Top 10 Hydrogen Vehicle Startups In 2026

To understand why hydrogen vehicles are attracting so much attention in India specifically, it helps to first understand the limitation that has quietly constrained the battery electric vehicle revolution in one of the country’s most important transport segments. Battery electric technology is genuinely transformative for personal cars, two-wheelers, and urban delivery vehicles.

But when you scale the vehicle up — a 40-tonne truck, a 200-kilometre intercity bus, a mining dumper, a railway locomotive — the physics start working against you. Batteries are heavy. The bigger the vehicle and the longer the route, the heavier and more expensive the battery pack required, until at some point you are carrying so much battery weight that your payload capacity or passenger capacity is meaningfully compromised. Charging infrastructure for heavy vehicles also requires significant grid investment.

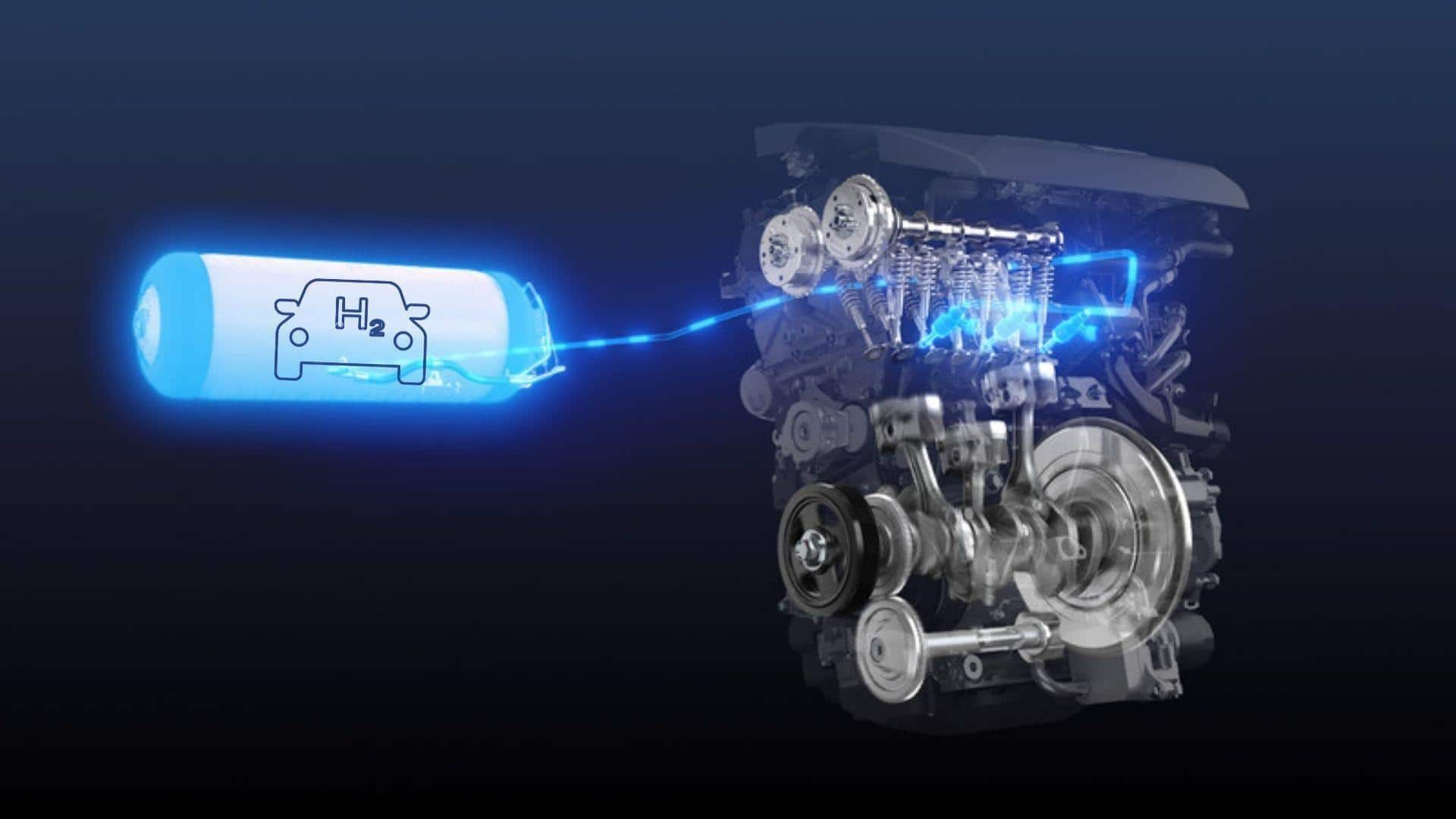

Hydrogen fuel cell vehicles sidestep this problem with a different energy architecture. Instead of storing energy chemically in a battery pack, they store it in the form of compressed hydrogen, which is energy-dense by weight even if not by volume. The fuel cell converts that hydrogen to electricity on demand, powering electric motors that drive the wheels. The only tailpipe emission is water vapour. Refuelling takes minutes rather than hours. And critically, the more you scale up the vehicle, the more competitive hydrogen becomes relative to batteries — which is precisely why the global automotive and transport industry is pursuing fuel cell technology most aggressively in the heavy-duty segment.

India’s hydrogen vehicle ecosystem in 2026 is at an early but genuinely consequential stage. The honest picture is that this is not yet a landscape of dozens of well-funded startups shipping commercial products. It is a more cautious and careful ecosystem of deep engineering organisations, forward-thinking OEMs, and enabling technology companies that are jointly constructing the technical and commercial foundations from which a hydrogen vehicle industry can grow. The following ten companies represent the most credible and active participants in that work.

1. Tata Motors

Tata Motors is India’s largest commercial vehicle manufacturer and by any measure the most operationally advanced organisation in the country when it comes to actually putting hydrogen fuel cell vehicles on Indian roads. Its hydrogen fuel cell bus programme has moved beyond concept demonstration into structured pilot deployments — running hydrogen buses in collaboration with Indian Oil Corporation to evaluate real-world performance in Indian traffic and climate conditions. What makes Tata Motors’ hydrogen vehicle work particularly significant is the institutional commitment behind it.

This is not a research department exploring options; it is a product organisation making engineering investments and building supplier relationships in anticipation of commercial procurement. In 2026, Tata’s hydrogen buses represent the clearest proof point in India that a hydrogen fuel cell commercial vehicle can actually operate, be maintained, and deliver reliable service in Indian conditions.

Vehicle focus: Hydrogen fuel cell buses for urban public transport, with structured pilot programmes across select Indian cities.

2. Ashok Leyland

Ashok Leyland, the Hinduja Group’s commercial vehicle flagship and India’s second-largest truck and bus manufacturer, is running its hydrogen vehicle programme in parallel with Tata Motors and has deliberately pursued a slightly differentiated technical and commercial pathway. Where Tata has developed its fuel cell powertrain through close integration with the broader Tata Group’s hydrogen ecosystem, Ashok Leyland has been more open to international technology partnerships — working with overseas fuel cell stack suppliers to accelerate its development timeline while simultaneously building internal engineering capability that will reduce this foreign dependency over time.

The company’s hydrogen bus trials have involved partnerships with several state transport undertakings across India, generating operational data that is feeding directly back into vehicle refinement. Ashok Leyland’s manufacturing base in Tamil Nadu and its strong relationship with South Indian state governments make it well-positioned to secure early commercial orders if state-level hydrogen bus procurement programmes materialise in the near term.

Vehicle focus: Hydrogen fuel cell buses for intercity and urban transit, with active pilot deployments and international technology partnerships.

3. KPIT Technologies

Understanding KPIT’s role in hydrogen vehicles requires appreciating that a hydrogen fuel cell vehicle is, at its core, a highly complex software-defined machine. The fuel cell system, the high-voltage battery buffer, the electric drive motors, the hydrogen storage and pressure regulation systems, and the vehicle’s safety architecture must all be coordinated in real time by sophisticated embedded software.

This software — called the Vehicle Control Unit and the Fuel Cell Management System — is what KPIT Technologies specialises in developing, and its expertise in this domain is genuinely rare in India. Based in Pune with deep roots in automotive software engineering, KPIT works with both Indian OEMs and global vehicle manufacturers on the software architecture, powertrain integration, and safety validation frameworks that convert a fuel cell stack into a road-legal, functional vehicle. The company’s contribution to the hydrogen vehicle ecosystem is less visible than a shiny bus prototype but arguably more foundational, because without the software layer, the hardware cannot perform safely or efficiently.

Vehicle focus: Fuel cell vehicle software, powertrain control systems, and systems integration for automotive OEM customers developing hydrogen vehicles.

4. Mahindra & Mahindra

Mahindra & Mahindra approaches hydrogen vehicles from a set of use cases that are distinct from those driving Tata Motors and Ashok Leyland, and this differentiation makes the company’s contribution to the ecosystem genuinely additive rather than duplicative. While the other OEMs focus on buses and heavy trucks, Mahindra has been exploring hydrogen fuel cells for agricultural tractors and light-to-medium commercial vehicles — applications where the group’s existing product strengths and distribution infrastructure create a natural commercialisation pathway.

The tractor use case is particularly interesting in the Indian context. Agricultural tractors in India operate intensively during harvest seasons, often in remote areas without reliable charging infrastructure, and require sustained high-torque output over many continuous hours. These operating characteristics make fuel cells a potentially better fit than batteries for this application, and Mahindra’s exploration of hydrogen tractors is therefore not speculative diversification but a reasoned technical analysis of where the technology’s advantages are strongest.

Vehicle focus: Hydrogen fuel cell tractors and light commercial vehicles, with technology exploration across agricultural and off-highway applications.

5. H2e Power Systems

H2e Power Systems is the startup on this list that is doing the most specifically focused deep-engineering work on fuel cell powertrains for Indian vehicles, and it deserves its place here for that singular commitment. Founded in Pune — a city whose automotive engineering ecosystem is among the richest in Asia — H2e has been developing PEM fuel cell systems that are specifically calibrated for the thermal management challenges, humidity variations, and operational demands of Indian vehicle deployments.

The fundamental engineering insight driving H2e’s work is that a fuel cell system optimised for a German city bus operating in 15-degree ambient temperatures cannot simply be installed in an Indian vehicle operating at 45 degrees during a North Indian summer without significant re-engineering of the cooling system, the humidification architecture, and the stack’s operating protocols. H2e is doing that re-engineering from the ground up — a less glamorous task than designing a vehicle from scratch, but one whose quality will determine whether hydrogen vehicles actually achieve the reliability and longevity in Indian fleets that makes them economically viable.

Vehicle focus: India-adapted PEM fuel cell systems for commercial vehicle powertrains, with engineering specifically focused on Indian climatic and operational conditions.

6. Atmos Energy Systems

Storing hydrogen on a vehicle at pressures of 350 to 700 bar — the pressure ranges required to pack meaningful energy density into a tank of reasonable size — is one of the less-discussed but genuinely difficult engineering challenges in hydrogen vehicle development. The cylinders used for this purpose, called type-4 composite cylinders, are made from carbon-fibre-reinforced polymer wound over a polymer liner, and they must meet extraordinarily stringent safety standards because a rupture at those pressures would be catastrophic.

Atmos Energy Systems is an Indian startup working specifically on high-pressure composite hydrogen storage systems — both the cylinders themselves and the integrated valve, regulator, and pressure monitoring assemblies that make those cylinders safe to operate in a vehicle environment. India currently has essentially no domestic manufacturing capability for high-quality type-4 hydrogen cylinders, meaning every hydrogen vehicle deployed in India today uses imported storage systems. Atmos is attempting to change that, with implications not just for vehicle cost but for India’s long-term strategic self-sufficiency in hydrogen vehicle technology.

Vehicle focus: High-pressure composite hydrogen storage cylinders and integrated storage systems for vehicle applications.

7. Log 9 Materials

The performance ceiling of a hydrogen fuel cell vehicle is, at its most fundamental level, determined by the quality of the membrane electrode assembly at the heart of each fuel cell — a multi-layer electrochemical structure where the actual energy conversion happens. The catalyst in that assembly is what enables the hydrogen oxidation and oxygen reduction reactions, and improving its efficiency, durability, and cost is one of the most active areas of research in the global hydrogen vehicle industry.

Log 9 Materials, whose scientific foundation in advanced nanomaterials and electrochemistry is among the deepest of any Indian startup, is working on the materials science challenges that underpin next-generation fuel cell performance.

The company’s work on nano-structured carbon materials, graphene derivatives, and non-platinum catalysts speaks directly to the question of how Indian fuel cell vehicles will eventually achieve cost parity with diesel alternatives — because the platinum catalyst is currently one of the most significant cost components in a fuel cell stack, and reducing it without sacrificing performance is worth billions of dollars to the global automotive industry. In 2026, Log 9’s commercial revenue comes primarily from its aluminium-air battery products, but its fuel cell materials research is a parallel track whose long-term significance for hydrogen vehicles is substantial.

Vehicle focus: Advanced electrode materials and catalyst research for fuel cell stacks, addressing fundamental cost and performance challenges in hydrogen vehicle powertrains.

8. Titagarh Rail Systems

Hydrogen vehicles are not limited to the road network, and Titagarh Rail Systems — formerly Titagarh Wagons, a Kolkata-headquartered rolling stock manufacturer listed on Indian exchanges — is the most credible Indian company working on hydrogen-powered rail vehicles. The company has been actively developing hydrogen fuel cell rail cars in response to the Indian Railways’ interest in decarbonising its non-electrified network.

India has approximately 40 percent of its railway network still running on diesel traction, and converting these lines to overhead electric catenary is expensive and time-consuming. Hydrogen fuel cell trains — which carry their own fuel and generate electricity on board without requiring catenary infrastructure — offer a potentially faster and more economical decarbonisation pathway for these routes. Titagarh’s engineering capabilities in rail vehicle manufacturing combined with its investment in fuel cell integration make it a genuinely important participant in the hydrogen vehicle ecosystem from the rail perspective, a segment that is often overlooked in road-transport-dominated discussions of the topic.

Vehicle focus: Hydrogen fuel cell rail vehicles for non-electrified railway lines, targeting the decarbonisation of India’s diesel traction network.

9. Gensol Engineering

Gensol Engineering has built its primary reputation as a solar energy engineering and EPC company, but its hydrogen vehicle interests are specifically focused on an aspect of the hydrogen vehicle ecosystem that does not receive enough attention: refuelling infrastructure. A hydrogen vehicle is only as useful as the network of hydrogen refuelling stations it can access, and India in 2026 has essentially no public hydrogen refuelling network outside of a handful of demonstration stations. Gensol has been developing integrated solar-to-hydrogen refuelling station designs — modular facilities where on-site solar generation powers an electrolyzer that produces hydrogen, which is then compressed, stored, and dispensed to vehicles.

This distributed, renewable-powered refuelling model addresses one of the fundamental chicken-and-egg problems of hydrogen vehicle adoption: vehicle manufacturers hesitate to scale production without refuelling infrastructure, and infrastructure investors hesitate to build without vehicle volumes. Gensol’s integrated station designs, which bundle generation, production, and dispensing into a deployable unit, offer a practical way to initiate that infrastructure buildout at manageable capital cost.

Vehicle focus: Integrated solar-powered hydrogen refuelling station design and deployment, enabling the infrastructure layer that hydrogen vehicle adoption requires.

10. Caspian Automation and Controls

Every hydrogen vehicle refuelling station and maintenance facility requires a sophisticated nervous system of sensors, leak detectors, pressure monitors, and automated safety interlocks to operate safely — and Caspian Automation and Controls, the Hyderabad-based industrial safety systems startup, is building exactly those systems with an orientation toward hydrogen’s specific safety characteristics. Hydrogen’s physical properties make it simultaneously a wonderful fuel and a challenging one to manage safely: it is the smallest molecule in existence and leaks through gaps that contain larger molecules; it ignites over a very wide concentration range in air; and its flame is nearly invisible in daylight.

The safety technology that manages these risks in a vehicle refuelling environment — including fast-response hydrogen sensors, automated emergency shutdown systems, and continuous atmosphere monitoring — is specialised, important, and currently imported almost entirely from overseas suppliers. Caspian’s work on domestically developed hydrogen safety and monitoring technology is therefore both a commercial opportunity and a strategic necessity for an Indian hydrogen vehicle industry that cannot sustainably depend on foreign sourcing for safety-critical components.

Vehicle focus: Hydrogen safety systems, leak detection sensors, and automated safety controls specifically for vehicle refuelling and maintenance infrastructure.

The Ecosystem Logic Behind These Ten Companies

What these ten companies collectively reveal about India’s hydrogen vehicle industry is that it is being constructed through a deliberate division of technical labour rather than through a winner-take-all race between competing platforms. Tata Motors and Ashok Leyland are proving that hydrogen vehicles can work in Indian conditions.

KPIT is building the software layer that makes them safe and efficient. H2e is solving the climate adaptation problem. Atmos is addressing the storage supply chain gap. Log 9 is working on the fundamental electrochemistry that will determine long-term cost trajectories. Titagarh is extending the hydrogen vehicle concept beyond roads to rails. Gensol is building the refuelling infrastructure that makes vehicles practically usable. And Caspian is ensuring that the safety systems protecting people from hydrogen’s physical hazards are developed domestically rather than imported.

This kind of ecosystem-level thinking — where different organisations tackle adjacent, complementary problems — is exactly how mature technology industries develop, and recognising it helps explain why the absence of a single dominant Indian hydrogen vehicle startup is not a weakness of the ecosystem but rather a sign that the problem is being approached with appropriate sophistication.

The timeline to commercial scale for hydrogen vehicles in India is genuinely uncertain. The cost of green hydrogen needs to fall further. Refuelling infrastructure needs to be built before it can be used, and used before it can be justified economically. And fuel cell stack costs need to continue their trajectory downward before hydrogen buses are cost-competitive with diesel on a total cost of ownership basis without subsidy.

Most credible analyses suggest that the heavy commercial vehicle segment reaches this cost crossover point sometime between 2028 and 2035. The work being done by the companies on this list right now is exactly what determines whether India is a buyer of foreign hydrogen vehicle technology when that moment arrives, or whether it has built enough domestic capability to be a maker.

Conclusion

India’s hydrogen vehicle startup and technology ecosystem in 2026 is small, serious, and working on exactly the right problems. The ten organisations on this list span the full width of what needs to be built — from vehicle powertrains and onboard storage to refuelling infrastructure and safety systems — and each brings a distinct technical contribution that the others cannot replicate. The hydrogen vehicle industry globally is still in its formative decade, and India’s window to build a meaningful domestic position in this technology is open right now. These are the companies building through it.