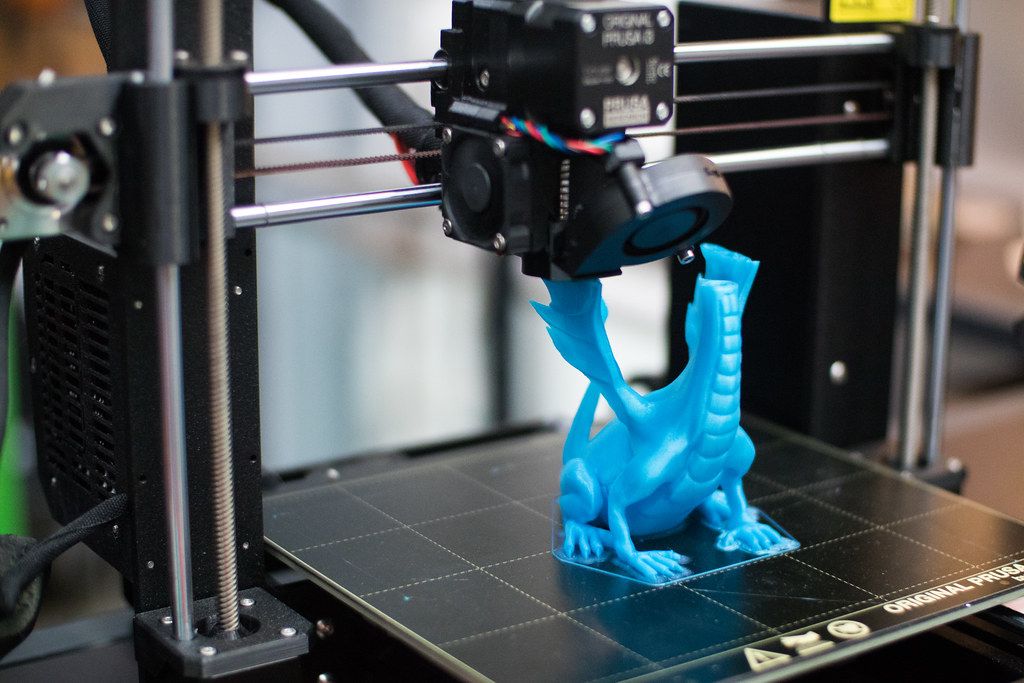

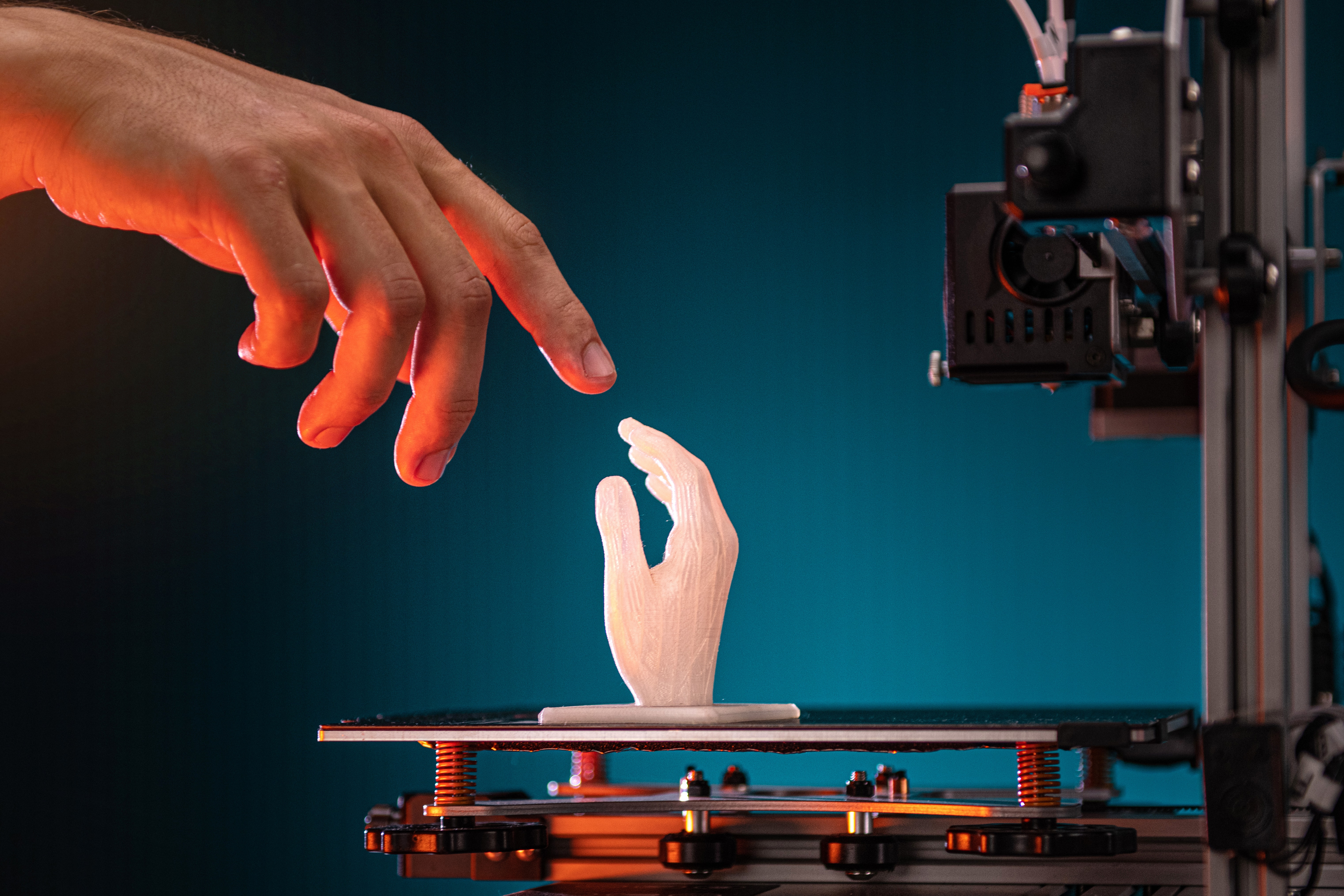

Top 10 3D Printing Manufacturers In 2026

Additive manufacturing (AM), commonly known as 3D printing, has evolved from a niche prototyping tool into a mainstream production technology by 2026. In recent years, the industry has shifted from prototyping to production as companies seek more agile supply chains and faster design iteration. This transition is driving a digital, distributed, and resilient manufacturing model across sectors like aerospace, healthcare, automotive, and consumer goods. Globally, the 3D printing market has been expanding at double-digit rates (over 20% CAGR), reaching an estimated $25–30 billion size by mid-decade.

Below, we present an exhaustive analysis of the top 10 additive manufacturing companies in 2026, ranked by a combination of revenue, technological innovation, and market influence. Each profile covers the company’s background, key 3D printing technologies, major industries served, recent developments, and its relevance to the Indian market.

1. Stratasys Ltd. – Polymer 3D Printing Pioneer and Market Leader

Overview: Stratasys is widely regarded as a founding pioneer of the 3D printing industry and remains a market leader in 2026. Founded in 1989 (dual-headquartered in Minnesota, USA and Rehovot, Israel), Stratasys was co-founded by Scott Crump – the inventor of Fused Deposition Modeling (FDM) technology. Over three decades, the company has built a broad portfolio of polymer 3D printing solutions, including FDM (thermoplastic extrusion), the PolyJet material jetting process (originating from Stratasys’s 2012 merger with Objet Ltd.), and more recently SLA and powder-bed technologies (via strategic acquisitions).

Stratasys’s portfolio ranges from desktop prototyping units to large industrial systems, supported by its proprietary software (GrabCAD Print) and a large library of materials. Notably, Stratasys remains the world’s largest polymer 3D printing company by revenue – on the order of $600–650 million annual revenue in recent years – giving it a commanding presence in the AM market.

Technologies and Innovations: Stratasys’s core technologies include its patented FDM™ printers (used for engineering-grade thermoplastics like ABS, polycarbonate, ULTEM™ etc.) and PolyJet™ printers (which jet photopolymer resins for high-detail, multi-material parts). The company continues to innovate in materials – for example, it acquired the Covestro AM materials business in 2023, expanding its range of high-performance photopolymers and thermoplastics. Stratasys also introduced new technologies such as SAF (Selective Absorption Fusion) for production-grade polymer sintering, and it operates a software ecosystem (GrabCAD and Insight) to streamline workflows. By integrating hardware, materials, and software, the company’s strategy is to offer end-to-end solutions that ensure reliability and repeatability for industrial use.

Market Influence and Sectors: With over 30 years in the industry, Stratasys has an enormous installed base and brand recognition. It serves a wide range of sectors – particularly aerospace, automotive, healthcare, and consumer products. In aerospace and defense, Stratasys’s high-performance FDM machines (capable of printing certified aircraft-grade plastics) are used to produce lightweight flight parts, ducting, and tooling for companies like Boeing and Lockheed.

The company has partnered with top aerospace/defense firms to qualify materials for flight-critical uses. In healthcare, Stratasys’s PolyJet technology is prized for its fine resolution and multi-material capability – enabling realistic surgical guides, medical models, and custom anatomical replicas. Its printers are also widely used in digital dentistry (e.g. for orthodontic models and surgical planning). In the automotive sector, Stratasys machines produce functional prototypes, jigs and fixtures for assembly, and even some end-use interior components for customization. Consumer products and electronics companies rely on Stratasys for rapid prototyping of new designs and short-run production without tooling.

Financials and Recent Developments: Stratasys has undergone significant strategic moves in the mid-2020s. In 2024, the company faced a challenging market environment with softened capital spending; it reported full-year 2024 revenue of $572.5 million (an 8.8% drop from 2023’s $627.6M). Despite the revenue dip, Stratasys improved gross margins to ~45% by focusing on higher-value applications and cost optimizations. The company has actively pursued industry consolidation: in 2023 it announced a proposed merger with Desktop Metal (to create a $1.8B combined company), aiming to blend Stratasys’s polymer leadership with Desktop Metal’s innovations in metals.

However, Stratasys shareholders ultimately voted down the Desktop Metal merger in Sept 2023 amid opposition. Stratasys then explored other strategic alternatives. (Notably, in a twist, Desktop Metal was later acquired by Nano Dimension in 2025 – see Desktop Metal section). Stratasys has since doubled down on its own strengths, focusing on “innovation and profitable growth” as an independent company. It divested non-core services (e.g. Stratasys Direct Manufacturing was partially spun off) and emphasized moving customers from prototyping to production-scale printing of end-use parts.

Looking ahead to 2026, Stratasys’s outlook is to “defend share while nudging customers from prototyping to production”, especially for high-mix, low-volume applications where digital manufacturing shines. The firm is also expanding in software (production management and MES tools) and sustainable manufacturing (promoting digital inventory to reduce waste). With its broad technology stack and deep application expertise, Stratasys remains a cornerstone of the 3D printing industry.

Indian Market Impact: In India, Stratasys is one of the most established AM suppliers. Through its Stratasys India office and reseller network, the company has provided industrial 3D printers to leading Indian organizations. For example, Hindustan Aeronautics Ltd (HAL) and the Indian Defence R&D Organization (DRDO) have explored Stratasys FDM printers for tooling and aerospace parts development. Indian automotive OEMs and suppliers use Stratasys systems for rapid prototyping of components and assembly jigs, reducing design cycles.

Healthcare startups and hospitals in India utilize Stratasys PolyJet printers to create patient-specific models for surgical planning and dental aligners. As India ramps up its AM adoption, Stratasys’s trusted technologies and local support presence position it to continue as a market leader in the region, catering to India’s growing needs in aerospace, defense, automotive, and healthcare applications.

2. 3D Systems Corporation – Diversified AM Portfolio and Healthcare Specialist

Overview: 3D Systems, founded in 1986 by Chuck Hull (the inventor of stereolithography), holds the distinction of being the world’s first 3D printing company and a continual innovator in the field. Headquartered in Rock Hill, South Carolina, 3D Systems has built a broad and diversified portfolio covering multiple 3D printing technologies – including stereolithography (SLA), selective laser sintering (SLS), direct metal printing (DMP laser metal), material jetting (MJP), and even bioprinting.

Over the years, the company expanded through numerous acquisitions (e.g. Z Corp for color jetting, DTM for SLS, Metalmatics for metal, etc.), giving it one of the most comprehensive offerings in the industry. In 2026, 3D Systems remains a top-tier AM manufacturer by revenue (on the order of ~$500+ million annually) and is known as a “one-stop shop” for additive solutions, including hardware, materials, and software.

Technologies and Products: 3D Systems’ technology breadth is unrivaled. It commercialized the first SLA printers in the late 1980s, and its modern SLA lineup (e.g. Figure 4 and SLA 750) offers high-speed, precision resin printing for industrial and dental uses. The company’s SLS machines (e.g. sPro and ProX series) are widely used for durable nylon parts. In metals, 3D Systems’ DMP (Direct Metal Printing) machines employ laser powder-bed fusion for complex metal components. It also developed MJP (MultiJet Printing) for casting patterns and detailed prototypes, and acquired polymer DLP technology (the Figure 4 platform) for fast, modular production.

Complementing the hardware, 3D Systems supplies a range of materials (photopolymer resins, nylon and elastomer powders, metal alloys, etc.) and its acclaimed 3D Sprint and 3Dexpert software for build preparation and design optimization. Notably, 3D Systems has a strong software and services component: it offers on-demand part manufacturing and previously owned popular 3D modeling software (Geomagic, Cimatron). After some restructuring, the company refocused on its core printer and materials business, selling off non-core software units in 2021–2022 to streamline operations.

Key Industries: 3D Systems is deeply entrenched in industrial and healthcare sectors. Its solutions are used in aerospace & defense for lightweight metal parts and complex assemblies – for instance, its DMP metal printers produce qualified aerospace components like fuel nozzles and satellite parts. In automotive and motorsports, 3D Systems SLA/SLS machines churn out functional prototypes, wind tunnel models, and jigs/fixtures. However, one of 3D Systems’ standout focuses is healthcare, which has become a high-growth, high-margin segment for the company.

The firm’s Healthcare division provides FDA-cleared solutions for medical and dental applications: surgeons use its printers for patient-specific anatomical models and surgical guides; its acquired NextDent portfolio offers 3D printing resins for dental appliances (crowns, dentures, aligners). 3D Systems has even ventured into bioprinting (regenerative medicine) by partnering on printing human tissues and organs. This strong presence in healthcare – including surgical planning software and even printed implants – gives 3D Systems a unique edge and stable revenue stream.

Strategy and Developments: Under CEO Jeff Graves (appointed 2020), 3D Systems has been executing a turnaround and refocus strategy. The company streamlined its operations to concentrate on core strengths in industrial and medical additive manufacturing, divesting ventures like on-demand parts services to reduce complexity. It has been sharpening its go-to-market approach by aligning solutions with specific high-value applications. For instance, 3D Systems is investing in application development centers to help customers move from prototyping to production with its machines. Despite its long history, 3D Systems has faced the challenge of inconsistent profitability. In 2023–24, macro headwinds impacted sales, with 2022 revenue around $530M and a slight decline into 2023.

To return to growth, 3D Systems made bold moves – including a bid in mid-2023 to merge with Stratasys (offering $27/share) as part of the industry’s consolidation wave. That proposal was not consummated, but it underscored 3D Systems’ intent to scale up. Instead, 3D Systems proceeded to acquire smaller niche players (e.g. bioprinting startup Volumetric and software firms) to augment its tech portfolio. By 2025, the company began seeing improved margins through cost cuts and higher materials attach rates.

Heading into 2026, 3D Systems’ vision is to leverage its broad technology suite to serve customers from prototyping through regulated, serial production. The firm emphasizes solutions in dental and medical manufacturing (where it has an installed base of thousands of printers in labs and hospitals), as well as production systems for aerospace and semiconductor industries. Its challenge and opportunity lie in driving more recurring revenue (materials, software, services) from its large installed base to stabilize growth.

Indian Market Impact: 3D Systems has a notable presence in India’s additive landscape through channel partners. Indian service bureaus and manufacturers have deployed 3D Systems SLA and SLS machines for high-precision prototyping – for example, in Bengaluru and Pune’s industrial clusters, 3D Systems printers are used to make automotive and electronics prototypes. In healthcare, some of India’s dental labs and hospitals utilize 3D Systems solutions (such as NextDent 5100 printers) to produce custom dental devices and anatomical models.

Additionally, 3D Systems’ metal DMP machines have been supplied to Indian research institutions and aerospace R&D centers for developing indigenous aerospace parts (aligning with the “Make in India” initiative for defense). With its end-to-end offerings, 3D Systems is positioned to support India’s push to build a domestic AM ecosystem, especially in medical tech and industrial manufacturing. As India’s market matures (projected 25%+ CAGR in AM adoption), 3D Systems’ longstanding expertise and local partnerships are likely to make it a key enabler of advanced manufacturing in the region.

3. EOS GmbH – Industrial Metal & Polymer AM Powerhouse

Overview: EOS (Electro-Optical Systems) is a privately-held German company that stands as a world leader in industrial 3D printing for both metals and polymers. Founded in 1989 by Dr. Hans Langer, EOS was an early pioneer of laser sintering technology in Europe. Over the decades, EOS has built an immense reputation for high-end additive manufacturing systems, particularly for demanding applications in aerospace, medical, and tooling.

The company’s headquarters in Krailling (near Munich) oversees a global operation – EOS has installed thousands of machines worldwide and, according to industry data, is the third-largest polymer AM company by revenue (after Stratasys and 3D Systems) and a top player in metal AM as well. EOS’s success has been driven by its focus on quality, reliability, and materials innovation, making it a trusted supplier to industrial customers. Although financials are not publicly disclosed (as a private firm), EOS’s annual revenue is estimated in the few hundreds of millions USD range, keeping it among the top-tier manufacturers globally.

Technology Portfolio: EOS’s flagship technology is laser powder bed fusion (LPBF) – using high-power lasers to fuse powdered material layer by layer. In polymers, EOS introduced one of the first SLS (Selective Laser Sintering) systems in the early 1990s and has remained the market leader in polymer laser sintering. Its polymer SLS machines (e.g. EOS P 396, P 500 series) are considered the gold standard for producing tough, production-grade nylon parts, with build volumes and automation features geared for manufacturing.

In metal 3D printing, EOS developed DMLS (Direct Metal Laser Sintering) technology – essentially the metal LPBF process. EOS’s metal printer lineup (e.g. EOS M 290, EOS M 400 series) is widely used for high-precision components in titanium, aluminum, nickel alloys, and more. They offer systems ranging from mid-size (M 290) to large-format, multi-laser platforms (M 400-4) for productivity. Beyond hardware, EOS provides a complete ecosystem: it produces its own certified materials (over 20 metal alloys and many polymers are qualified on EOS machines), process parameter sets for different applications, and software for job preparation and monitoring. EOS also has a specialized unit, AMCM (Additive Manufacturing Customized Machines), to build custom systems beyond standard specs for clients.

Industry Leadership and Applications: EOS has a dominant presence in aerospace and medical implant manufacturing. In aerospace, EOS metal printers are used to produce parts like fuel nozzles, turbine blades, and satellite components, where material performance and weight reduction are critical. The company works closely with aerospace OEMs and authorities to meet certification standards (e.g. EOS printed components are flying on commercial aircraft and space launch vehicles). In healthcare, EOS machines (especially the smaller EOS M 290) are heavily used for orthopedic implants and dental prosthetics – for instance, many orthopedic implant manufacturers use EOS titanium printing to create porous, patient-specific implants (hip cups, spinal cages) that encourage bone growth.

EOS’s polymer SLS technology also finds broad use in automotive (for functional prototyping and series parts), consumer products (e.g. eyewear frames, athletic equipment), and industrial tooling. Its systems are known for producing robust end-use parts; a classic example is how service bureaus worldwide rely on EOS SLS to manufacture thousands of production parts on demand, from drone components to sneaker soles.

Corporate Developments: EOS has remained family-owned (the Langer family) and kept a steady growth path focused on engineering excellence rather than mergers. It avoided the SPAC frenzy of early 2020s, maintaining financial stability. The company did, however, spawn or acquire complementary ventures: it owns Advanced Laser Materials (ALM) for materials and invested in software and quality tracking startups. In 2024, EOS emphasized sustainability and reducing material waste, launching initiatives to recycle unused powder and develop more eco-friendly materials.

EOS also faces rising competition in metal AM (e.g. from GE Additive and emerging Asian players), but it continues to innovate with features like multi-laser systems and process monitoring to stay ahead. According to industry reports, EOS remained the top metal AM machine seller as of 2024, and it was doubling down on R&D to maintain that lead. The company’s strategy involves providing end-to-end solutions – not just selling machines, but supporting customers with consulting, training, and service to ensure success in production. This has fostered strong loyalty among high-end users.

By 2026, EOS is likely exploring next-gen technologies (perhaps higher-power lasers, larger machines, or even new processes) to expand its market. Its AM industrialization theme aligns with global trends of 3D printing moving into factory lines. EOS’s long commitment to quality and innovation suggests it will remain a linchpin of the additive manufacturing industry’s continued growth.

Indian Market Impact: EOS has been instrumental in introducing metal 3D printing to India’s aerospace and medical sectors. EOS was among the first to partner with Indian service providers – for example, Wipro 3D (Bengaluru-based AM bureau) installed EOS metal printers to serve aerospace clients, including ISRO and HAL, for rocket engine and aircraft parts R&D. The Indian Space Research Organisation itself has used EOS systems in developing 3D printed engine components for satellites and launch vehicles.

In the medical field, a few Indian orthopedic implant startups and research hospitals have acquired EOS M series machines to locally manufacture patient-specific implants (reducing dependency on imports). Furthermore, EOS polymer SLS printers are used in India for automotive prototyping and even batch production of components like automotive electronics housings and customized consumer goods. EOS’s presence in India is supported by local distributors and an EOS India liaison office, ensuring training and service are available for Indian customers.

With India aiming to boost domestic production in defense and healthcare devices, EOS’s proven industrial AM technology is a valuable asset – offering Indian manufacturers a route to produce complex, lightweight parts indigenously. EOS’s role as an AM technology partner will likely expand as the Indian market grows, given the company’s strong track record in industrializing additive manufacturing globally.

4. HP Inc. (3D Printing Division) – Scaling Additive Manufacturing for Production

Overview: HP Inc., a name synonymous with traditional printers and computing, entered the 3D printing arena in the mid-2010s and rapidly became one of the top innovators in additive manufacturing. Leveraging its inkjet expertise, HP introduced Multi Jet Fusion (MJF) technology in 2016, aiming squarely at high-speed polymer part production. By 2026, HP’s 3D Printing and Digital Manufacturing division (based in Barcelona, Spain and Palo Alto, California) has grown into a major player focused on industrial plastic and metal 3D printing solutions.

While HP’s overall corporate revenues are dominated by PCs and 2D printers, its 3D printing business has been expanding quickly – industry analysts estimate HP’s 3D segment revenue in the few hundreds of millions USD, placing it among the top five 3D printer manufacturers globally. HP differentiates itself by targeting volume manufacturing: its vision is not just prototyping but mass customization and digital production in factories.

Technologies and Products: HP’s flagship technology, Multi Jet Fusion, is a powder-bed fusion process but distinct from laser sintering – it uses arrays of inkjet heads to selectively deposit fusing and detailing agents onto polymer powder layers, which are then fused by infrared energy. This process enables very rapid build times and excellent part isotropy. HP’s main offerings, the Jet Fusion 5200/5400 series, produce nylon (PA12, PA11, etc.) parts with fine detail and high throughput, ideal for functional prototypes and end-use production.

A single HP MJF machine can output tens or hundreds of parts in a day, and HP sells them in integrated “production cell” setups with build units and processing stations for continuous use. In 2020s, HP expanded materials to include elastomers and polypropylenes, and introduced color-capable 3D printers (the Jet Fusion 580/380 for full-color prototyping).

Crucially, HP also made a foray into metal 3D printing: it developed Metal Jet technology (binder jetting of metal powders, followed by sintering). The Metal Jet S100 systems began shipping around 2022–2023, targeting volume production of metal parts like stainless steel filters, automotive components, etc.. This puts HP in competition with binder jet specialists. On the software side, HP provides its SmartStream 3D build preparation and has open partnerships for software (Materialise, Siemens, etc.) and materials development (HP took an open-platform approach to allow third-party powders). The company touts its 50+ material options available or in development for MJF and has a Digital Manufacturing Network of partner service bureaus deploying its machines.

Manufacturing Use-Cases: HP’s impact is most visible in scenarios of scaled production and mass customization. A prime example is in the dental aligner industry: SmileDirectClub, a US-based orthodontics company, operates a fleet of 60 HP MJF printers to produce 50,000+ custom mouth mold models per day, over 20 million aligner molds per year, making it one of the largest 3D printing production operations in the world. This exemplifies how HP’s technology enables mass-personalized products (each aligner mold is unique to a patient).

In automotive, companies like Volkswagen and Jaguar Land Rover have used MJF for series production of limited-run plastic parts (spare parts, interior brackets), leveraging the cost efficiency at low-to-mid volumes where injection molding is less flexible. HP’s machines are also used for medical device housings, consumer electronics enclosures, prosthetic devices, and more – anywhere a few thousand high-quality plastic parts are needed quickly. The ability to produce functional parts with good surface finish and mechanical properties straight out of the printer (with minimal post-processing) has been a selling point of MJF.

Growth and Developments: Since entering the market, HP has rapidly iterated its 3D printing tech. It improved the cooling and handling with the 5200 series, introduced a white parts printer (Jet Fusion 5420W) to allow producing white-colored parts for healthcare uses, and continually dropped per-part costs. HP frequently highlights that its 3D printing solution can be 10x faster than some legacy processes and competes with injection molding at certain volumes.

In 2024, HP announced the Jet Fusion 5400 series with enhancements in automation and part quality consistency. On the Metal Jet side, after pilot programs with partners (like GKN for automotive filters), HP ramped up commercial availability of Metal Jet, positioning it for industries like automotive and consumer goods for thousands of metal parts production. HP’s strategy involves partnering with manufacturing giants (e.g. automotive suppliers, contract manufacturers) to insert its 3D printers into production lines. The company also emphasizes sustainability – MJF technology has high powder reusability (unused powder can be recycled for future jobs), reducing waste.

By 2026, HP is one of the main driving forces pushing additive manufacturing into factory-scale production. Its presence also signifies the entry of traditional printing industry leaders into AM, bringing strong R&D and global support capabilities. HP likely continues to expand material offerings (perhaps composites, flame-retardant materials for aerospace, etc.) and improve throughput to further lower cost-per-part, aiming to unlock more high-volume applications.

Indian Market Impact: HP’s 3D printing solutions have garnered interest in India, especially for manufacturing and healthcare. Several Indian service bureaus and startups (such as SmileAligner in orthodontics or automotive prototyping firms) have adopted HP Multi Jet Fusion printers to deliver end-use parts with fast turnaround.

The appeal is the combination of speed and part quality – for instance, an Indian automotive supplier can 3D print spare parts or tooling on-demand in a day rather than waiting weeks for tooling. In the dental sector, as the clear aligner market grows in India, local companies are considering MJF farms akin to SmileDirectClub’s to produce molds for aligners at scale. HP has also set up a 3D Printing Center of Excellence in India in collaboration with partners to demonstrate its technology’s capabilities to Indian industry.

The relatively lower operating cost of MJF (due to reusing powder and fast cycle) is attractive for cost-sensitive markets like India. Moreover, HP’s established brand and support network in India (from its traditional printers business) give it a customer service edge – users can expect reliable maintenance and training. As the Indian manufacturing sector modernizes, HP’s vision of digital manufacturing aligns with initiatives like “Make in India” by enabling localized, flexible production. We can expect to see increasing deployment of HP 3D printers in India’s automotive OEMs, consumer product startups, and medical device manufacturers as a way to shorten supply chains and customize products for the local market.

5. GE Additive (Colibrium Additive) – GE’s Industrial Metal 3D Printing Arm

Overview: GE Additive, recently rebranded as Colibrium Additive in 2024, is the additive manufacturing division of General Electric – focused on metal 3D printing technologies. Established in 2016 under GE, the business quickly scaled through the high-profile acquisitions of Concept Laser (Germany) and Arcam AB (Sweden) in late 2016, bringing in laser and electron-beam powder bed fusion expertise. Now operating as part of GE Aerospace after GE’s corporate restructuring, Colibrium Additive is a leading provider of industrial metal AM machines, metal powders, and services to industries like aerospace, healthcare, and automotive.

GE’s venture into additive was driven by its own use-case: GE Aviation famously designed a fuel nozzle for jet engines that could only be made via 3D printing, demonstrating the technology’s value. As of 2026, GE Additive/Colibrium stands as a top metal AM manufacturer by revenue – it has delivered hundreds of machines globally (particularly the Concept Laser M Line series and Arcam EBM machines), and its estimated annual revenue (including machines, powders, and services) is in the few hundred millions USD. Backed by the might of GE, Colibrium Additive’s mission is to drive additive adoption in heavy industries.

Technologies: Colibrium Additive has a multi-pronged metal AM portfolio inherited from its acquisitions and in-house R&D:

- Laser Powder Bed Fusion (LPBF): From Concept Laser (now absorbed into Colibrium), it offers the Mlab (small), M2 Series 5, and the large modular X Line (renamed GE Additive Concept Laser M Line) systems. These use lasers to melt metal powder (materials like Ti-6Al-4V, aluminum, nickel superalloys, steels) and are known for high build quality and in-situ monitoring. The latest machines incorporate multiple lasers for productivity and closed-loop quality controls.

- Electron Beam Melting (EBM): Inherited from Arcam EBM, this technology uses a high-power electron beam in a vacuum to fuse metal powder. Arcam’s flagship Spectra series (e.g. Spectra L) can print high-temperature materials like titanium aluminide and is popular for orthopedic implants and aerospace blades due to its fast build of multiple parts at once. Colibrium continues to advance EBM (now termed EB-PBF under GE) for superior material properties and low residual stresses.

- Binder Jetting: GE Additive has also been developing a metal binder jet platform (project name H2 and later the Series 3 binder jet) targeting mass production of small metal parts (e.g. automotive fuel injectors). This complements GE’s polymer binder jet (via the acquisition of a startup in 2021). As of 2025, GE was piloting this with partners for volume manufacturing.

- Materials and Software: Colibrium Additive produces metal powders through its AP&C unit (Advanced Powders & Coatings, in Canada) for titanium, nickel, etc., ensuring supply of high-quality feedstock. It also provides software tools for build prep (like Geomagic software integrated for support generation) and offers engineering consultancy to help customers qualify parts.

Industry Applications: Being part of GE Aerospace, it’s no surprise that aerospace is a primary focus. GE’s own Aviation division has industrialized AM for critical engine components: the LEAP jet engine fuel nozzle (manufactured by Concept Laser printers) was a breakthrough – consolidating 20 parts into 1 and cutting weight by 25%. GE Additive’s machines are used by other aerospace players to print parts like rocket engine injectors, satellite components, and engine brackets. The medical implant industry is another key market – Arcam’s EBM technology has long been used by orthopedic companies (like Exactech, Lima) to produce tens of thousands of patient-specific hip implants and spinal cages with porous surfaces for bone integration.

GE Additive supports these customers with specialized machines and powder alloys (e.g. medical-grade titanium and cobalt-chrome). In the automotive sector, GE Additive’s binder jet is positioning to enable production of metal filters, small engine parts, and decorative pieces at volumes of tens of thousands. High-end automotive and motorsport teams also use its laser systems for complex components (e.g. gearbox housings, heat exchangers). Additionally, energy and industrial companies utilize GE’s AM tech for parts like fuel nozzles in power turbines and bespoke tooling.

Recent Developments: In April 2024, GE Additive rebranded to “Colibrium Additive” to align with GE’s split into separate companies (GE Aerospace, GE Vernova, GE HealthCare). The new name signifies “collaborative equilibrium,” highlighting working closely with customers and balancing the AM ecosystem. Along with the rebrand, GE announced the retirement of the Concept Laser and Arcam brand names – moving forward, all products carry the Colibrium Additive branding. This streamlining is meant to present a unified face to the market and integrate the product lines more tightly.

GE Additive also underwent leadership changes, with a renewed mandate to make the business profitable (GE invested heavily in AM during 2016–2019; by mid-2020s the focus shifted to ROI). The business has been working on next-gen machines (e.g. the Concept Laser X Line successor with larger build volume and automated part handling, and improved EBM machines with higher beam power). It also emphasizes partnerships in academia and government to advance standards and certification for AM in regulated industries.

As of 2025, industry analysts estimated GE Additive’s annual revenue around $500–600 million, indicating it quickly became one of the top AM vendors. However, profitability has been elusive; thus, Colibrium is likely focusing on more cost-efficient operations and targeting high-margin services (maintenance contracts, engineering services). GE’s advantage is that it is a practitioner of AM (using the tech in its own products), lending credibility when selling to other companies.

Indian Market Impact: GE has a long history in India through GE Aviation and other divisions, and it has leveraged that presence to promote additive manufacturing. GE’s India Technology Center (Bengaluru) houses some of GE’s 3D printers (Concept Laser machines) used for R&D on aviation components and to train engineers in AM design. GE Additive has also engaged with Indian service bureaus and government bodies: for instance, the Indian Air Force’s 3BRD repair depot worked with Wipro and Concept Laser to 3D print spare parts for legacy aircraft.

The Indian Navy explored using AM for warship components, with GE Additive showing possibilities using its technology. In healthcare, a few Indian hospitals in collaboration with global partners have used Arcam EBM printers for making personalized implants for patients – though this is in early stages. As India pushes to build indigenous aerospace and defense hardware, metal 3D printing is seen as a strategic capability (reducing dependence on imported parts).

GE Additive/Colibrium, with its cutting-edge metal printers, is positioned to supply this need. It has the credibility of GE’s own use cases (for example, if HAL or a private Indian firm aims to print an engine component, GE can share its expertise from LEAP engine part qualification). Moreover, GE Additive has partnered with Indian academia (IITs) on AM research, helping develop local talent skilled in these machines. In summary, GE Additive (Colibrium) acts as both a vendor and an knowledge partner in India’s journey to adopt metal additive manufacturing, particularly for high-value sectors like aerospace, defense, and healthcare devices.

6. Desktop Metal, Inc. – Binder Jetting and Digital Manufacturing Innovator (Now part of Nano Dimension)

Overview: Desktop Metal, founded in 2015 in Massachusetts (USA), burst onto the scene with a mission to make metal 3D printing more accessible and faster. Over the next decade, the company became known for its office-friendly metal printers and high-speed binder jetting technology, as well as a series of bold acquisitions that expanded its portfolio into polymers and dental solutions. By 2026, Desktop Metal’s journey has been eventful: once a celebrated unicorn startup that went public via SPAC in 2020, it later faced market challenges and was acquired by Nano Dimension in April 2025.

Now as a subsidiary under Nano Dimension, Desktop Metal’s technologies continue to play a prominent role in the AM industry. The company’s influence is reflected in its broad product lineup, which includes systems for prototyping to mass production in metals, composites, and photopolymers. Combined revenues of Desktop Metal (pre-acquisition) and its acquired businesses were in the ~$200+ million range in 2024, placing it among the top 3D printer companies by revenue.

Technologies and Products: Desktop Metal’s core innovation was the Studio System launched in 2017 – a benchtop metal printer using Bound Metal Deposition (extruding metal-polymer rods), paired with a furnace for sintering. This offered an “office-friendly” metal prototyping solution with safer material handling than powder processes. However, Desktop Metal’s bigger play was in binder jetting for mass production.

It developed the Production System (P-50), a large binder jet printer using the company’s proprietary Single Pass Jetting (SPJ) technology, claimed to be one of the fastest metal 3D printing methods (jetting binder across a full width in one pass). The P-50 (and the smaller P-1) can print thousands of cubic centimeters per hour in metals like steel and copper, aimed at volume manufacturing of metal parts at costs competitive with casting.

Through acquisitions, Desktop Metal also entered other segments: it acquired ExOne in 2021 – a pioneer of industrial binder jetting (metal and sand). This gave Desktop Metal a stronghold in sand 3D printers for casting molds (ExOne’s machines are used in foundries worldwide) and additional metal/material expertise. It also acquired EnvisionTEC in 2021, a veteran in DLP photopolymer 3D printers, which brought a line of industrial resin printers (now branded ETEC) for applications like jewelry casting, dental models (the Envision One printer), and bioprinting.

Other acquisitions included Adaptive3D (resins), Aerosint (multi-material printing tech), and even a wood 3D printing startup (Forust, for printing wood-like composites). The result is that Desktop Metal’s product portfolio by 2025 spanned: metal binder jetting systems, sand casting printers, DLP resin printers, fiber composite printers (it launched Fiber™ system for continuous fiber composites), and more. Few companies had such breadth.

Market Applications: Desktop Metal targeted production use-cases head-on. Its binder jetting systems allow mass production of metal parts like metal injection molding (MIM) would. Example parts include automotive drivetrain gears, watch components, tool inserts – made in batches of thousands with binder jet and sintering. One notable application has been in the consumer electronics realm, where binder jetting can produce complex copper or stainless steel parts for devices in volume. ExOne’s sand printers serve the foundry industry: foundries in automotive and aerospace use them to print sand molds and cores for casting engine blocks, turbine blades, etc., greatly speeding up casting workflows.

The EnvisionTEC acquisition gave DM a foothold in digital dentistry and jewelry – that business (now called ETEC) supplies 3D printers and materials to dental labs for making orthodontic models, surgical guides, and to jewelers for casting patterns. These are high-demand verticals; for instance, EnvisionTEC’s 3D printers have been popular among Indian jewelry manufacturers for creating intricate wax models quickly. Desktop Metal’s composite printing (Fiber) is used for making strong carbon-fiber reinforced parts for tooling in aerospace and industrial machines.

Corporate Rollercoaster and Acquisition: Desktop Metal’s aggressive growth strategy (via acquisitions and rapid R&D) led to very fast expansion but also substantial financial losses. After its public listing, the company struggled with profitability, and its stock value dropped significantly from early highs. In 2023, as mentioned earlier, Desktop Metal agreed to merge with Stratasys to form a combined giant, but that merger was terminated due to Stratasys shareholder opposition. Subsequently, another suitor emerged: Nano Dimension, an Israeli-American firm specializing in 3D-printed electronics, which itself had tried to take over Stratasys. In a surprising turn, Nano Dimension ended up acquiring Desktop Metal in 2025 for $179 million (a fraction of DM’s past valuation).

The acquisition, completed in April 2025, made Desktop Metal a wholly-owned subsidiary of Nano Dimension, which seeks to integrate DM’s portfolio with its own electronics printing tech. Under Nano Dimension’s umbrella, Desktop Metal’s leadership changed – founder/CEO Ric Fulop stepped down from the board (though initially stayed in an executive role) and Nano’s management took over, aiming to streamline costs and focus the product lines. The goal is to achieve a sustainable business model from the combined operations.

For customers, the short-term impact is minimal – Desktop Metal continues to sell and support its printers, now with presumably stronger financial backing after restructuring. Nano Dimension indicated it will “realign resources toward highest-potential product lines”, which likely means focusing on the most promising technologies like Production System binder jetting and key markets (dental, jewelry, etc.). Some less profitable or overlapping lines may be phased out or consolidated with Nano’s offerings.

Outlook: By 2026, Desktop Metal’s innovative binder jetting tech remains highly influential. The company (under Nano) will likely emphasize industrial adoption of binder jet for mid-to-high volume manufacturing, presenting it as a complement or alternative to casting and machining. We might see further integration of 3D-printed electronics (Nano’s forte) with DM’s parts, potentially printing circuitry into mechanical parts. The combination of polymer, metal, and composite printing solutions under one roof gives them a unique cross-selling opportunity – a one-stop for various additive needs.

Indian Market Impact: Desktop Metal’s technologies address several needs relevant to India’s manufacturing landscape. For instance, casting and foundry is a big industry in India – ExOne (now part of DM) had already sold sand printers to Indian foundries or universities to produce casting molds faster. This can significantly reduce tooling lead times for India’s automotive castings sector. In metal part production, Indian automotive and aerospace suppliers could use binder jet systems to make complex metal parts locally in medium volumes without expensive tooling – aligning with the “Atmanirbhar” self-reliance initiative.

The affordability of some DM systems (Studio System for example) also opened metal 3D printing to smaller Indian R&D labs and startups that couldn’t invest in large laser metal printers. On the dental and jewelry side, EnvisionTEC (ETEC) has an established user base in India; many jewelry manufacturers in Mumbai and Surat adopted EnvisionTEC Perfactory printers over the last decade to make wax models for gold casting, due to their high precision. This trend continues, with newer ETEC models providing higher throughput. In the dental realm, as India’s dental industry modernizes, the uptake of 3D printed aligners and crowns is rising – ETEC’s 3D printers and materials are likely part of that supply chain.

With Desktop Metal now under Nano Dimension, Indian customers might see a more stable support and possibly better pricing (given Nano’s capital infusion). Nano Dimension also has an India presence for its PCB printers; this could extend to promoting Desktop Metal’s portfolio. In summary, Desktop Metal’s mix of technologies is quite relevant to India’s drive to modernize manufacturing – from rapid casting patterns and dental devices to exploring mass production of metal parts – making it a notable player in the Indian AM scene in the coming years.

7. Formlabs, Inc. – Desktop Professional 3D Printing Leader (Resin & SLS)

Overview: Formlabs is a standout success story in the 3D printing industry, known for bringing professional-grade 3D printing to the wider engineering and maker community. Founded in 2011 by MIT Media Lab students and headquartered in Massachusetts, USA, Formlabs pioneered the market for affordable, high-quality resin 3D printers. Its flagship product line – the Form series of desktop stereolithography (SLA) printers – drastically lowered the cost barrier for high-resolution 3D printing, making it accessible to small businesses, dental clinics, jewelers, and product designers worldwide.

Over the past decade, Formlabs grew from a Kickstarter startup to one of the largest 3D printer manufacturers by unit volume (tens of thousands of machines sold) and achieved unicorn valuation (over $2 billion). As of 2026, Formlabs remains a privately held company, reportedly with annual revenues in the nine-figure range (estimated $100–200+ million), putting it among the top AM companies in terms of sales.

Technologies and Products: Formlabs’ core technology is stereolithography (SLA) using a laser and resin. The company’s breakthrough was the Form 1 (launched 2012) and subsequent Form 2/3/3+ printers – compact desktop machines that delivered professional print quality (25–50 micron layers, smooth surface finish) at a price under $5,000, a fraction of industrial SLA machines.

The latest Form 3+ and Form 3B+ (the B is a variant optimized for biocompatible resins) utilize Formlabs’ proprietary Low Force Stereolithography (LFS), a refined SLA process that reduces peel forces for improved accuracy and reliability. Formlabs also expanded into Selective Laser Sintering (SLS) for plastics with the Fuse 1 benchtop SLS printer (launched 2021) and later Fuse 1+ 30W, which sinter nylon powders. This brought industrial SLS capability (previously the domain of large EOS machines) into a small business setting at relatively low cost.

A key aspect of Formlabs is its focus on materials: it offers a wide library of over 40 proprietary resins – ranging from standard ABS-like and tough engineering resins to flexible, high-temp, castable (for jewelry), dental resins (certified for aligners, surgical guides), and even a biocompatible resin for medical devices. This materials ecosystem enables users to make application-specific parts on the same Form printer. Formlabs also provides an integrated software (PreForm) for easy print setup and an array of finishing tools (like the Form Wash and Cure units to clean and cure SLA parts). By owning the end-to-end solution and simplifying user experience, Formlabs became very popular in disparate fields.

Market and Applications: Formlabs printers are ubiquitous in product design and prototyping – thousands of design firms, hardware startups, and engineering departments use Form 3s to quickly iterate product designs with fine detail (for instance, consumer electronics enclosures, medical device prototypes, architectural models). In the dental industry, Formlabs made huge inroads; its Form 3B printers plus dental resin line allowed small dental labs and even clinics to 3D print custom dental models, clear aligner molds, crown and bridge patterns, and dentures in-house at low cost, revolutionizing digital dentistry.

By mid-2020s, Formlabs claimed a large share of the dental 3D printer market with tens of thousands of dental professionals as users. In healthcare, hospitals use Formlabs printers to create patient-specific surgical guides, prosthetic prototypes, and educational models (taking advantage of biocompatible and sterilizable resins). Jewelry makers utilize Formlabs castable wax resin to print intricate ring models for direct investment casting. The Fuse 1 SLS has opened up functional part production – e.g., small manufacturers now print short-run functional nylon parts (like clips, jigs, robotic components) without needing an expensive EOS system. Formlabs printers have even gone to space (a Form 2 was used on the International Space Station for experiments).

The company also built an online community and knowledge base, fueling adoption across universities and fab labs for education and research. With reliability and user-friendliness improved over successive models, many companies deployed farms of Formlabs printers for low-volume production (like hearing aid shells or camera accessories).

Growth and Developments: Formlabs’ strategy has been organic growth through product improvement and market expansion. It raised substantial venture funding (over $250M) to fuel R&D and global marketing. Recent developments by 2025 include the Form 3+ update for faster print speeds, the Build Platform 2 with quick-release technology, and new resins like polyurethane resins for tougher parts. Formlabs also launched the Automation Ecosystem around 2022–2023, featuring the Form Auto (an automated part removal system) and Fleet Control software, aiming to enhance throughput by letting multiple prints run in succession without human intervention – a nod towards more automated, scalable production using many desktop units.

On the SLS side, the introduction of the Fuse 1+ 30W (with a more powerful laser) enabled printing higher-performance materials like carbon-fiber reinforced nylon and faster cycle times, making SLS more viable for production quantities.

Thanks to these innovations, Formlabs has maintained its position in a more crowded low-cost SLA market (where competitors like Anycubic, Elegoo from China emerged for hobbyists, and 3D Systems re-entered with Figure 4 Modular for industrial). Its focus on professional and medical users, backed by material quality and regulation compliance, gives it an edge. By 2026, Formlabs likely explores new frontiers such as larger-format systems or even continuous printing techniques, but its core strength remains its accessible yet capable printers and broad customer base.

Indian Market Impact: Formlabs has a significant user base in India, aligning well with the needs of Indian SMEs, labs, and clinics. The relatively lower cost and ease of use of Form printers make them attractive for Indian businesses that cannot invest in very expensive industrial machines. For instance, many Indian dental labs and orthodontists adopted Formlabs Form 3B printers to produce aligner molds and dental models domestically, cutting down time and cost versus outsourcing or older manual methods. This has contributed to the growth of clear aligner startups in India who rely on in-house 3D printing.

In product design and startups, Formlabs is often the go-to for creating prototype enclosures, hardware device casings, etc., enabling India’s vibrant startup ecosystem to iterate designs quickly without outsourcing prototyping overseas. Jewelry manufacturers in India’s gold markets (Surat, Mumbai) also use Formlabs castable resin to make custom jewelry pieces, benefitting from the fine detail to cater to consumer customization trends. Academic institutions and engineering colleges in India have installed Formlabs printers in their innovation labs to train students in AM and to fabricate project parts.

Crucially, Formlabs established an official presence and distribution in India early, ensuring customer support and resin supplies are readily available. As India is a price-sensitive market, the combination of Formlabs’ competitive pricing and high quality hit a sweet spot. For more industrial needs, the Fuse 1 SLS offers Indian companies a way to do small batch production of strong plastic parts (for example, a drone startup printing nylon drone parts, or an automotive supplier making replacement parts on-demand) without investing half a million dollars in large SLS equipment.

Overall, Formlabs has arguably democratized professional 3D printing in India, empowering a wide range of users – from dentists to device makers – to leverage additive manufacturing, and it will likely continue to be a key player as those user segments expand.

8. Markforged, Inc. – Composite and Metal 3D Printing for Industrial Applications

Overview: Markforged, founded in 2013 in Massachusetts (USA), is known for its unique focus on composite 3D printing and accessible metal printing solutions, aimed primarily at industrial end-users for tooling and functional part fabrication. Markforged’s claim to fame was introducing the world’s first continuous carbon fiber composite 3D printer (the Mark One) in 2014, enabling parts with metal-like strength by embedding fibers in nylon. Since then, Markforged has broadened its lineup to include a range of industrial composite printers and a compact metal printer (Metal X).

The company went public in 2021 via SPAC and, as of 2025, generates on the order of ~$80–100 million in annual revenue. While smaller than some rivals, Markforged has a strong brand in manufacturing circles for reliable, workshop-friendly machines. Its strategy revolves around what it calls the “Digital Forge” – a platform of software, materials, and printers that allow manufacturers to fabricate end-use parts on demand. By 2026, Markforged remains a significant player for factory-floor additive manufacturing, especially for tooling, jigs and fixtures, spare parts, and functional prototypes.

Technology and Products: Markforged’s product line centers on two main technologies:

- Continuous Fiber Fabrication (CFF): This is Markforged’s proprietary method where a base thermoplastic (usually nylon or Onyx – a nylon with micro carbon fiber fill) is printed via FFF, while at the same time continuous strands of fiber (carbon fiber, Kevlar, or fiberglass) can be laid into the part along critical load paths. The result is a composite part with vastly higher strength and stiffness than plastic alone – often comparable to aluminum yet much lighter. Printers like the Markforged X7 (industrial series) and Mark Two (desktop series) use this tech. They have dual extrusion nozzles: one for plastic, one for continuous fiber. These printers are commonly used to make strong tooling, brackets, robot arm grippers, molds, etc., that can replace machined aluminum in many cases. Markforged’s Onyx material (chopped carbon fiber filled nylon) itself offers good rigidity, and adding continuous fiber reinforcement elevates performance further.

- Bound Powder Metal Printing: Markforged’s Metal X system (launched 2017) uses a Bound Metal Deposition approach similar conceptually to Desktop Metal’s Studio – it extrudes rods of metal powder mixed with polymer binders to create a “green” part, which is then washed and sintered in a furnace to produce a dense metal part. The Metal X made metal printing more office-friendly, albeit with limitations on part size and some precision loss during sintering. It can print materials like stainless steels (17-4PH, 316L), tool steels, Inconel, and copper. Markforged provided an end-to-end system including a wash/debinder and a sintering furnace, targeting machine shops and maintenance departments that need one-off metal parts (e.g. replacement parts, cutting tools, molds) without the cost or complexity of laser powder printers.

Additionally, Markforged offers Eiger software, a cloud-based platform to prepare prints and manage a fleet of printers, integrating material profiles and fiber layup optimization. The company places emphasis on ease of use – e.g., minimal calibration, cloud updates, and a uniform software experience across all its printers.

Industry Use-Cases: Markforged’s strongest adoption has been in the realm of manufacturing tooling and operational agility. Factories and machine shops use Markforged X7 printers to fabricate custom jigs, fixtures, assembly guides, and robot end-effectors with quick turnaround, improving their production efficiency. For example, in an automotive assembly line, instead of machining a fixture in aluminum (which may take weeks externally), an engineer can print a carbon fiber-reinforced fixture overnight on a Markforged, use it on the line, and if it breaks or needs modification, simply iterate the design.

This flexibility and the material’s durability (carbon fiber composites can handle significant stress and moderate heat) have saved time and cost. Aerospace companies have used Markforged parts for non-flight tooling and even some flight-approved components (like ULTEM-filled Kevlar brackets on satellites in a few cases). The Metal X, while not delivering the same quality as high-end metal printers, has found a niche for maintenance and repair operations (MRO) and low-volume fabrication – for instance, a factory can print a replacement part for a broken machine (like a sensor mount or a small linkage) in steel overnight to reduce downtime, or a tooling manufacturer can quickly make a custom cutting tool geometry in H13 steel and heat-treat it.

Markforged’s continuous fiber parts also got attention in the defense sector – the U.S. military deployed some Markforged units in forward operating bases to print spare parts and drone components on site. Its relatively compact, robust printers fit well in such scenarios.

Recent Developments: In 2022–2025, Markforged updated its hardware and materials. It released the FX20 in late 2021, a large-format, high-temperature composite printer capable of printing ULTEM (PEI) thermoplastic with continuous fiber – this targets aerospace and automotive customers needing higher temperature resistance and bigger parts (the FX20 can produce parts nearly an order of magnitude larger than the desktop units). Markforged also added more metal materials to Metal X (like pure copper for electrical applications).

On the corporate side, Markforged acquired a few smaller companies, such as Teton Simulation (for software to analyze part strength) and Digital Metal (a Swedish metal binder jet company) in mid-2022, indicating interest in faster metal printing tech. However, by 2024 Markforged decided to discontinue the Metal X system in favor of focusing on the acquired binder jet (Digital Metal’s solution) for its future metal offerings – a significant pivot acknowledging that binder jet may scale better for production than the filament approach. They branded the binder jet line as PX100 (based on Digital Metal’s proven tech for small intricate metal parts). This move shows Markforged aligning more with production-oriented metal printing for the future.

Financially, Markforged faced headwinds in 2022–2023 with slower growth and had to streamline operations (its stock price fell post-SPAC). The company, however, has maintained a decent cash reserve and continues to innovate within its niche.

Indian Market Impact: Markforged’s proposition of on-demand strong parts resonates with many Indian manufacturers, especially SMEs who need cost-effective tooling and quick part turnaround. In India, automotive component suppliers and assemblers have adopted Markforged composite printers to create fixtures and gauges used in manufacturing lines, improving their responsiveness and reducing outsourcing of tooling.

The aerospace and defense sector in India – e.g., HAL or DRDO labs – have explored Markforged printers for producing lightweight tooling and even some test parts for UAVs or missiles, given the appeal of high strength-to-weight ratio of carbon fiber parts. The relatively user-friendly nature of Markforged machines (including the cloud-based Eiger software and auto calibration features) suits Indian companies that may not have extensive prior AM experience.

For metal parts, some Indian R&D centers and startups have used the Metal X to experiment with printing metal prototypes or replacement parts, though adoption has been limited by the need for post-processing and the cost of metal powder consumables. With Markforged’s shift to binder jet (via Digital Metal tech), we might see Indian service bureaus showing interest for small precise metal parts (like jewelry components or electronics connectors) – but that is emerging.

Crucially, Markforged has partnered with local Indian distributors to provide sales and support, and there are documented Indian case studies (for instance, Mahindra Group’s toolrooms reportedly use Markforged printers for tooling). The printers’ ability to function in an office or shop environment without special safety infrastructure is a plus in India. As Indian industry continues modernizing, the idea of a “Digital Forge” where factories have a cluster of printers churning out needed parts on-demand is gaining traction, and Markforged is one of the influencers of this concept. Their composites fill a performance gap between basic plastic printers and costly metal machines, and in cost-conscious markets like India, that balance is very attractive.

9. Creality (Shenzhen Creality 3D Technology Co.) – Global Leader in Consumer 3D Printers

Overview: Creality is a Chinese 3D printer manufacturer that has risen to dominate the desktop consumer and hobbyist 3D printer market worldwide. Founded in 2014 and based in Shenzhen, China, Creality became famous for its low-cost, robust Fused Deposition Modeling (FDM) printers such as the Ender series and CR series. By focusing on affordability, open-source designs, and community feedback, Creality has shipped hundreds of thousands (if not millions) of 3D printers globally – far more units than any industrial maker – and achieved revenues estimated in the hundreds of millions of USD, placing it among the top companies by sheer scale.

In fact, as of the mid-2020s, Creality and a few peers have propelled consumer 3D printing growth; one analysis in 2023 speculated Creality’s revenue around $600+ million, which would rival or exceed some long-established industrial firms. Creality’s influence is tremendous in terms of democratizing 3D printing access, making it possible for educators, hobbyists, and small entrepreneurs to own a capable 3D printer for a few hundred dollars.

Products and Market Segment: Creality’s portfolio primarily consists of FDM 3D printers using plastic filament. Its most popular models include:

- Ender-3 series: A landmark product launched in 2018, the Ender-3 (priced around $200) was an open-frame kit that delivered surprisingly good print quality for its price. It became a best-seller and has since seen iterations (Ender-3 Pro, V2, S1, etc.). This model and its successors are widely used by beginners and makers globally.

- CR-10 series: A larger-format, open-frame printer popular for printing big props, cosplay items, and functional parts. Its simplicity and modifiability made it a community favorite.

- Resin LCD Printers: In addition to FDM, Creality also offers budget-friendly resin printers (e.g. LD-002, HALOT series) that use LCD masking technology for finer detail, targeting hobbyists who want to print figurines, miniatures, dental models, etc. at low cost.

- CR Series Professional: Creality has some higher-end models like CR-6 SE (focusing on user-friendly features) and CR-30 (a belt 3D printer for continuous printing) demonstrating innovation beyond basics.

Creality’s business model benefits from the open-source RepRap community – many of its designs are derived from or inspired by open-source predecessors (and Creality in turn shared some of its design files). This has led to a huge aftermarket of modifications and upgrades (for example, users adding auto-bed leveling probes, better extruders, enclosures, etc. to Creality machines). The large user base and community forums mean problems are quickly identified and addressed either by Creality in new versions or by user mods. In essence, Creality provides a baseline machine which advanced users can tinker with to achieve results comparable to much pricier printers.

Global Reach and Scale: Creality, alongside a few other Chinese manufacturers, has essentially flooded the market with low-cost printers, dramatically expanding the user population of 3D printing. They reportedly shipped over a million units cumulatively by early 2020s. In 2020, when stay-at-home orders drove hobbyist interest, Creality saw a sales boom. By 2025, Creality’s footprint includes strong sales in North America, Europe, and emerging markets, often via e-commerce (Amazon, Aliexpress) and a network of resellers. The company’s sheer volume advantage yields economies of scale allowing aggressive pricing.

While aimed at consumers, Creality printers are also used by professionals on a budget – e.g., an engineering student prototyping a project or a small business making custom parts. Many educational institutions use fleets of Ender-3s for student use given their low cost. The reliability and quality out-of-the-box might not match higher-end brands, but for many use cases, especially with fine-tuning, they are sufficient.

Innovation and Competition: Creality faces competition from other Chinese brands like Anycubic, Elegoo (particularly in resin printers), Prusa Research (in the higher-end hobbyist segment), and more recently Bambu Lab – a well-funded Chinese startup that in 2022 launched the X1 series with features like multicolor printing and speed, directly challenging Creality’s market by offering more advanced tech (albeit at a higher price). Creality has responded by improving features (e.g., adding auto-bed leveling in newer models, direct drive extruders in some, and even multi-color capability in the Ender-3 V2 Color engine). Creality also invests in community engagement – e.g., sponsoring maker events and listening to feedback.

One of Creality’s innovations is the CR-30 “PrintMill”, co-developed with community figure Naomi Wu, which has a conveyor belt for continuous printing; it’s niche but shows Creality’s willingness to explore new concepts. Additionally, Creality introduced the K1 and K1 Max in 2023/2024, which are CoreXY high-speed printers aiming to catch up with Bambu Lab’s speed and include enclosed chambers and better sensors.

Despite new entrants, Creality’s combination of price and an entrenched community support system keeps it very competitive.

Indian Market Impact: In India, Creality printers are extremely popular among hobbyists, educators, and small businesses due to their affordability. Many Indian makerspaces and engineering colleges have Creality Ender or CR models for student projects. The availability of low-cost 3D printers from Creality has helped nurture a maker culture in India, where individuals can start 3D printing with a modest investment. This has side benefits: a larger base of people familiar with 3D printing concepts, feeding talent into industry.

Small Indian startups and entrepreneurs have utilized Creality machines for product development and even for small-scale production. For example, a custom jewelry entrepreneur might use a Creality resin printer to make prototypes or molds; a robotics enthusiast might print robot chassis parts on an Ender-3. During crises like the COVID-19 pandemic, Indian volunteers with Creality printers produced PPE components (face shield frames, mask straps) in community-driven efforts, illustrating the utility of having many printers distributed at homes and workshops.

Creality has authorized resellers in India, and their printers are sold through e-commerce platforms locally, making them relatively easy to procure. The support and warranty might not be as strong as what industrial suppliers offer, but the vibrant online forums often fill that gap. As India’s interest in 3D printing grows, Creality is often the entry point for individuals and MSMEs (Micro, Small & Medium Enterprises) to experiment before perhaps scaling up to industrial equipment.

In summary, Creality represents the “consumerization” of 3D printing, complementing the industrial advancements by other companies. Its impact is seen in the sheer number of printers in operation worldwide. By 2026, Creality continues to refine its products, pushing more feature-rich yet affordable models, and its reach in India and globally ensures that 3D printing knowledge and usage penetrate far beyond large companies – into homes, classrooms, and small workshops, effectively expanding the future talent and market for additive manufacturing.

10. Carbon, Inc. – Digital Light Synthesis for High-Volume Production

Overview: Carbon is a Silicon Valley-based 3D printing company known for its proprietary Digital Light Synthesis (DLS) technology – a form of fast resin 3D printing – and for pioneering a subscription-based business model. Founded in 2013 (Redwood City, California) by Joseph DeSimone and colleagues, Carbon gained prominence in 2015 with a spectacular TED talk unveiling a 3D printer that could produce parts 25-100 times faster than traditional SLA, by “pulling” continuous objects out of a resin vat using oxygen-permeable optics.

Carbon’s vision has been focused on mass production and end-use functional parts, rather than prototyping. Over the past decade, Carbon raised over $600 million from investors and achieved unicorn status. While still private and not disclosing all finances, Carbon’s valuation and marquee customers underscore its influence; it is one of the top polymer 3D printing innovators, often cited alongside industry leaders. By 2026, Carbon’s technology is deployed for producing millions of real-world products, especially in consumer goods and healthcare, showcasing how additive manufacturing can scale to high-volume manufacturing.

Technology: Carbon’s DLS (also known initially as CLIP – Continuous Liquid Interface Production) uses a digital light projector (like DLP) to cure photopolymer resin, combined with a permeable window that allows oxygen to inhibit curing at the interface. This creates a “dead zone” of uncured resin near the window, enabling the part to be pulled continuously without layer-by-layer stops, significantly speeding up the process and improving layer adhesion (resulting in isotropic properties).

Carbon’s flagship printers include the Carbon M series (M1, M2) and the larger L1. The L1, for example, has a build area large enough to print multiple midsoles for shoes at once. Carbon’s printers are Internet-connected and sold via subscription (companies pay an annual fee which covers the machine, software, updates, and support rather than a one-time purchase).

A major part of Carbon’s offering is its engineered resin materials, many of which are dual-cure (they cure further in an oven after printing to reach final properties). These include rigid polyurethanes, flexible elastomers (like the proprietary EPU elastomer used in shoe midsoles), dental resins, and even bio-compatible materials. Carbon works closely with customers to develop materials tailored to applications – for instance, they created a unique epoxy-infused material for Riddell football helmet liners to absorb impact, and a fluoride-resistant dental resin for baking trays used in aligner production.

Notable Applications and Partnerships: Carbon’s technology has shined in a few headline-making applications:

- Adidas 4D Shoes: In a high-profile partnership, Adidas used Carbon’s L1 printers and EPU elastomer to produce “Futurecraft 4D” running shoe midsoles with a lattice structure. At its peak, Adidas produced 100,000+ pairs of 4D shoes annually using Carbon printers. This was one of the first instances of 3D printing being used for consumer mass production of a performance product. Although Adidas later scaled back the line, it proved the concept of additive mass production in footwear.

- Dental Aligners: Perhaps even more impactful but less public, Carbon partnered with Align Technology (makers of Invisalign) and other dental aligner companies. Carbon’s L1 printers are used to print tens of thousands of custom dental models daily, which serve as molds for thermoforming clear aligners. Align Technology reportedly produced over 500,000 aligners per day; while not all on Carbon, a good portion has been attributed to Carbon’s fleet, given their throughput. This is arguably the largest volume manufacturing use of 3D printing in the world, valued in billions of dollars of product (Invisalign aligners) annually.

- Medical Devices: Carbon’s technology is used to manufacture surgical guides, dental dentures, and prosthetic sockets. For example, the company partnered to produce personalized hematology testing devices and COVID-19 test swabs during the pandemic. Carbon’s materials like MPU 100 (a medical polyurethane) allow end-use in-body or patient-contact applications.

- Automotive and Industrial: Carbon printers have made production parts for luxury automotive interiors, industrial machinery components (where a tough, durable polymer is sufficient), and even consumer electronics (e.g., Casio used Carbon to manufacture watch components). The emphasis is typically on geometries that benefit from lattice structures or complex shapes, combined with the need for a production-scale quantity.

Business Model and Trends: Carbon’s subscription model means they maintain machines in the field with regular upgrades. Users benefit by always having up-to-date equipment, but they pay continuously (like leasing). This model, along with material sales, yields recurring revenue for Carbon. The strategy also ensures Carbon can push firmware/software improvements – for instance, they’ve improved print speed and added features over time via updates. Carbon expanded globally via partnerships (e.g., in Europe with dental labs, in Asia with manufacturers).

By 2026, Carbon faces competition in the high-speed resin printing arena (companies like 3D Systems with Figure 4, EnvisionTEC/ETEC, and newcomers like Axial3D or Nexa3D offer fast resin printers). However, Carbon’s integrated platform and success stories give it a strong reputation. The company likely continues to innovate in materials (possibly recyclable or biobased resins) and in larger format printing (maybe a bigger L2 printer down the line), as well as software for lattice generation and workflow integration (Carbon’s software helps automatically generate those complex lattices for shoes and helmet pads).

Indian Market Impact: Carbon’s presence in India is currently limited but with growth potential in key sectors. The high cost and subscription nature of Carbon printers have meant adoption is primarily by multinational corporations or top-tier service bureaus rather than small local businesses. However, Indian companies in footwear and dental alignment have certainly observed Carbon’s success. For instance, India has a large footwear manufacturing industry; while most still use traditional methods, some innovative Indian footwear startups or suppliers could follow Adidas’ example using lattice midsoles for high-performance shoes (especially as India moves into more advanced manufacturing). If so, Carbon’s technology (or similar) would be the go-to for achieving the required combination of design freedom and production volume.

In the dental market, India’s clear aligner providers (like Toothsi, Flash, etc.) currently rely on 3D printed molds too – many use multiple cheaper SLA/DLP printers (such as Formlabs or EnvisionTEC). As their volume grows, they might consider Carbon L1 printers to scale production of aligner molds with higher throughput. Additionally, large dental labs that serve global clients might invest in Carbon due to its productivity.

Indian medtech startups working on prosthetics or patient-specific devices could leverage Carbon’s unique materials (for example, printing custom transtibial prosthetic sockets that need strength and comfort). The challenge is the cost barrier, but partnerships or bureau services might bridge that.

To date, Carbon has not announced a direct facility in India, but they have resellers in the APAC region that cover India. As the Indian manufacturing sector climbs the value chain and requires high-end polymer performance parts (and given government initiatives to boost medical device manufacturing, etc.), Carbon’s technology could find a niche. Particularly, if an Indian automotive OEM wanted to do limited-edition custom car interiors or a sports gear company wanted cutting-edge lattice padding, Carbon would be on the shortlist.

In summary, Carbon represents the cutting edge of turning 3D printing into a true manufacturing process. Its impact on the global stage – from shoes to dental devices – serves as an inspiration and template for high-volume use of AM. For Indian industry, Carbon provides a case study of what is possible when additive is pushed to production scale, and in time we may see Indian companies adopting similar approaches as they strive for innovation in design and localized digital manufacturing.

Conclusion: The top 10 additive manufacturing companies of 2026 illustrate the diverse landscape of the 3D printing industry – from long-established giants like Stratasys and 3D Systems leading in polymer and healthcare solutions, to specialized players like EOS and GE Additive driving advances in metal printing for aerospace, to newcomers like Desktop Metal and Carbon reinventing production with binder jetting and ultrafast resin technologies. We also see how desktop and consumer 3D printing (Formlabs, Creality, Markforged) has matured and catalyzed wider adoption, feeding innovation back into industrial realms.

Crucially, these companies span the different sectors of 3D printing: industrial manufacturing (Stratasys, EOS, GE, Desktop Metal, Markforged) enabling factory-floor production and tooling; healthcare and dental (3D Systems, Formlabs, Carbon) delivering patient-specific solutions; aerospace and defense (EOS, GE Additive, Stratasys) producing lightweight certified parts; consumer products (Carbon, HP, Creality) allowing mass customization of goods and democratizing creativity at the hobbyist level. Many of them operate at the intersection of multiple sectors – reflecting the convergence in additive manufacturing where lessons from one domain (e.g. dental aligners) inform approaches in another (mass consumer goods).

From an Indian region perspective, these global leaders are increasingly relevant as India’s aerospace, healthcare, automotive, and MSME sectors embrace 3D printing to improve competitiveness and self-reliance. India’s AM market, though currently a fraction of the global market (around 0.3%), is on a high growth trajectory (25%+ CAGR), fueled by government support and industry awareness.

The technologies and best practices pioneered by the top 10 manufacturers profiled here provide a roadmap for Indian companies and researchers to leapfrog in advanced manufacturing. Collaboration with or adoption of solutions from these leaders – whether it’s installing industrial polymer and metal systems, leveraging accessible desktop printers for design and education, or partnering on materials and applications – will accelerate the maturation of India’s additive manufacturing ecosystem.

In conclusion, the top 10 3D printing manufacturers in 2026 each contribute a critical piece to the AM industry’s evolution. Their innovations in speed, materials, scale, and accessibility are collectively transforming how products are designed and made. As we move forward, we can expect continued consolidation and collaboration among these players (the landscape has already seen mergers and alliances) and relentless progress in technology.

For industry professionals and decision-makers, staying abreast of these leaders’ capabilities is essential to identify opportunities where 3D printing can add value – be it shortening supply chains, enabling personalized products, or creating complex geometries that were previously impossible. The additive manufacturing revolution is well underway, and these companies are at its forefront, driving the world towards a more agile, innovative, and distributed manufacturing future.