after juice extraction from sugarcane. This approach exemplifies the circular economy concept, transforming what would otherwise be a waste product into valuable renewable electricity. The sugarcane biomass used by Raízen powers its own ethanol production facilities while generating substantial surplus electricity that is sold to Brazil’s national grid, providing renewable power to millions of Brazilian homes and businesses.

What makes Raízen’s biomass operations particularly significant from an environmental perspective is the favorable carbon profile of sugarcane residues. Because sugarcane grows rapidly and captures carbon dioxide from the atmosphere during cultivation, using bagasse for electricity generation creates a closed carbon loop with very low net emissions. The complete lifecycle, from cultivation through processing and energy generation, achieves carbon intensity substantially lower than fossil fuel alternatives, positioning sugarcane biomass as one of the most sustainable bioenergy pathways available.

Raízen has also demonstrated leadership in second-generation biofuel technology by partnering with Iogen Corporation to build a commercial cellulosic ethanol facility that converts bagasse and sugarcane straw into additional transportation fuel. This integration of first-generation ethanol production, biomass electricity generation, and advanced biofuel manufacturing from the same feedstock represents sophisticated optimization that extracts maximum value while minimizing waste and environmental impact.

The company’s renewable energy operations extend beyond electricity generation to encompass biogas production from vinasse and other organic waste streams generated during ethanol production. These biogas facilities capture methane that would otherwise escape to the atmosphere while producing additional renewable energy, demonstrating comprehensive resource utilization. Raízen’s integrated approach to sugarcane biorefining has established a model for agricultural biomass operations that other companies and countries increasingly study and emulate.

5. RWE: German Energy Leader’s Biomass Conversion

RWE, headquartered in Essen, Germany, ranks among Europe’s largest electricity producers and has developed substantial biomass generation capacity as part of its renewable energy transition. The company operates biomass power plants across multiple European countries and has actively converted coal facilities to biomass operation, demonstrating the technical feasibility of repurposing existing infrastructure for renewable generation.

RWE’s biomass strategy emphasizes co-firing arrangements where wood pellets or other biomass fuels are burned alongside coal in existing power stations. This approach provides several advantages including lower capital costs compared to building dedicated biomass facilities, gradual transition that maintains grid reliability during the coal phase-out, and operational flexibility to adjust fuel ratios based on economics and policy considerations. The company has successfully demonstrated co-firing rates exceeding fifty percent biomass in several facilities, with some units transitioning to one hundred percent biomass operation.

The company has invested substantially in biomass supply chain infrastructure including specialized handling equipment for wood pellets, storage facilities that manage moisture content and spontaneous combustion risks, and long-term fuel supply contracts with major pellet producers including Drax, Enviva, and Graanul Invest. This supply chain investment reflects RWE’s recognition that reliable biomass generation requires secure access to sustainably sourced fuel at predictable costs, particularly given the substantial volumes required for utility-scale power generation.

RWE has also pioneered biomass sustainability certification within the power generation sector, working with industry organizations to develop and implement verification systems that confirm sustainable forest management, measure lifecycle carbon emissions, and demonstrate compliance with European Union renewable energy directives. The company maintains comprehensive tracking systems that document the origin and chain of custody for biomass fuel, responding to stakeholder concerns about the environmental impacts of industrial-scale wood pellet consumption.

Looking forward, RWE continues evaluating opportunities to expand biomass generation capacity through additional conversions of coal facilities, new combined heat and power installations, and potential integration of carbon capture technology. The company views biomass as a transitional technology that provides dispatchable renewable generation during the period when electricity systems require backup for solar and wind but before alternative technologies such as long-duration energy storage or green hydrogen become economically viable at scale.

6. Enviva: Global Wood Pellet Supply Leader

Enviva, headquartered in Bethesda, Maryland, stands as the world’s largest producer of wood pellets for industrial-scale biomass energy generation. While Enviva itself does not operate power plants, the company’s role as the primary fuel supplier to major biomass electricity producers worldwide makes it an indispensable participant in the global biomass energy ecosystem. The company operates ten wood pellet manufacturing facilities across the Southeastern United States, with combined annual production capacity exceeding six point two million tonnes.

Enviva’s business model focuses on long-term take-or-pay contracts with utility companies in the United Kingdom, European Union, Japan, and South Korea that have converted coal power plants to biomass operation or built new biomass facilities. These contracts, often spanning ten to twenty years, provide Enviva with predictable revenue while giving utility customers certainty regarding fuel supply and pricing. The company ships wood pellets through deep-water marine terminals in Virginia and Mississippi, with sophisticated logistics operations that coordinate forest harvesting, truck transportation, pellet manufacturing, rail delivery, and vessel loading.

The company sources wood fiber primarily from working forests in the Southeastern United States, utilizing materials including sawmill residues, thinnings from forest management operations, and low-grade roundwood unsuitable for higher-value lumber production. Enviva maintains that its sourcing practices support sustainable forest management by creating markets for low-value wood that encourages landowners to maintain forests rather than converting land to agriculture or development. The company has implemented comprehensive sustainability policies and obtains third-party certification for its operations.

However, Enviva has faced significant challenges. In late 2023, the company experienced catastrophic financial losses exceeding two hundred fifty million dollars, leading to CEO replacement and questions about the company’s viability. Industry analysts attributed these difficulties to miscalculations regarding wood procurement costs, operational challenges at manufacturing facilities, and the capital-intensive nature of pellet production. Despite these setbacks, Enviva continued operations through 2024 and into 2026, supplying essential fuel to biomass power plants globally, though the company’s long-term trajectory remains subject to ongoing financial restructuring.

The company’s experience highlights broader challenges facing the biomass energy sector including the economics of fuel production and transportation, the importance of sustainable sourcing practices that withstand environmental scrutiny, and the complex relationship between forest conservation, working forest management, and industrial wood pellet demand. Enviva’s resolution of its financial challenges and evolution of its business model will significantly influence the availability and economics of wood pellets for power generation globally.

7. Ameresco: Integrated Renewable Energy Solutions

Ameresco, headquartered in Framingham, Massachusetts, represents a different model within the biomass energy sector, focusing on designing, building, and operating renewable energy projects for institutional, commercial, and government customers. The company’s biomass operations include both power-only and combined heat and power installations that serve hospitals, universities, military bases, and municipal facilities seeking to reduce fossil fuel consumption and greenhouse gas emissions.

Ameresco’s approach emphasizes customized solutions tailored to specific customer requirements and local feedstock availability. The company has developed biomass facilities that burn wood chips from forest management operations, agricultural residues including corn stover and wheat straw, biogas captured from landfills and wastewater treatment plants, and municipal solid waste diverted from landfills. This feedstock flexibility allows Ameresco to optimize projects based on regional fuel availability, customer sustainability goals, and economic considerations.

The company’s business model typically involves energy-as-a-service arrangements where Ameresco finances, builds, owns, and operates biomass facilities while selling electricity, steam, or hot water to customers under long-term contracts. This approach removes capital barriers that might otherwise prevent institutions from adopting biomass energy while transferring operational risk and fuel procurement responsibilities to Ameresco. The company’s expertise in project development, financing structuring, and long-term operations management has enabled successful deployment of biomass solutions across diverse applications and geographies.

Ameresco has demonstrated particular success with biogas projects that capture methane from organic decomposition and convert it to electricity or pipeline-quality renewable natural gas. The company operates numerous landfill gas-to-energy facilities and agricultural biogas projects that address waste management challenges while generating renewable energy. These projects often deliver multiple benefits including methane emission reduction, odor control, renewable electricity generation, and production of digestate that serves as organic fertilizer.

The company continues expanding its renewable energy portfolio beyond biomass to include solar, wind, energy storage, and energy efficiency services, positioning itself as a comprehensive clean energy provider. However, biomass remains a core capability, particularly for customers requiring reliable baseload renewable power or seeking to utilize local organic waste streams. Ameresco’s project development pipeline includes ongoing biomass installations that will contribute to the company’s growth through 2026 and beyond.

8. EnviTec Biogas: European Biogas Technology Leader

EnviTec Biogas, headquartered in Lohne, Germany, specializes in biogas technology and has established itself as Europe’s leading producer of biogas-derived electricity and heat. The company designs, constructs, and operates biogas plants that convert agricultural residues, food waste, and energy crops into renewable gas through anaerobic digestion, a biological process fundamentally different from the direct combustion used in wood-fired biomass facilities.

EnviTec operates its own biogas plants throughout Europe with combined installed electrical capacity measured in tens of megawatts, generating renewable electricity while producing digestate that serves as organic fertilizer. The company also provides engineering, procurement, and construction services for third-party biogas projects, offering comprehensive solutions from feasibility assessment through commissioning and long-term operations and maintenance support. This dual model combines revenue from electricity sales with engineering services income, providing diversified earnings streams.

The company’s biogas technology offers several advantages compared to traditional biomass combustion. Anaerobic digestion efficiently converts diverse organic feedstocks including materials too wet for combustion into biogas with methane content typically ranging from fifty to seventy percent. The process operates at relatively low temperatures, produces no combustion emissions, and generates digestate that returns nutrients to agricultural land, creating a closed nutrient loop that supports sustainable farming. When biogas is upgraded to remove carbon dioxide and trace contaminants, it becomes biomethane that can be injected into natural gas pipelines, providing renewable gas for heating, industrial processes, or vehicle fuel.

EnviTec has pioneered flexible biogas generation that responds to electricity market signals, operating digesters at variable rates to increase biogas production and electricity generation during peak demand periods when power prices are highest. This demand-responsive operation maximizes economic returns while providing grid services similar to those offered by conventional power plants. The company has also developed biogas upgrading facilities that produce biomethane meeting stringent pipeline quality specifications for injection into European natural gas networks.

The company continues expanding its biogas operations across multiple European countries including Germany, Italy, the United Kingdom, Czech Republic, France, and others. EnviTec has also begun international expansion with projects in the United States, China, and elsewhere, sharing European biogas expertise with markets increasingly interested in renewable gas technology. The company’s success demonstrates the significant potential for agricultural-based biomass energy that complements forest-based approaches to bioenergy production.

9. Graanul Invest: Europe’s Wood Pellet Production Leader

Graanul Invest, headquartered in Tallinn, Estonia, ranks as Europe’s largest producer of wood pellets and one of the most significant global players in industrial pellet manufacturing. Operating twelve modern pellet plants across Estonia, Latvia, Lithuania, and the United States, the company produces approximately two point seven million tonnes of wood pellets annually, with recent expansions targeting over four million tonnes by 2026.

The company supplies primarily industrial customers including European power plants operated by Drax, ENGIE, RWE, and others that have converted coal facilities to biomass generation or built dedicated biomass power stations. Approximately ninety-eight percent of Graanul Invest’s production consists of industrial-grade pellets exported from the Baltic states to the United Kingdom, Denmark, Netherlands, and other European markets where biomass energy has achieved significant scale. The remaining production comprises premium residential pellets certified to DINplus and ENplus A1 standards for home heating applications.

Graanul Invest’s operations emphasize sustainability and vertical integration. The company sources wood fiber exclusively from sawmill residues, wood processing waste, and low-quality roundwood unsuitable for lumber production, avoiding any competition with higher-value wood product markets. All pellet plants incorporate combined heat and power systems that burn bark and other process residues to generate the thermal energy required for pellet drying and compression, dramatically reducing fossil fuel consumption and improving overall carbon footprint. Some facilities also export surplus renewable electricity to regional grids.

The company has invested substantially in production technology including digital monitoring systems that track material flows and optimize processes, three-dimensional scanning of incoming raw materials for accurate inventory management and quality control, and automated handling systems that minimize labor requirements while ensuring consistent pellet quality. These technological advantages allow Graanul Invest to maintain high production volumes while competing effectively on cost, quality, and reliability.

Graanul Invest commissioned a new five hundred thousand tonne capacity facility in Estonia in mid-2024, increasing its total production footprint by fifteen percent and supporting continued export growth to Northern European biomass power markets. The company has also acquired its own bulk carrier vessel, providing control over shipping logistics and reducing dependence on third-party maritime services. This combination of production expansion, vertical integration, and logistics control positions Graanul Invest for continued growth as European demand for sustainable wood pellets increases.

10. Ørsted: Danish Energy Company’s Biomass Evolution

Ørsted, headquartered in Fredericia, Denmark, represents one of Europe’s most significant renewable energy companies with operations spanning offshore wind, onshore wind, solar, and historically, biomass power generation. While the company has increasingly focused investment on offshore wind development, Ørsted continues operating biomass combined heat and power plants in Denmark that provide important contributions to the country’s renewable energy supply.

The company’s biomass operations utilize wood pellets, wood chips, and straw in combined heat and power plants that serve Danish district heating networks. These facilities exemplify the high-efficiency cogeneration that characterizes Scandinavian energy systems, achieving total energy utilization rates approaching ninety percent by capturing waste heat for residential and commercial heating. This integration of electricity generation with thermal energy distribution represents best practice for biomass energy applications in cold climates where heating demand is substantial.

Ørsted has also conducted pioneering work on biomass sustainability and carbon accounting. The company developed comprehensive methodologies for evaluating lifecycle greenhouse gas emissions from biomass operations, considering factors including forest carbon stock changes, emissions from harvesting and processing, transportation impacts, and alternatives that would occur if biomass was not utilized for energy. This analytical work has informed international debates regarding biomass sustainability and appropriate carbon accounting frameworks for bioenergy.

However, Ørsted’s biomass strategy has evolved significantly in recent years as the company refocused its capital allocation toward offshore wind, which it views as offering superior growth potential and environmental benefits. The company has divested some biomass assets, reduced new biomass investments, and emphasized that biomass serves as a transitional technology rather than a long-term cornerstone of renewable energy strategy. Despite this strategic shift, Ørsted’s existing biomass facilities continue contributing renewable power and heat to Danish energy systems while the country develops additional renewable generation and energy storage capacity.

The company’s experience and evolving strategy illustrate broader debates within the renewable energy sector regarding biomass’s appropriate role. While biomass provides dispatchable renewable generation that complements intermittent wind and solar, questions persist regarding long-term sustainability, competition for forest resources, lifecycle carbon impacts, and opportunity costs compared to alternative renewable technologies. Ørsted’s transition away from biomass toward offshore wind reflects one major energy company’s assessment of these trade-offs and its vision for the optimal renewable energy portfolio.

The Future of Biomass Energy Production

Biomass energy production in 2026 stands at a critical juncture between established operations that demonstrate technical and commercial viability and emerging challenges that will shape the industry’s long-term trajectory. The ten companies profiled represent diverse approaches to biomass energy, from utility-scale wood pellet combustion producing hundreds of megawatts of dispatchable renewable electricity to agricultural biogas operations that convert farm waste into renewable power and heat while supporting sustainable farming practices.

Several key trends are shaping biomass energy’s evolution. Carbon capture and storage technology, pioneered by companies like Drax, promises to transform biomass from a low-carbon energy source into a carbon-negative one, actively removing greenhouse gases from the atmosphere while generating electricity. This development could fundamentally alter biomass’s role in climate mitigation strategies, positioning it as one of the few scalable carbon removal technologies available. However, realizing this potential requires continued technology development, supportive policy frameworks, and acceptance of carbon capture infrastructure.

Sustainability standards and certification systems continue evolving in response to scientific research and stakeholder concerns about biomass’s environmental impacts. Leading companies have implemented comprehensive sourcing policies, third-party verification, and transparent reporting to demonstrate responsible practices. Industry organizations have developed certification programs that assess forest management, measure lifecycle emissions, and verify compliance with regulatory requirements. These systems will become increasingly sophisticated and stringent as biomass operations scale and face closer scrutiny from environmental advocates and policymakers.

The economics of biomass energy remain subject to multiple variables including wood pellet prices influenced by global supply and demand dynamics, policy support including renewable energy subsidies and carbon pricing that improve biomass competitiveness against fossil fuels, and competition from alternative renewable technologies whose costs continue declining. Companies that achieve low-cost sustainable fuel supply, operate high-efficiency conversion technology, and maintain operational flexibility will be best positioned for success regardless of how these factors evolve.

The ultimate scale and duration of biomass energy’s contribution to global decarbonization will depend on resolving ongoing debates regarding sustainable sourcing limits, appropriate carbon accounting methodologies, and biomass’s role relative to expanding solar, wind, and energy storage deployment. The companies leading biomass energy production in 2026 are actively participating in these discussions while continuing to operate facilities that provide renewable electricity supporting the energy transition today. Their success in demonstrating sustainable, effective, and economically viable biomass energy will determine whether this resource contributes modestly or substantially to achieving global climate goals.